Method for preparing 2-(7-methoxy-1-naphthyl) ethylamine industrially

A methoxy and naphthyl technology, applied in the field of preparation of 2-ethylamine, can solve the problems of difficult purification, unfavorable large-scale industrial production, high requirements for production equipment, etc., and achieves improved product yield, safety and simple post-processing , reducing the effect of post-processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

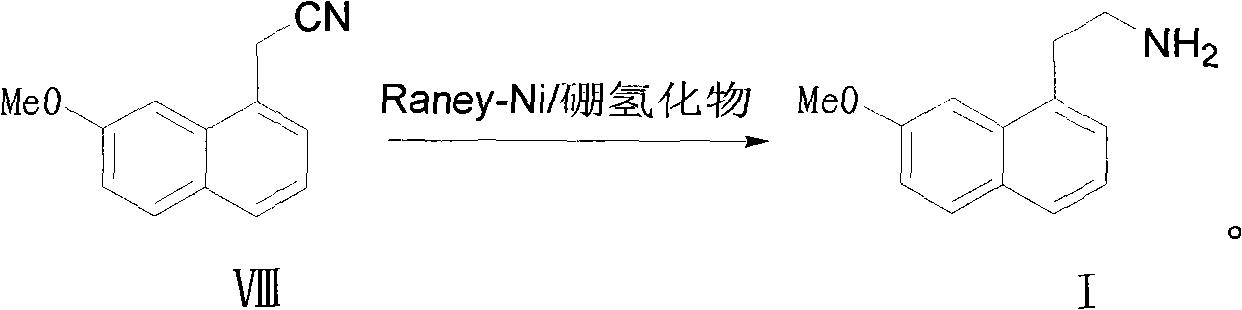

[0022] Dissolve compound VIII (1.97g) in ethanol (30ml), add Raney-Ni (0.5g) dissolved in ethanol, cool to 10 degrees, add potassium borohydride (0.54g) in batches, remove the ice bath, and react at room temperature After 23 hours, the substrate disappeared, the solvent was removed by concentration under reduced pressure, and ethyl acetate (30ml) was added for extraction; the organic phase was washed with acid, alkali, saturated brine, and concentrated to obtain the final product. Yield: 95%.

Embodiment 2

[0024] Dissolve compound VIII (9.85g) in methanol (150ml), add Raney-Ni (3g) dissolved in ethanol, cool to 10 degrees, add potassium borohydride (2.7g) in batches, remove the ice bath, and react at room temperature for 18 After hours, the substrate disappeared, the solvent was removed by concentration under reduced pressure, and ethyl acetate (150ml) was added for extraction; the organic phase was washed with acid, alkali, saturated brine, and concentrated to obtain the final product. Yield: 93%.

Embodiment 3

[0026] Dissolve compound VIII (1.97g) in ethanol (30ml), add Raney-Ni (0.6g) dissolved in ethanol, cool to 0℃ in an ice bath, add potassium borohydride (0.54g) in batches, and react at 0℃ for 28 After hours, the substrate disappeared, the solvent was removed by concentration under reduced pressure, and ethyl acetate (30ml) was added for extraction; the organic phase was washed with acid, alkali, saturated brine, and concentrated to obtain the final product. Yield: 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com