Organic compound steam generator and apparatus for producing organic thin film

A steam generating device and organic compound technology, which can be used in lighting devices, vacuum evaporation coating, devices for coating liquid on surfaces, etc., and can solve problems such as backflow of organic material vapor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

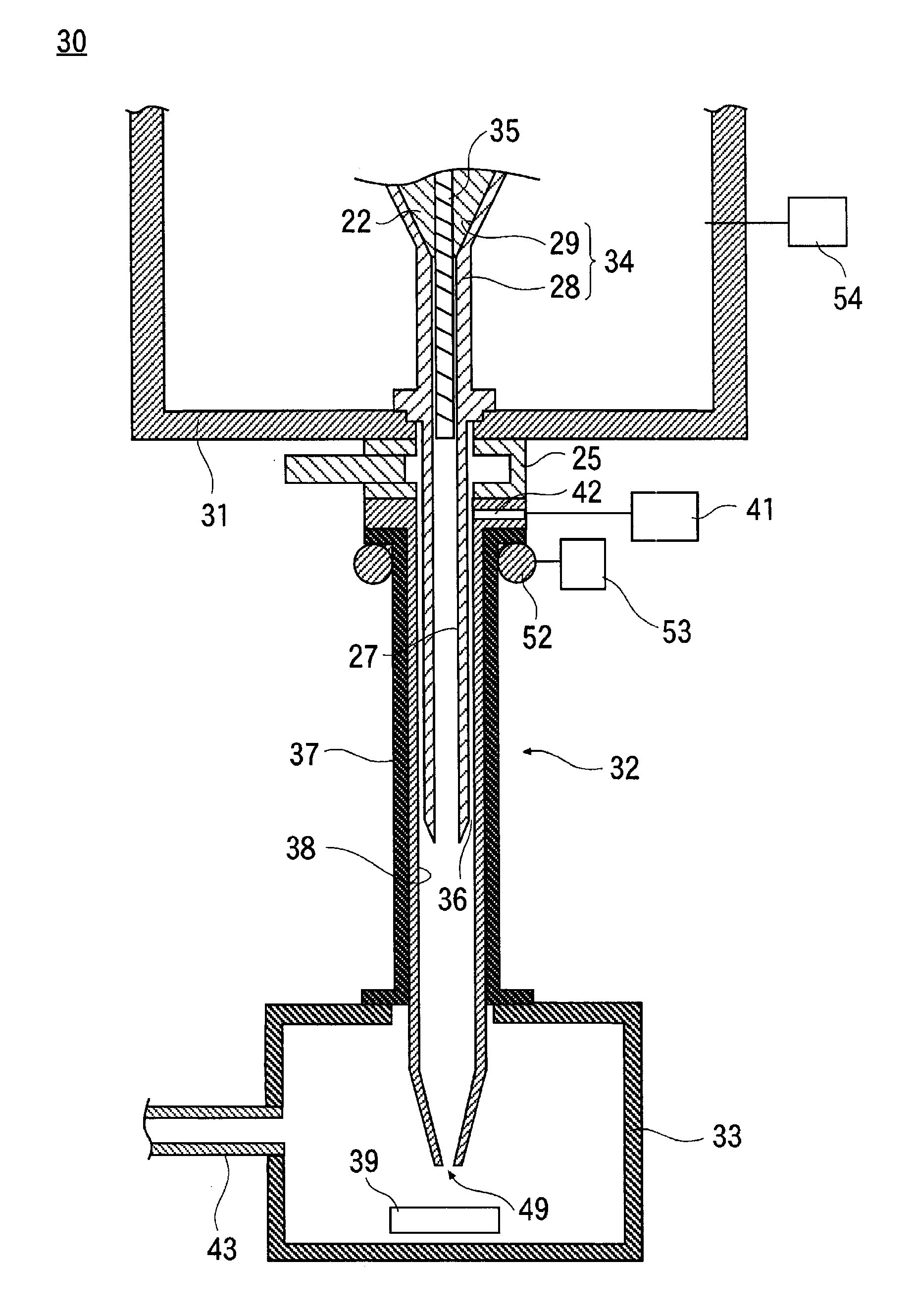

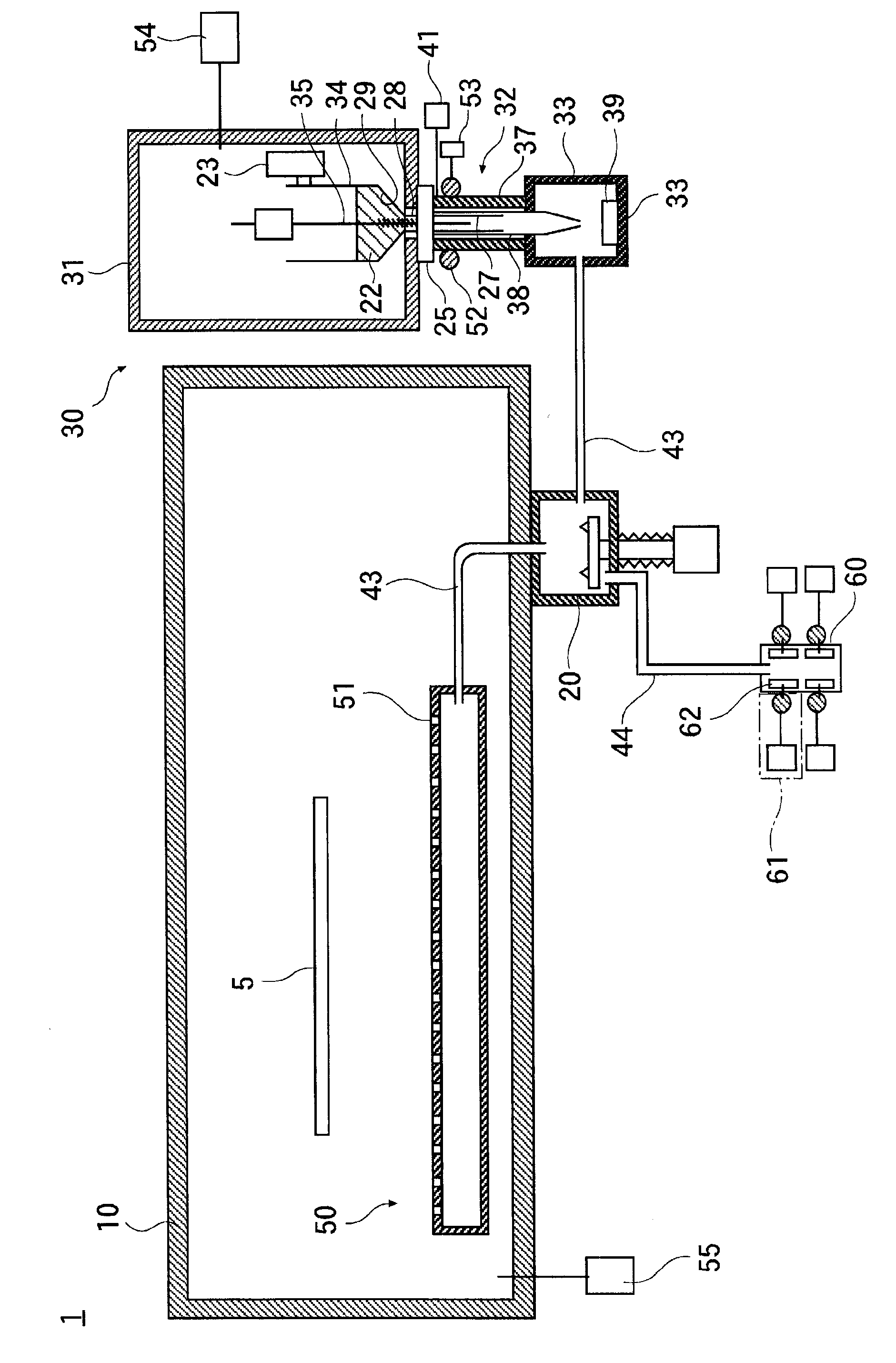

[0057] figure 1 Reference numeral 1 is an organic thin film production device (vapor deposition device) according to an example of the present invention.

[0058] This organic thin film manufacturing apparatus 1 has a film forming tank 10 , a steam generating device 30 , and a steam releasing device 50 .

