Manufacturing method of SU-8 photoresist micro-force sensor

A micro force sensor, SU-8 technology, applied in the field of micro sensors, can solve the problems of high cost, long production process cycle, and difficult control of silicon doping concentration, etc., and achieve low processing cost, good biocompatibility, small elastic mode volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

[0023] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

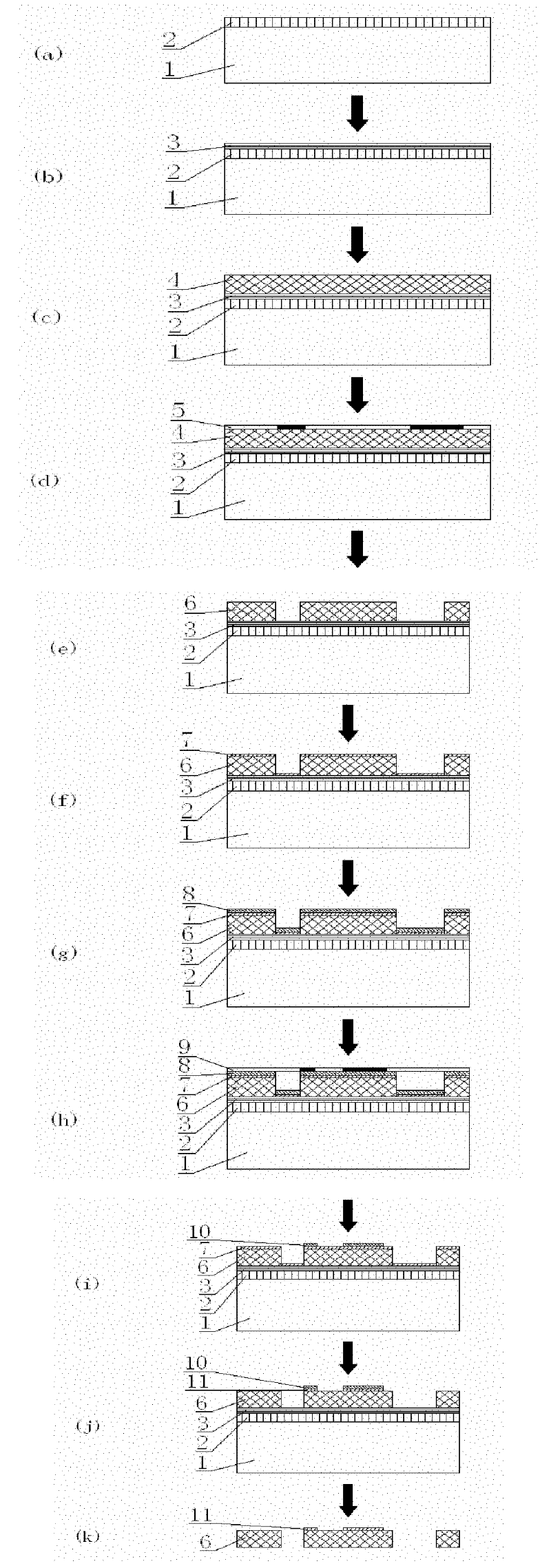

[0024] Such as figure 1 As shown in (a), after the silicon wafer 1 is cleaned by a standard cleaning solution, it is placed in an oxidation furnace to raise the temperature, and dry oxygen and wet oxygen are introduced in a certain order, so that a layer of dense silicon dioxide is formed on the surface of the silicon wafer. Layer 2, as the substrate. Such as figure 1 As shown in (b), a layer of Omnicoat adhesive layer 3 is spin-coated. By controlling the speed and time of the glue spinner, the thickness reaches about 1um, and then placed on a hot plate at 120°C for 30 minutes. Such as figure 1 As shown in (c), spin-coat a layer of SU-8 adhesive layer 4, by controlling the speed and time of the glue spinner, make its thickness reach about 25um, after standing for a period of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com