Gasification furnace with tar catalytic cracking structure

A technology of catalytic cracking and gasification furnace, which is applied in the field of gasification furnace, can solve the problem of tar and other problems, and achieve the effect of wide application range and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

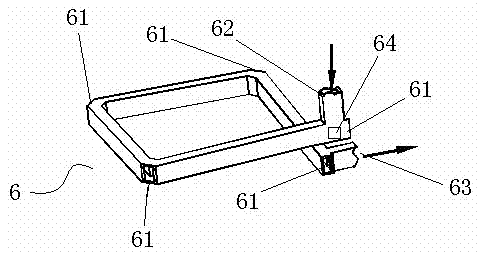

[0026] Such as figure 1 As shown, the gasifier with tar catalytic cracking structure in this embodiment includes a furnace body 1, and the furnace body 1 includes a feed inlet 2, an ash door 3 and a gas outlet 4, and the gas outlet 4 passes through a filter 5 and a multi-section tubular structure The cracker 6 communicates with each other. The cracker 6 is arranged in the body of furnace and has a part exposed inside the body of furnace. The part of the cracker 6 exposed inside the body of furnace is flush with the body of furnace. The filter 5 is a box structure, and partitions are arranged inside to form a "U"-shaped channel inside the box, which can not only block the particulate impurities in the gas, but also prevent tar from accumulating in the filter.

[0027] Such as figure 2 , 3 As shown, the cracker 6 is surrounded and arranged in the peripheral wall of the furnace body in the shape of a square frame. Inlet 64, the other end is provided with the second gas outle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com