Polyethylene material with high flame resistance

A technology of high-density polyethylene and polyethylene, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., to achieve the effects of low gas corrosion, good compatibility, and low smoke emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

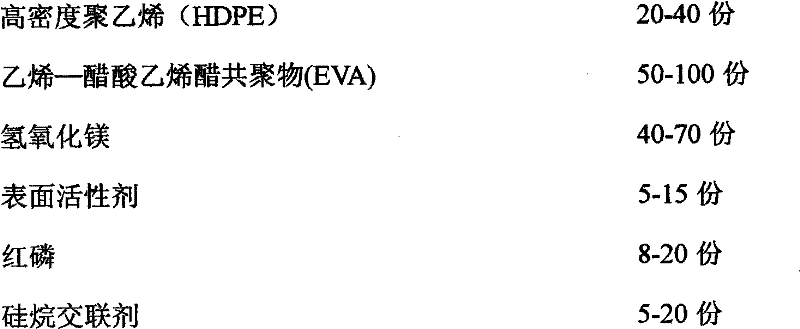

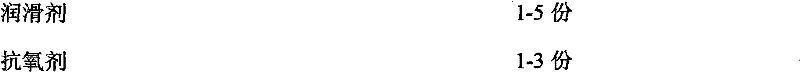

Image

Examples

Embodiment 1

[0019]

[0020]

[0021] High-density polyethylene, ethylene-vinyl acetate copolymer and Mg(OH) 2 , red phosphorus and surfactant are mixed together, add silane crosslinking agent and mix well. Lubricants, antioxidants and dispersants are added to the blended material, extruded into extruder at 120°C to 250°C for granulation, and dried to obtain.

Embodiment 2

[0023]

[0024] High-density polyethylene, ethylene-vinyl acetate copolymer and Mg(OH) 2 , red phosphorus and surfactant are mixed together, add silane crosslinking agent and mix well. Lubricants, antioxidants and dispersants are added to the blended material, extruded into extruder at 120°C to 250°C for granulation, and dried to obtain.

Embodiment 3

[0026]

[0027]

[0028] High-density polyethylene, ethylene-vinyl acetate copolymer and Mg(OH) 2 , red phosphorus and surfactant are mixed together, add silane crosslinking agent and mix well. Lubricants, antioxidants and dispersants are added to the blended material, extruded into extruder at 120°C to 250°C for granulation, and dried to obtain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com