Emulsified asphalt and preparation method thereof

A technology of emulsified asphalt and asphalt, which is applied to building components, building insulation materials, buildings, etc., can solve the problems of emulsion storage stability, poor adhesion of mixtures, and deterioration of asphalt adhesion, so as to avoid Freeze shrinkage cracking or freeze-thaw loosening, good cohesiveness, and strong cohesive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

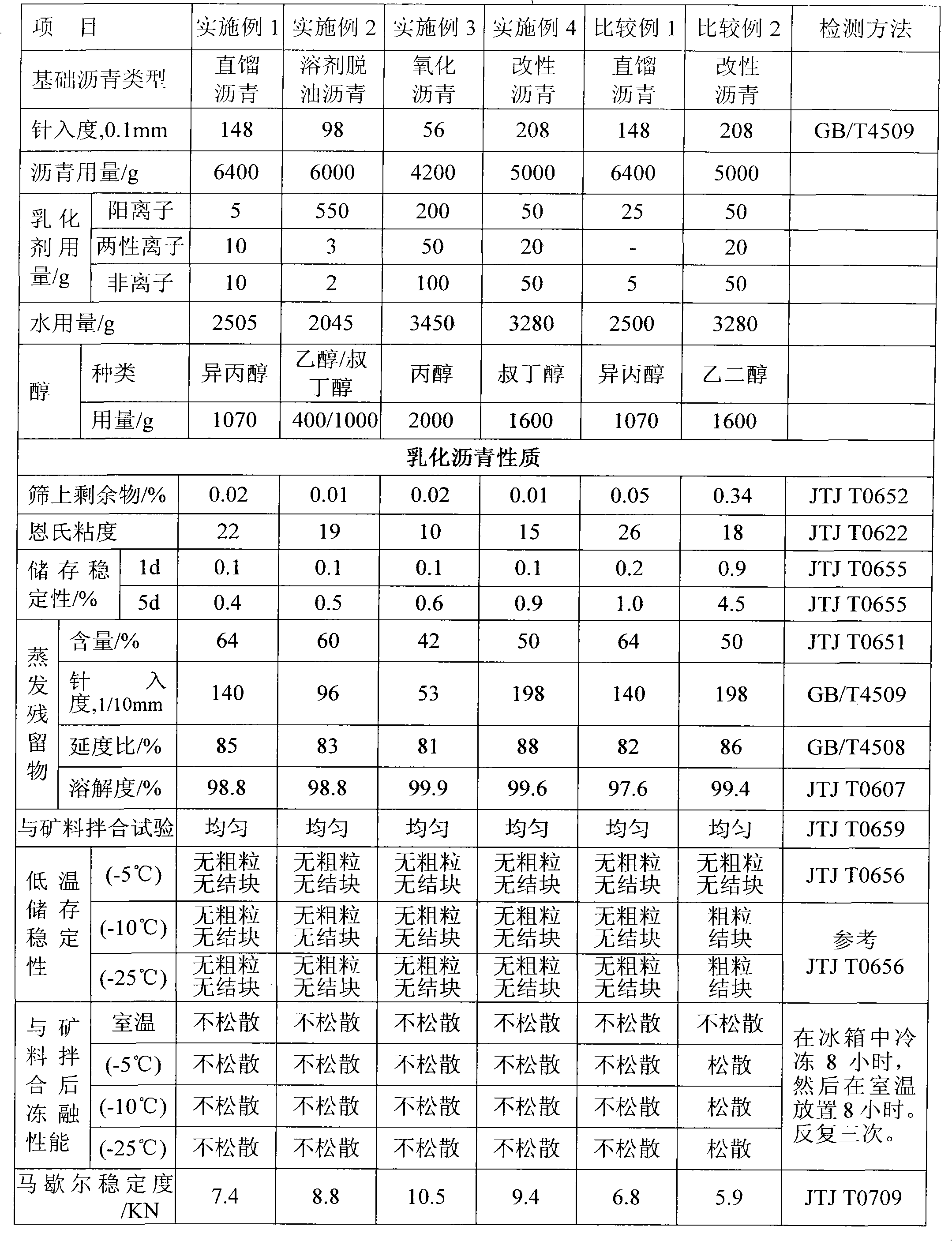

Examples

Embodiment 1

[0028] Take 6400g of Liaohe crude oil straight-run bitumen with a penetration of 1481 / 10mm, and heat it to 115°C for later use. Get cationic emulsifier cetyltrimethylammonium chloride 5g, zwitterionic emulsifier N-cocoyl-beta-alanine sodium 10g, nonionic emulsifier oleyl alcohol polyoxyethylene (20) ether 10g, dissolved in 2505g of water together, after the emulsifier is fully dissolved, then add 1070g of isopropanol, stir well, heat to 42°C, and prepare soap for later use. Then the soap liquid and asphalt are transported to the colloid mill respectively, after being uniformly dispersed and ground by the colloid mill, it becomes an oil-in-water emulsion, and then the temperature of the emulsion is lowered to below 60°C through the cooler, and the emulsion flows out from the outlet of the system to obtain the anti-corrosion emulsion. Freezing emulsified asphalt. The specific results are shown in Table 1.

Embodiment 2

[0030] Take 6000g of Oman crude oil solvent deoiled bitumen from Maoming Petrochemical Company with a penetration of 981 / 10mm, and heat it to 125°C for later use. Get cationic emulsifier octadecyltrimethylammonium chloride 550g, zwitterionic emulsifier N-lauryl-β-alanine 3g, nonionic emulsifier palmityl polyoxyethylene (20) ether 2g, Dissolve in 2045g of water. After the emulsifier is fully dissolved, add 400g of ethanol and 1000g of tert-butanol, stir well, heat to 50°C, and prepare soap for later use. Then the soap liquid and asphalt are transported to the colloid mill respectively, after being uniformly dispersed and ground by the colloid mill, it becomes an oil-in-water emulsion, and then the temperature of the emulsion is lowered to below 50°C by the cooler, and the emulsion flows out from the outlet of the system to obtain the anti-corrosion emulsion. Freezing emulsified asphalt. The specific results are shown in Table 1.

Embodiment 3

[0032] Take 4200g of Kuwait crude oil oxidized bitumen from Qilu Petrochemical Company with a penetration of 561 / 10mm, and heat it to 155°C for later use. Get 200g of cationic emulsifier octadecyltrimethylbenzyl ammonium chloride, 50g of zwitterionic emulsifier N-tallow-β-iminodipropionate disodium, nonionic emulsifier lauryl polyoxygen Dissolve 100g of ethylene (20) ether in 3450g of water. After the emulsifier is fully dissolved, add 2000g of propanol, stir well, heat to 55°C, and prepare soap for use. Then the soap liquid and asphalt are sent to the colloid mill respectively, after being evenly dispersed and ground by the colloid mill, it becomes an oil-in-water emulsion, and then the temperature of the emulsion is lowered to below 70°C by the cooler, and the emulsion flows out from the outlet of the system to obtain the anti-corrosion emulsion. Freezing emulsified asphalt. The specific results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com