Diode chip and processing technology thereof

A processing technology and diode technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve problems such as poor withstand voltage, chip creepage, easy discharge, etc., to improve diode withstand voltage and enhance device stability , Improve the effect of pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

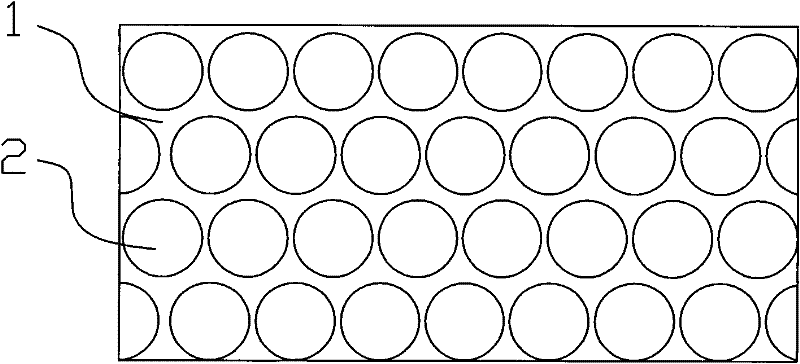

[0021] Diode chip of the present invention such as figure 1 , 2 As shown: the edge of the chip 2 is provided with a circle of glass protective layer 3, and the horizontal projection of the chip 2 is a closed shape without corners; the longitudinal section of the chip 2 is convex, and the upper part of the side is concave arc-shaped, The lower part is a straight side; the side is provided with a circle of semi-insulating polysilicon film (SIPOS film) 4; the glass protective layer 3 covers 70-95% of the upper part of the semi-insulating polysilicon film 4. An exposed section 5 is kept to prevent a gold layer from adhering to it when steaming gold.

[0022] Process of the present invention such as figure 1 , 2 Shown: Include the following steps:

[0023] 1), the engraving of wafer 1 split pattern; using a mask plate, and then processing grooves on the wafer by coating photoresist, soft baking, exposure, development, fixing and hard baking, so that the chips between the groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com