[0059] The steam releasing device 50 is arranged inside the film forming tank 10 . The steam generator 30 is connected to the steam release device 50 via the connection valve 20 , and when the connection valve 20 is turned on, the steam of the organic compound generated in the steam generator 30 is supplied to the steam release device 50 . The organic compound vapor supplied to the vapor releasing device 50 is released from a plurality of releasing ports 51 of the vapor releasing device 50 into the film forming tank 10 in a vacuum environment.

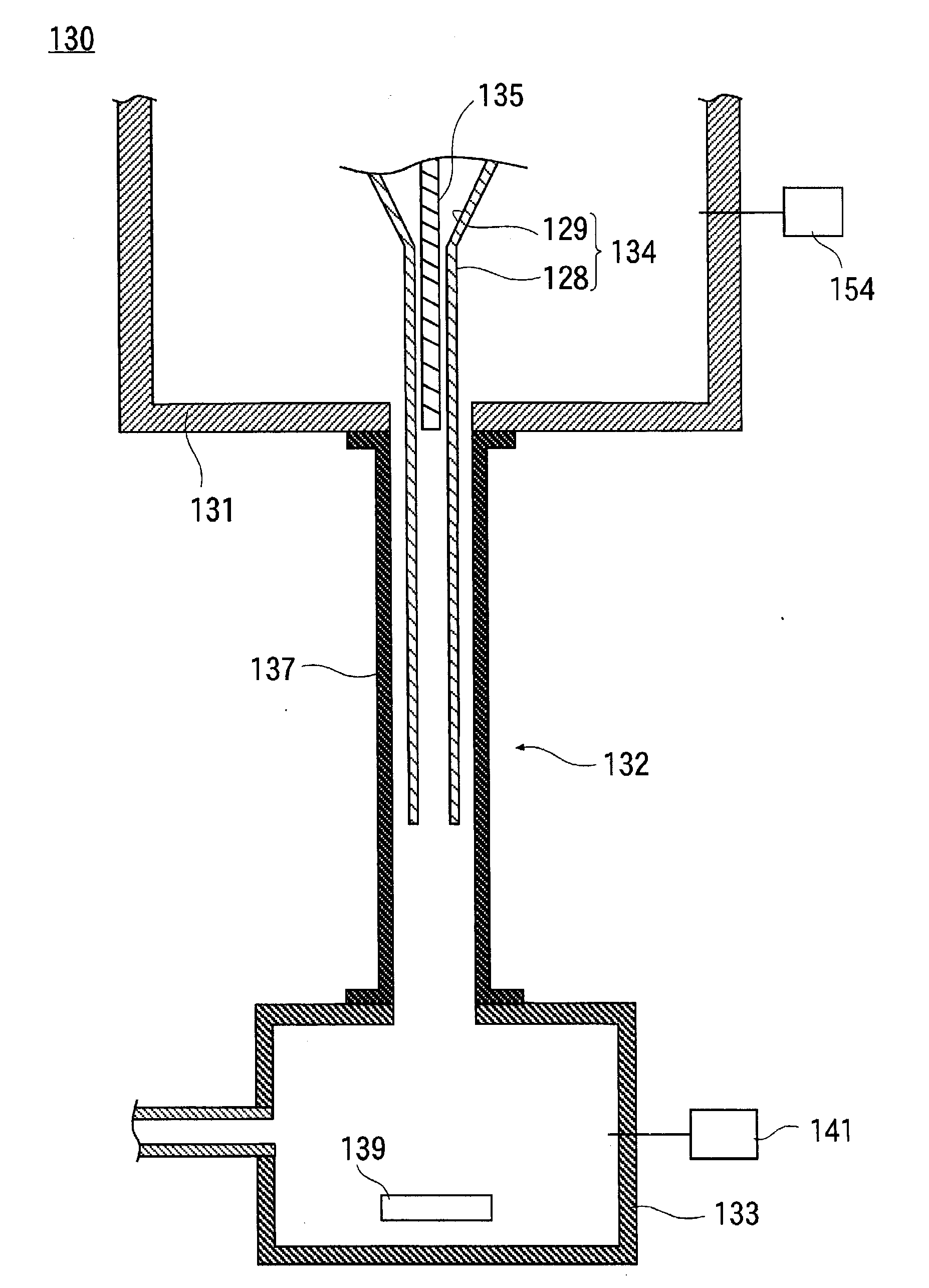

[0060] figure 2The shown steam generator 30 is an example of the present invention, and has a storage tank 31 , a transport de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com