Preparation method of nanoscale zirconium phosphate silver-carrying composite inorganic antimicrobial agent

A technology of silver-loaded zirconium phosphate and inorganic antibacterial agent, which is applied in the fields of botanical equipment and methods, biocides, disinfectants, etc., can solve the problems of increased sol agglomeration, difficulty in making ultrafine or nanoscale powders, etc. Achieve good antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

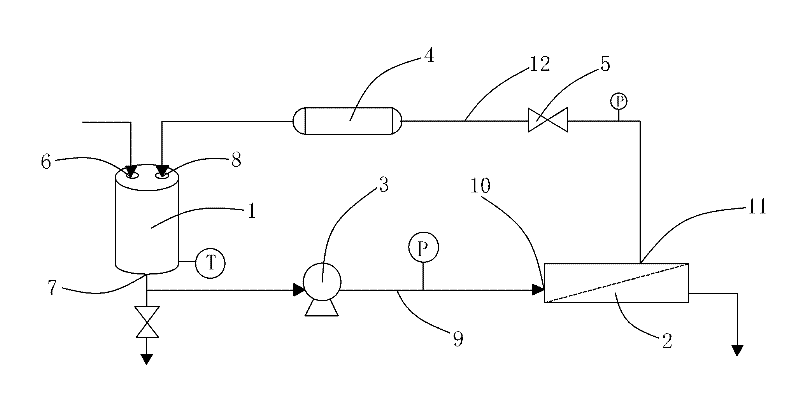

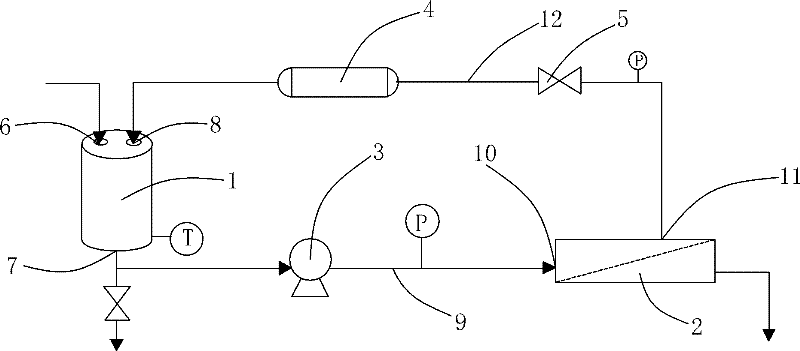

[0034] Take 500g zirconium oxychloride octahydrate (chemically pure), dissolve it with 2 liters of pure water, add 2g PEG (polyethylene glycol), 2g PVA (polyvinyl alcohol), and stir well. Get 285g ammonium dihydrogen phosphate (chemically pure) in addition, dissolve with 2 liters of pure water, put into the overhead tank, be mixed with solution. Slowly add ammonium dihydrogen phosphate solution dropwise to the zirconium oxychloride solution under high-speed stirring, and a precipitation reaction occurs at room temperature. After the reaction is completed, the product enters the ultrafiltration membrane system for desalination operation, such as figure 1 As shown in , the zirconium phosphate feed liquid ultrafiltration membrane impurity removal system mainly includes a material tank 1 , an ultrafiltration membrane system 2 and a heat exchanger 4 . The feed tank 1 has a water inlet 6, a feed inlet 8 and a discharge outlet 7, the water inlet 6 communicates with a continuous wate...

Embodiment 2

[0045] Take 100kg zirconium oxychloride octahydrate (chemically pure) in a 1000L enamel container, dissolve it with 200 liters of pure water, add 200g PEG, 200g PVA, and stir well. Get 57kg ammonium dihydrogen phosphate (chemically pure) in addition, dissolve with 200 liters of pure water, put into the overhead tank, be mixed with solution. Slowly add ammonium dihydrogen phosphate solution dropwise to the enamel container under high-speed stirring, and a precipitation reaction occurs at room temperature. After the reaction is completed, the product enters the ultrafiltration membrane system for desalination operation. After running for 5 to 6 hours, use silver nitrate solution to check whether the filtrate contains chloride ions.

[0046] After chlorine ions are completely removed, stop the operation of the ultrafiltration membrane system, collect the precipitate, pour it into a 300L enamel reactor, add pure water, add 100g of PVA and 100g of CMC surfactant, stir until it is h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com