Coating for lost mould cast steel and manufacture method thereof

A manufacturing method and technology of lost foam, applied in the direction of manufacturing tools, casting molding equipment, coatings, etc., can solve the problems of poor suspension stability of coatings, high casting rejection rate, low purity of zircon powder, etc., and achieve good thermal stability, Good anti-sand sticking effect, better cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

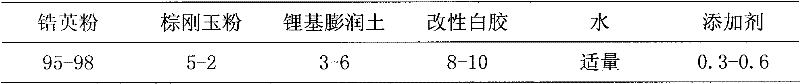

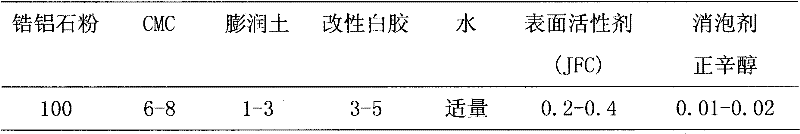

[0027] The invention discloses a coating for lost foam cast steel. The coating uses zirconite powder as a refractory material, CMC and bentonite as a suspending agent, modified white glue as a binder, and an appropriate amount of water as a material coating carrier liquid and additives.

[0028] Further preferably, the mass ratio of the coating is: 100 parts of zirconite powder, 6-8 parts of CMC, 1-3 parts of organic bentonite, 3-5 parts of modified white glue, and additives.

[0029] Further preferably, the additives are surfactant JFC and defoamer n-octanol.

[0030] Further preferably, the mass ratio of the additives is: 0.2-0.4 part of surfactant JFC, and 0.01-0.02 part of n-octanol as antifoaming agent.

[0031] The distribution ratio of each component of a coating for lost foam casting steel described in the present invention is shown in Table 2.

[0032] Table 2 The ratio of each component of the coating (mass: %)

[0033]

[0034] The preparation of the paint is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com