Halogen-free lead-free tin wire

A technology of lead-free solder and solder wire, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve problems such as poor wetting and poor welding, and achieve the effect of full solder joints and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

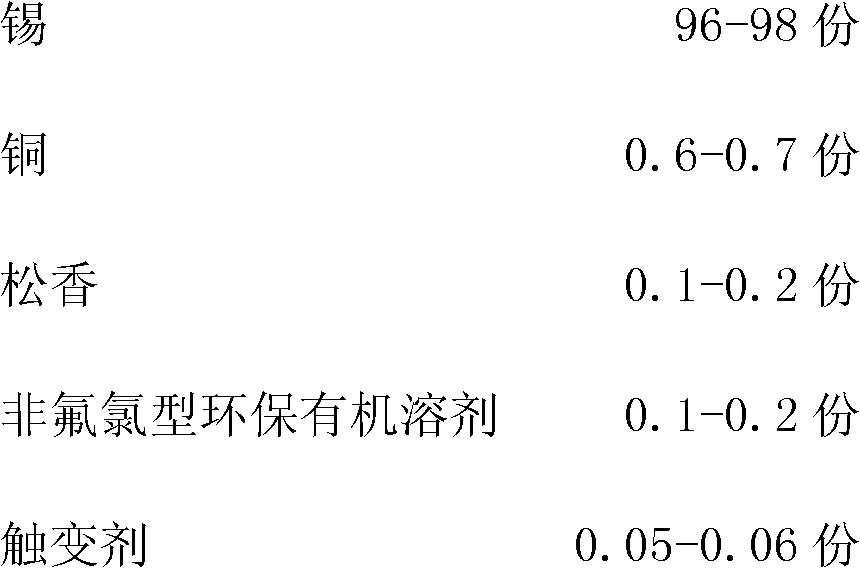

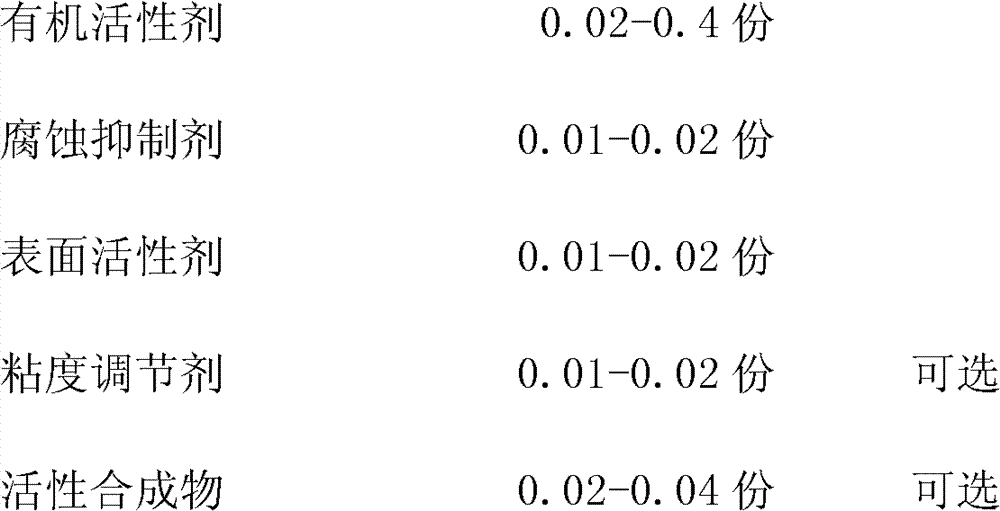

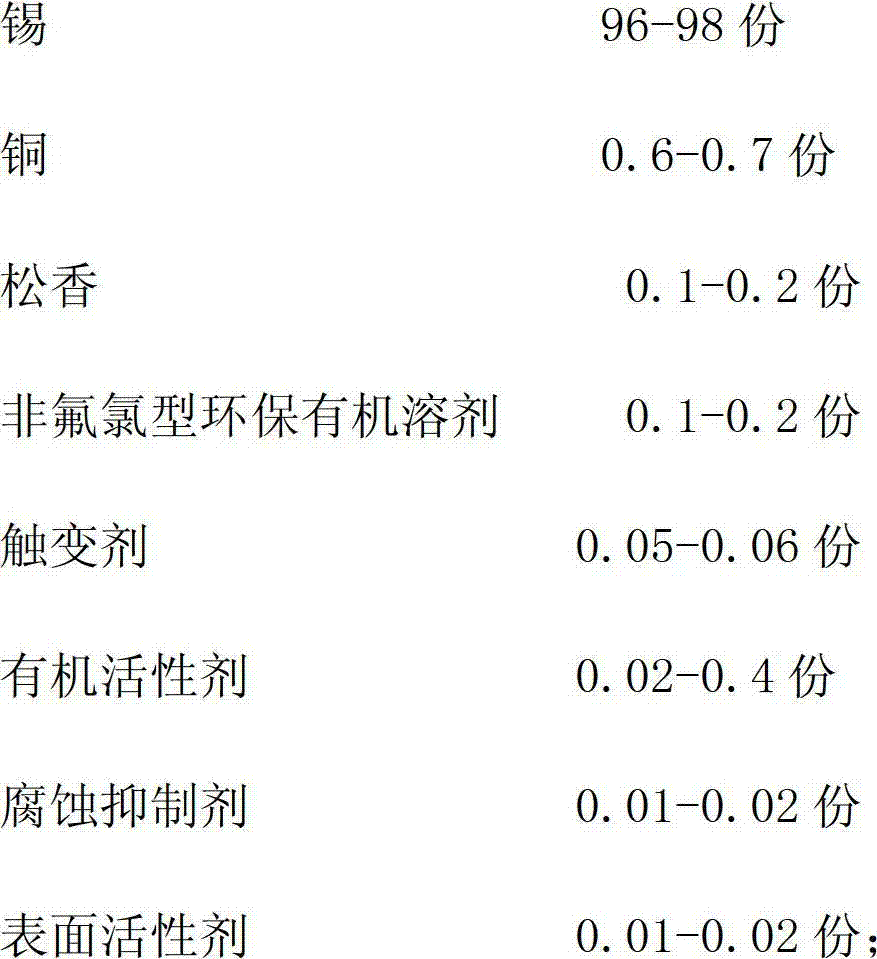

Method used

Image

Examples

Embodiment 1

[0029] The components in Example 1 per unit mass are: 96 parts of tin; 0.7 part of copper; 0.2 part of rosin; 0.1 part of diethylene glycol monobutyl ether; 0.05 part of hydrogenated castor oil; 0.01 part of nitrogen azole; 0.02 part of polyethylene glycol octylphenyl ether; 0.01 part of viscosity modifier, 0.025 part of active compound.

[0030] During production, tin and copper materials are first melted, mixed, and stirred evenly, and then poured into blocks, and the blocks should be convenient for subsequent drawing operations.

[0031] When making flux, first melt the rosin, and then add: diethylene glycol monobutyl ether, hydrogenated castor oil, glutaric acid, benzotriazole, polyethylene glycol octylphenyl ether, viscosity modifier, active compound. After fully stirring evenly, flux is obtained.

[0032] When drawing the above bulk solder, the flux is injected into the hollow tin wire to form the solder wire of the present invention.

[0033] When this embodiment is ...

Embodiment 2

[0035] 0.6 parts of copper; 0.2 parts of rosin; 0.2 parts of ethylene glycol propyl ether; 0.06 parts of hydrogenated castor oil; 0.4 parts of ethylenediamine; 0.02 parts; 0.01 parts of polyethylene glycol octyl phenyl ether; 0.02 parts of viscosity modifier, 0.04 parts of active compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com