Passive residual heat removal system under accident of boiling-water reactor based on characteristics of nanometer fluid

A passive waste heat, nano-fluid technology, applied in the direction of reactor, nuclear power generation, reduction of greenhouse gases, etc., can solve the problems of heat transfer capacity of heat transfer medium and system power limitation, and achieve reliable performance, efficient heat removal, and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

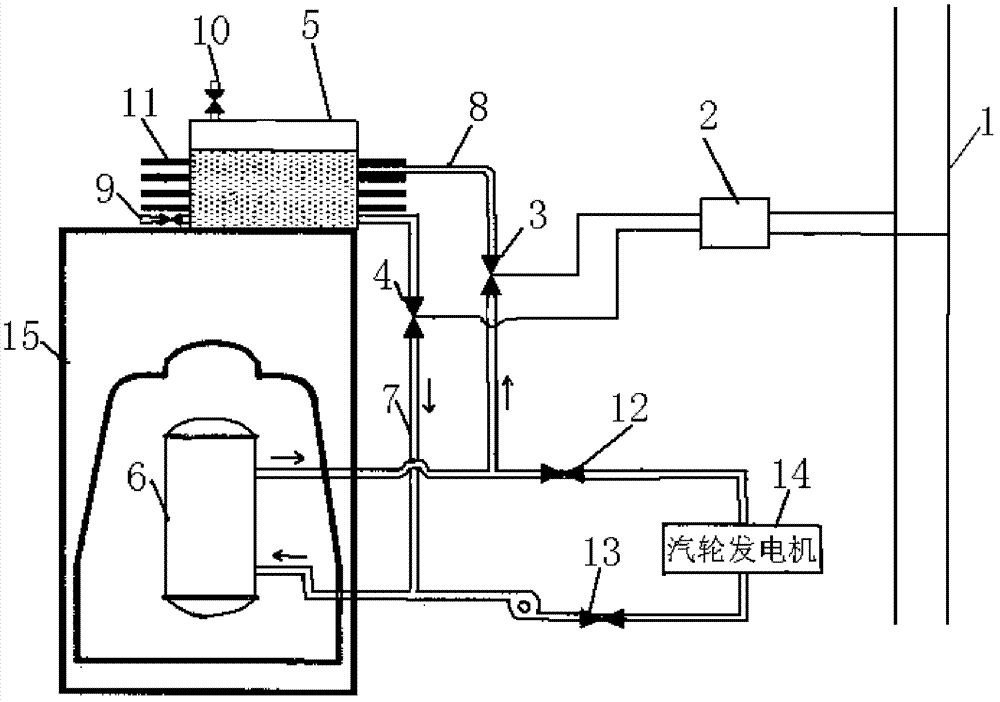

[0010] The invention provides a boiling water reactor passive residual heat derivation system based on the characteristics of nanometer fluid. Below in conjunction with accompanying drawing, concrete structure, working process of the present invention will be further described. figure 1 In the cooling system, a water tank 5 is installed on the top of the reactor containment 15, and the water tank 5 is respectively connected with the inlet pipe 7 and the outlet pipe 8 of the reactor core 6 pressure vessel through the second three-way valve 4 and the first three-way valve 3, The second three-way valve 4 and the first three-way valve 3 are connected to the factory power supply 1 through the valve controller 2; wherein the inlet pipe 7 and the outlet pipe 8 are connected to the steam valve through the second two-way valve 13, the first two-way valve 12 and the steam pipe respectively. The turbine generator 14 is connected; a safety valve 10 is set on the top of the water tank 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com