Handheld electric angle grinder

A technology for electric angle grinding machines, applied in grinding machines, portable grinding machines, grinding/polishing equipment, etc., which can solve problems affecting the operation reliability of the brushed motor 3' and the wear and tear of the commutator 31', so as to improve the operation More reliable performance and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

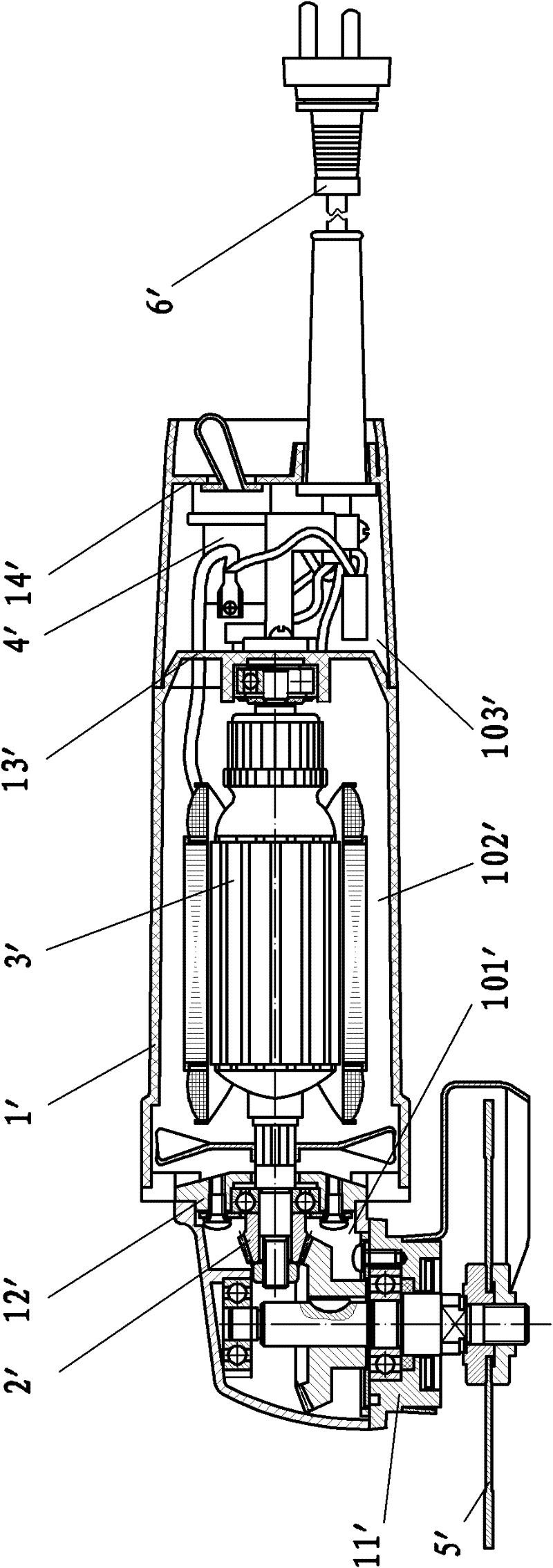

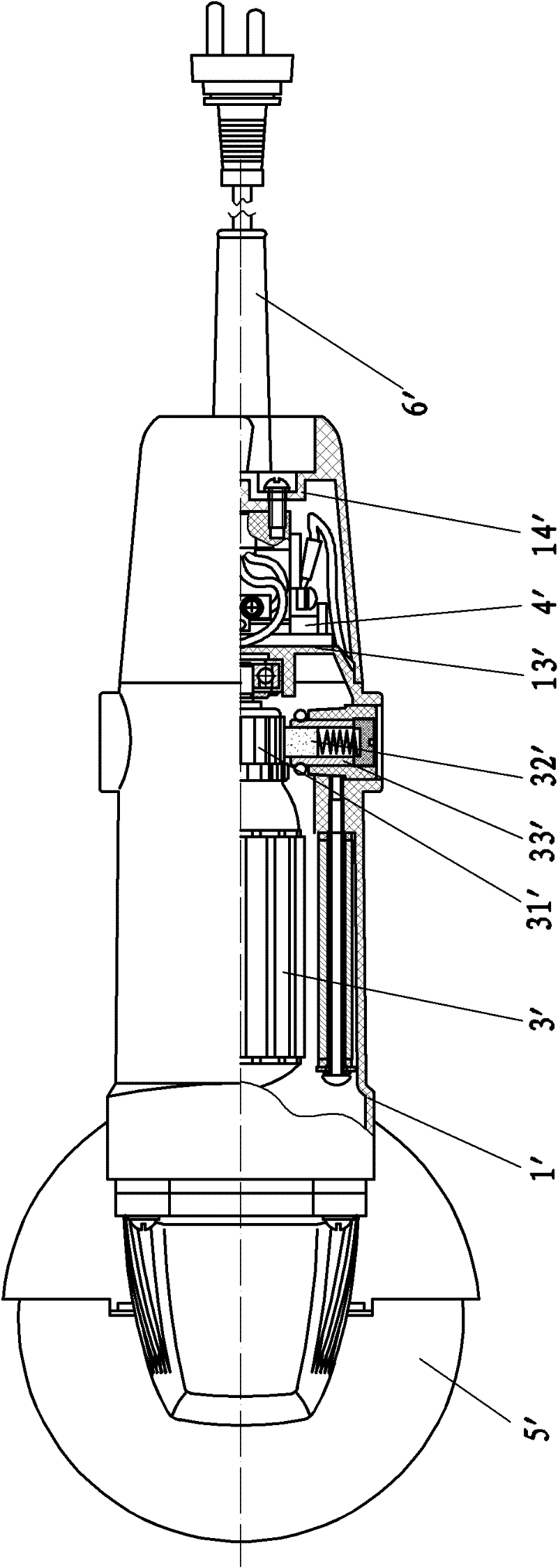

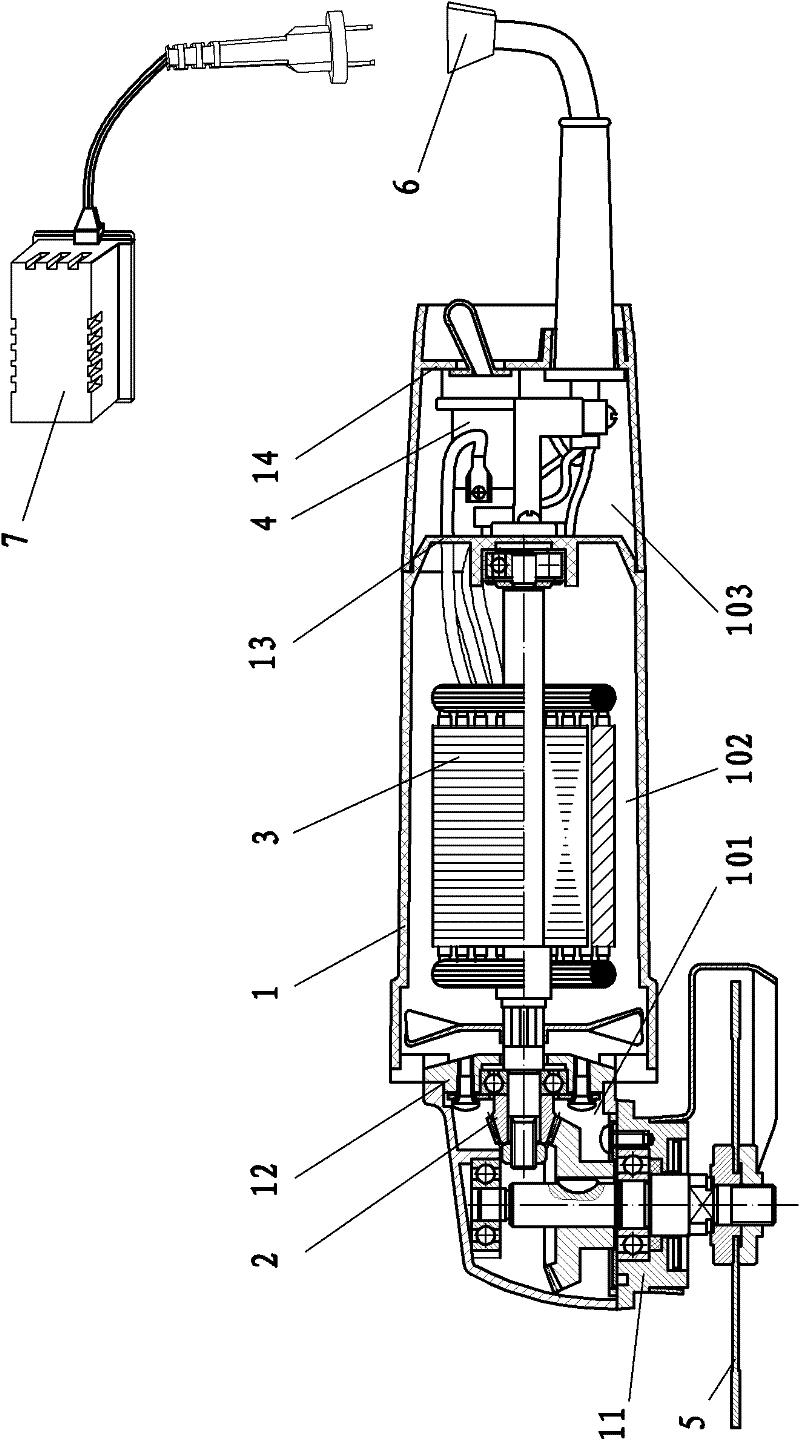

[0045] Such as Figure 3-4 As shown, the handheld electric angle grinder of the present invention includes a stator case 1 , a transmission assembly 2 , a three-phase asynchronous motor 3 , a control circuit 4 , a grinding wheel 5 , a power interface 6 and an electronic control unit 7 .

[0046] The stator case 1 is divided into a transmission chamber 101, a motor chamber 102 and a circuit chamber 103 through the front cover 11, the middle cover 12, the bearing chamber 13 and the rear cover 14 in sequence from front to back; the transmission assembly 2 is arranged in the transmission chamber 101, The three-phase asynchronous motor 3 is arranged in the motor chamber 102 , the control circuit 4 of the three-phase asynchronous motor 3 is arranged in the circuit chamber 103 , and the power interface 6 is arranged on the rear cover 14 . The transmission assembly 2 mainly includes a pinion 22 , an output shaft 23 and a bull gear 25 . The rotating shaft 31 of the three-phase asynchr...

Embodiment 2

[0056] The main difference between this embodiment and Embodiment 1 lies in the location of the electronic control unit. In this embodiment, the electronic control unit is located in the stator housing, and the electronic control unit is electrically connected to the control circuit of the high-frequency motor through a corresponding port.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com