Micro-cantilever beam piezoresistive bridge type sensor detecting instrument

A micro-cantilever beam and sensor technology, which is applied in the direction of using an electric/magnetic device to transmit sensing components, can solve the problems of dynamic adjustment, inability to automatically zero and adjust the zero adjustment accuracy, poor contact of mechanical potentiometers, etc., to improve the leveling accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

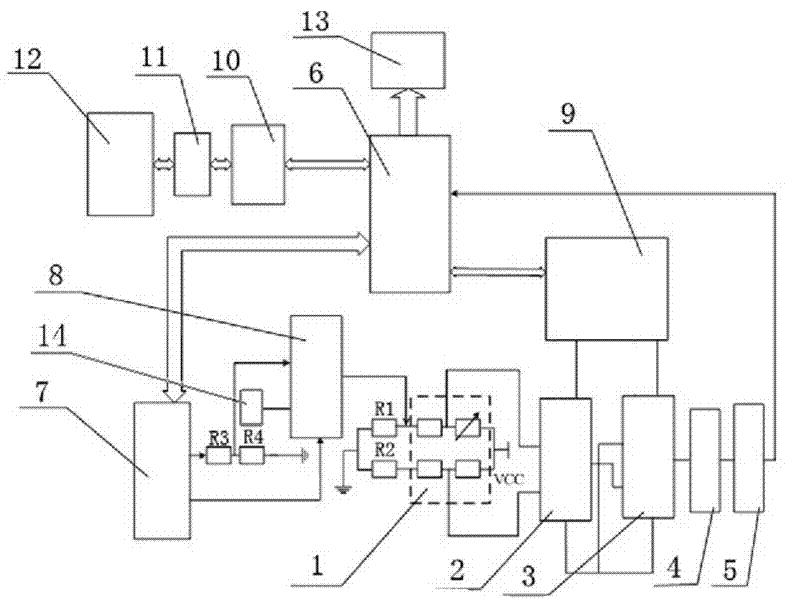

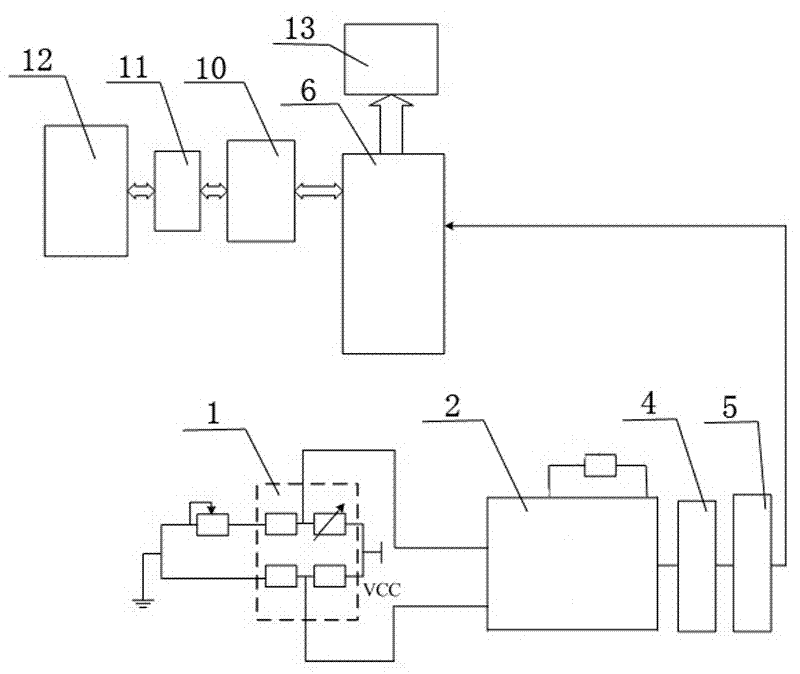

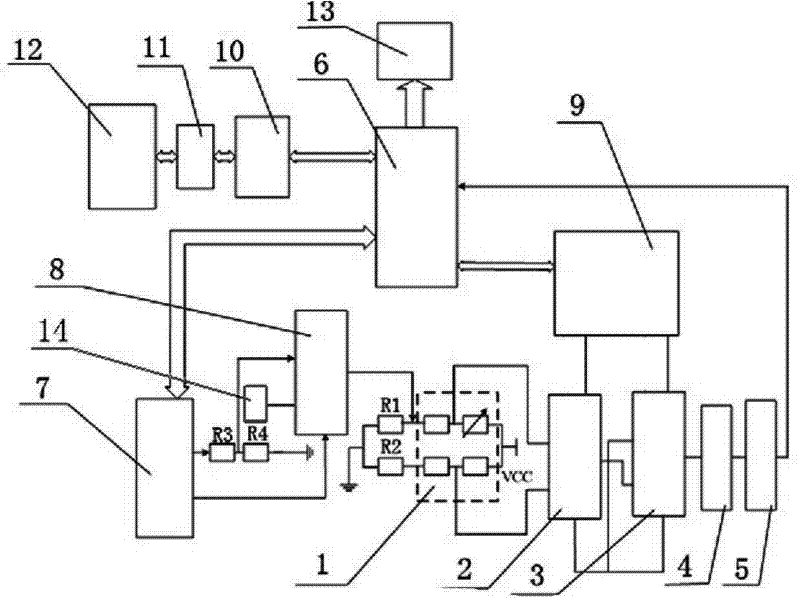

[0016]A microcantilever piezoresistive bridge sensor detector, comprising a microcantilever piezoresistive bridge sensor 1, a first differential amplifier 2, a filter 4, a voltage follower 5, a single-chip microcomputer 6, a computer 12, and an LCD display 13; The two output ends of the internal bridge of the micro-cantilever piezoresistive bridge sensor 1 are respectively connected to the non-inverting input end and the inverting input end of the first differential amplifier 2, and the output end of the first differential amplifier 2 is connected to the input end of the filter 4 connected; the output end of the filter 4 is connected with the input end of the voltage follower 5; the output end of the voltage follower 5 is connected with the analog-to-digital signal acquisition end of the single-chip microcomputer 6, and the serial port of the single-chip microcomputer 6 is connected with the computer 12, and the single-chip microcomputer 6 The display interface end of the digit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com