Multielement rare-earth silver solder

A silver solder and multi-component technology, which is applied in the direction of welding/cutting media/materials, welding media, metal processing equipment, etc., can solve the problems of excessive silver consumption, performance that cannot meet the requirements, and high cost, and achieve excellent process performance, The effect of excellent mechanical properties and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The specific parameters in each embodiment refer to Table 1-Table 4, Table 1 is the relevant data table of Embodiment 1-Example 6 of the present invention, Table 2 is the relevant data table of Embodiment 7-Example 12 of the present invention, and Table 3 is this Invention embodiment 13-embodiment 18 related data tables, Table 4 is the data table related to embodiment 19-embodiment 24 of the present invention, and the details of each table are as follows.

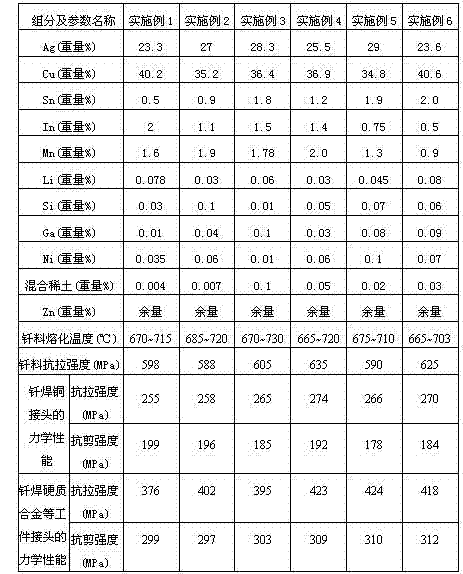

[0020] Table 1 Example 1-Example 6 related data table

[0021]

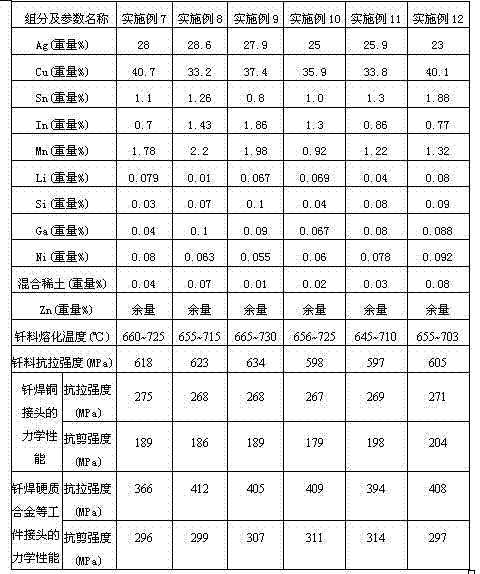

[0022] Table 2 Embodiment 7-Example 12 related data table

[0023]

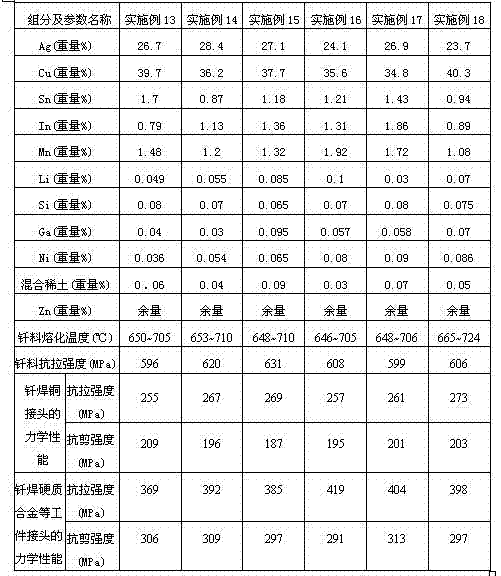

[0024] Table 3 Example 13-Example 18 related data table

[0025]

[0026] Table 4 Relevant data table of embodiment 19-embodiment 24

[0027]

[0028] The formula design of the invention is reasonable, the production cost is low, and the cost performance is high. When welding metal materials such as copper and copper alloy, hard alloy, carbon steel, stainless steel, and nic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com