Method for inhibiting porous low dielectric constant medium from absorbing water vapor

A low dielectric constant, dielectric technology, applied in the field of microelectronics, can solve the problems of increasing the interconnection delay, increasing the effective dielectric constant of the medium in the interconnection structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

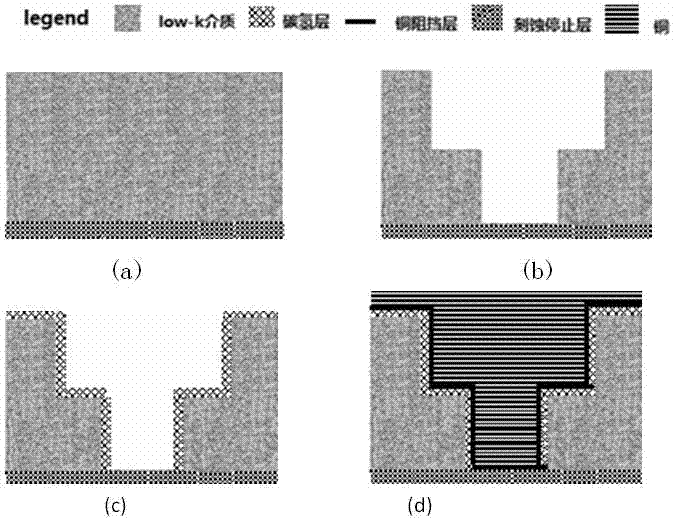

Method used

Image

Examples

Embodiment 1

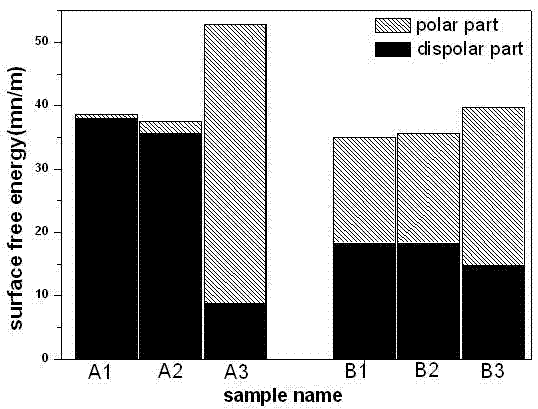

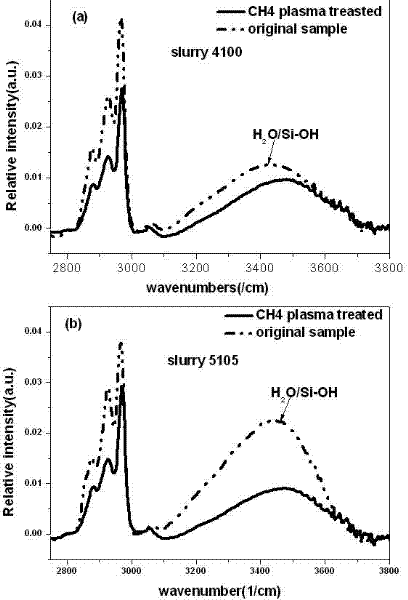

[0020] After the porous low-K dielectric is etched to form a pattern, a certain proportion of methane and argon is filled in the CVD chamber. In this example, the ratio of CH4 / Ar gas flow is 30sccm / 100sccm. K medium for processing. The various condition parameters in this example are: the air pressure is 0.3 Torr, the power is 160 watts, and the processing time is 30 seconds. After treatment, the surface and sidewalls of the porous low-K media are covered with a hydrocarbon layer. combine figure 2 The surface free energy spectrum of and image 3 Fourier Transform Infrared Spectroscopy (FTIR), it can be seen that after soaking in the two polishing solutions for 5 minutes, the water vapor in the porous low-k medium sample after methane plasma treatment is significantly less than that of the untreated porous low-k medium sample. From Figure 8 It can be seen that after methane plasma treatment, the dielectric constant of the porous low-K dielectric is almost the same as tha...

Embodiment 2

[0022] After the porous low-k dielectric is etched to form patterns, the CVD chamber is filled with a certain proportion of methane and helium, and the porous low-k dielectric is treated with methane and helium plasma. After treatment, the surface and side walls of the porous low-K medium will be covered with a layer of carbon layer, which can prevent the inhalation of water vapor in the subsequent process and improve the reliability of the application of the porous low-K medium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com