Catalyst containing nickel-iron-manganese compound oxide for processing industrial waste gas and preparation method thereof

A technology of composite oxides and industrial waste gas, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, molecular sieve catalysts, etc. and other problems, to achieve the effect of easy expansion and reproduction, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

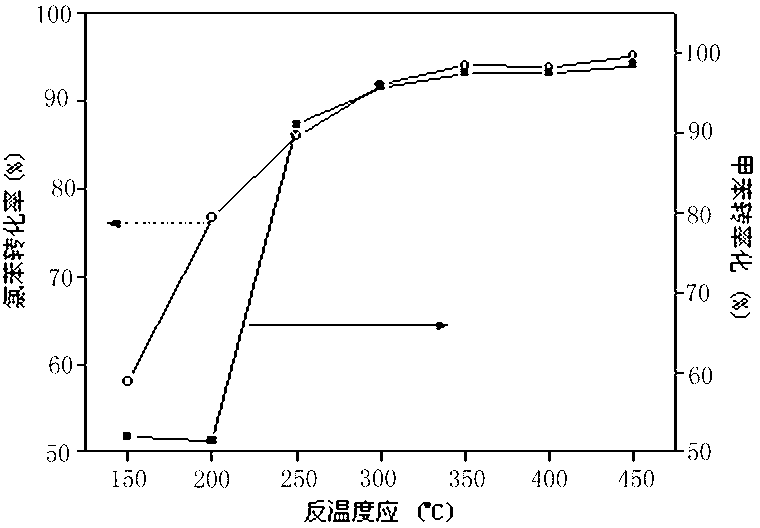

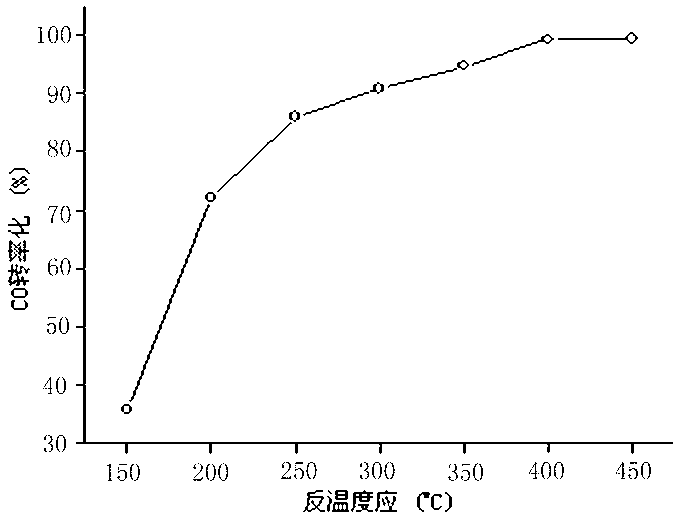

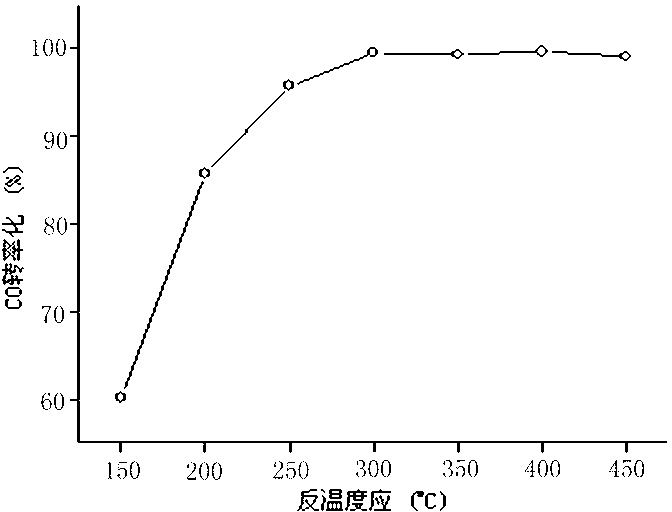

Image

Examples

Embodiment 1

[0036] (1) Preparation of self-made cordierite carrier

[0037] Take 30g of silica, 40g of alumina and 30g of magnesia and mix evenly. The mixture is roasted at 1300°C, and the holding time is controlled at 6h; the self-made carrier is modified with oxalic acid solution with a mass concentration of 5%, boiled on an electric furnace and kept for 2h. The drying temperature was 80°C, and the drying time was 2 h; the calcination temperature was 400°C, and the calcination time was 6 h, and the self-made cordierite carrier was obtained;

[0038] (2) Modification of self-made cordierite carrier

[0039] Take the above-mentioned 50g carrier and impregnate it in alumina sol for 4 hours, dry it at 80°C for 2 hours, and then roast it at 500°C for 4 hours to obtain a modified cordierite carrier with a mass percentage of alumina of 1%;

[0040] (3) Preparation of nickel-iron-manganese composite oxide catalyst

[0041] Take 50 g of the self-made carrier sample in step (2) and impregna...

Embodiment 2

[0045] (1) Preparation of self-made cordierite carrier

[0046] Take 35g of silica, 40g of alumina and 25g of magnesia and mix evenly. The mixture is roasted at 1400°C, and the holding time is controlled at 6h; the self-made carrier is modified by nitric acid solution with a mass concentration of 10%, boiled on an electric furnace and kept for 2h. The drying temperature was 80°C, and the drying time was 2 h; the calcination temperature was 400°C, and the calcination time was 6 h, and the self-made cordierite carrier was obtained;

[0047] (2) Modification of self-made cordierite carrier

[0048] Take the above-mentioned 50g carrier and impregnate it in silica sol for 4 hours, dry it at 80°C for 2 hours, and then roast it at 500°C for 4 hours to obtain a modified cordierite carrier with a mass percentage of silicon oxide of 4%;

[0049] (3) Preparation of nickel-iron-manganese composite oxide catalyst

[0050] Take 50 g of the self-made carrier sample in step (2) and impr...

Embodiment 3

[0054] (1) Preparation of self-made cordierite carrier

[0055] Take 55g of silicon oxide, 20g of aluminum oxide and 25g of magnesium oxide and mix evenly. The mixture is roasted at 1400°C, and the holding time is controlled at 4h; the self-made carrier is modified with acetic acid solution with a mass concentration of 20%, boiled on an electric furnace and kept for 3h. The drying temperature was 120°C, and the drying time was 1 h; the calcination temperature was 600°C, and the calcination time was 4 h, and the self-made cordierite carrier was obtained;

[0056] (2) Modification of self-made cordierite carrier

[0057] Take the above-mentioned 50g carrier and impregnate it in silica sol for 6 hours, dry it at 120°C for 1 hour, and then roast it at 600°C for 2 hours to obtain a modified cordierite carrier with a mass percentage of silicon oxide of 10%;

[0058] (3) Preparation of nickel-iron-manganese composite oxide catalyst

[0059] Take 50 g of the self-made carrier sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com