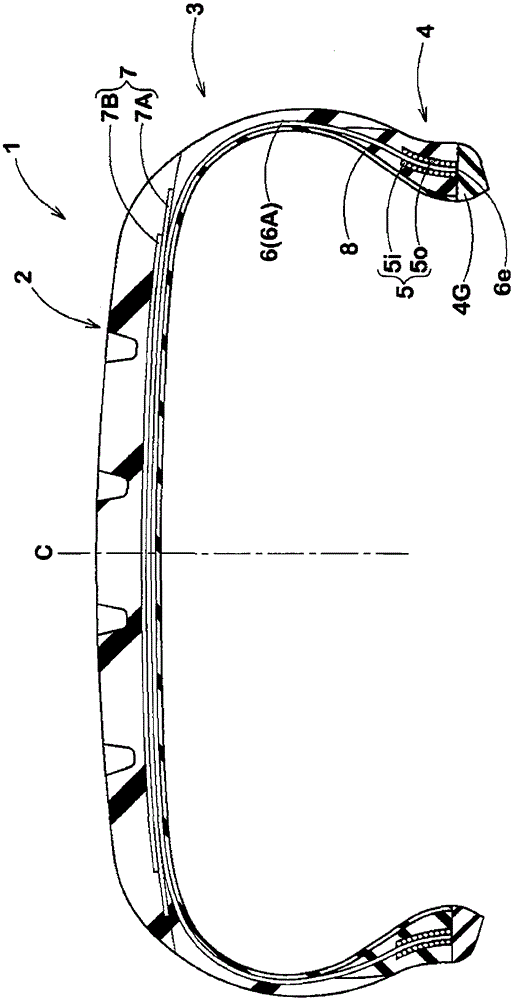

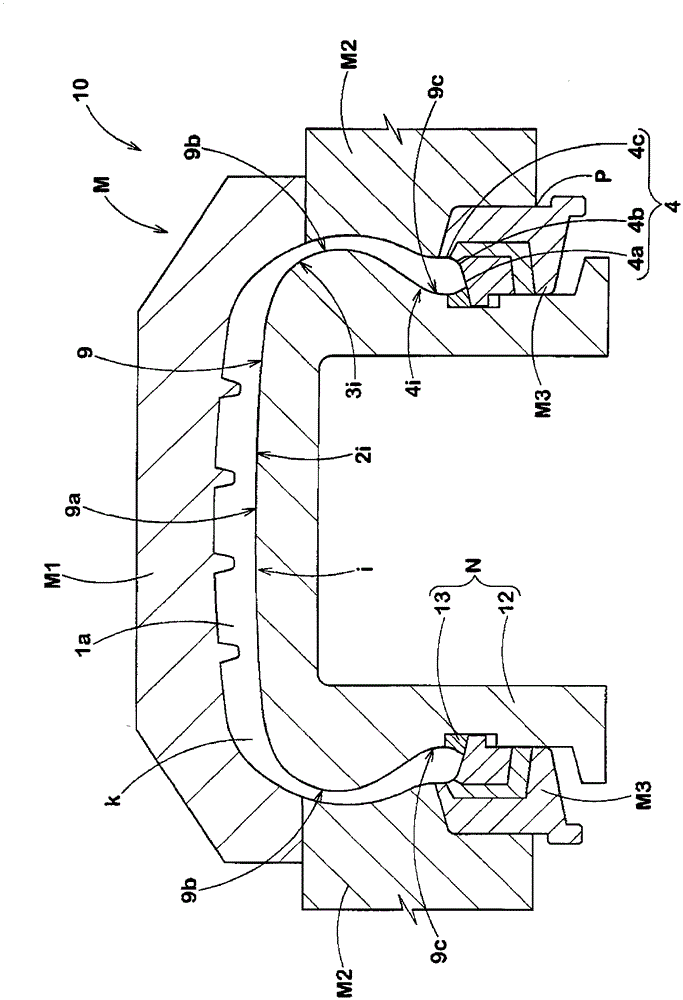

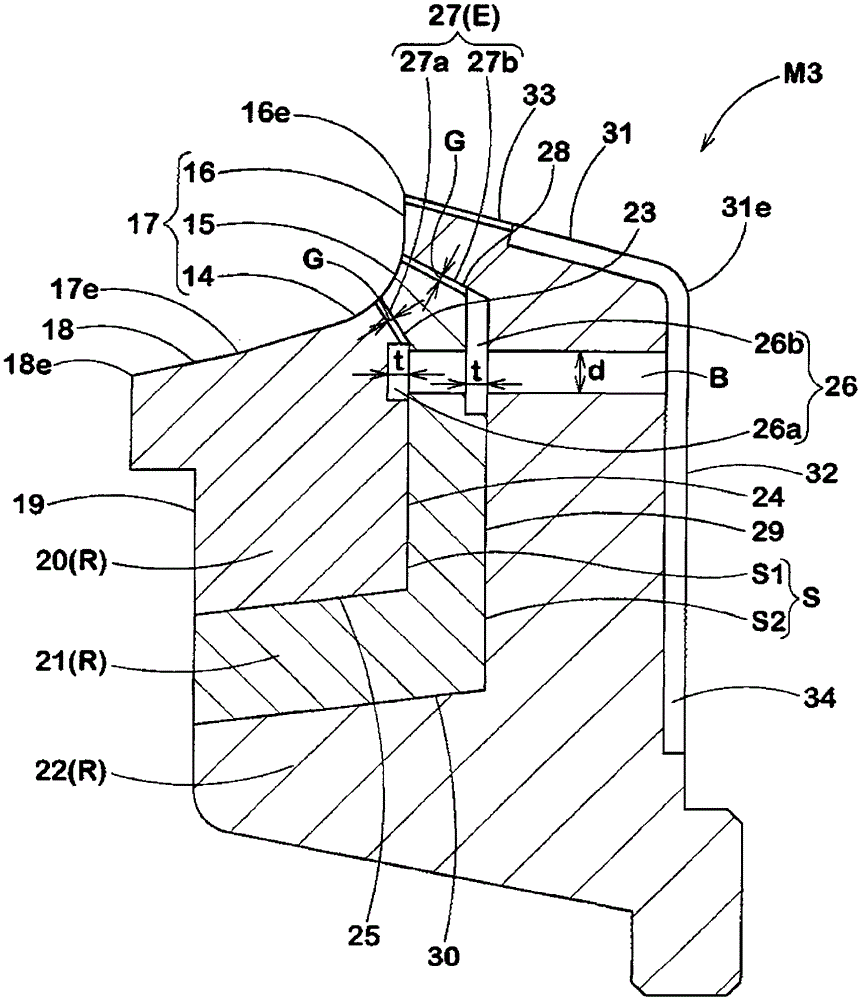

tire vulcanization mold

A technology for vulcanizing molds and tires, which is applied to tires, household appliances, and other household appliances. It can solve the problems of poor fitting, time-consuming, and difficult formation of tire heel forming surfaces, and achieves suppression of inhalation and reduction of formation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] In order to confirm the effect of the present invention, 100 pneumatic radial tires for passenger cars with a size of 215 / 45R17 were trial-produced according to the specifications in Table 1, and the appearance of the bead heel surface of the bead portion was investigated. Except for the parts described in the table, the rest are the same. The main common specifications are as follows.

[0063]

[0064] Arrangement number: 300 on the tire circumference

[0065]

[0066] The number of configurations: 12 configurations on the tire circumference

[0067] Circumferential angle θ1: 20 degrees

[0068] The aesthetic condition of the bead heel surface was judged in five stages using the following criteria by visual inspection and palpation by inspectors. The higher the value, the better.

[0069] 5: There is no covering or extruding glue, etc.

[0070] 4: Although there are some uncovered or extruded glue, etc., there is no need to repair and it is a tolerable level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com