Hybrid fiber reinforced resin matrix sandwich structural absorbing material and its preparation method

A technology for strengthening resin-based and wave-absorbing materials, applied in synthetic resin layered products, chemical instruments and methods, layered products, etc., can solve the problems of difficult material preparation, difficult design, and difficulty in ensuring the stability of wave-absorbing performance. , to achieve the effect of good parameter latitude, excellent absorbing function and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

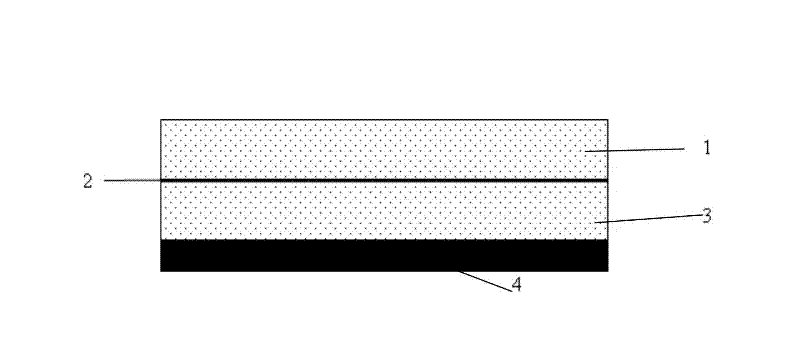

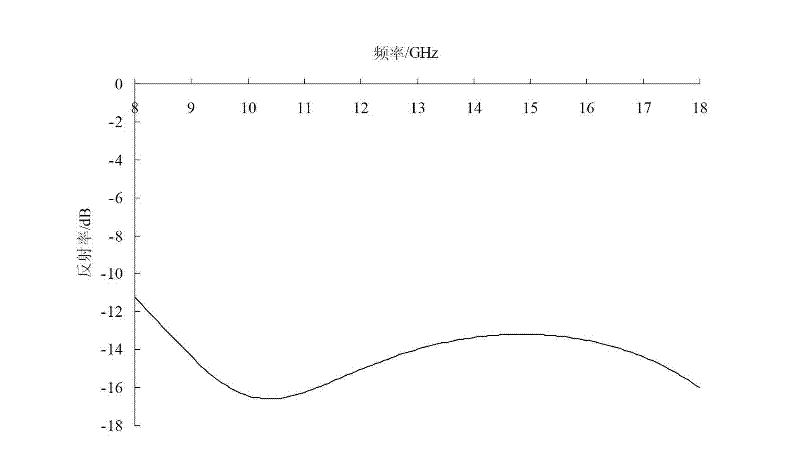

[0023] like figure 1 As shown in the figure, a hybrid fiber reinforced resin-based sandwich structure wave absorbing material of the present invention is a multifunctional multi-functional material comprising a first dielectric layer 1, an absorbing layer 2, a second dielectric layer 3 and a reflective layer 4 in sequence from outside to inside. A layer-by-layer structure, in which the first dielectric layer 1 and the second dielectric layer 3 are both composed of glass fiber reinforced resin matrix composite materials, TM glass fiber cloth acts as a reinforcing material, the total thickness of the first dielectric layer 1 is 2.3mm, and the second dielectric layer 1 is 2.3mm. The total thickness of the dielectric layer 3 is 2.4mm; the absorption layer 2 is composed of continuous silicon carbide fiber reinforced resin matrix composite material, and the continuous silicon carbide fiber acts as a reinforcing material, and its resistivity is 0.81Ω·cm, and the total thickness of the...

Embodiment 2

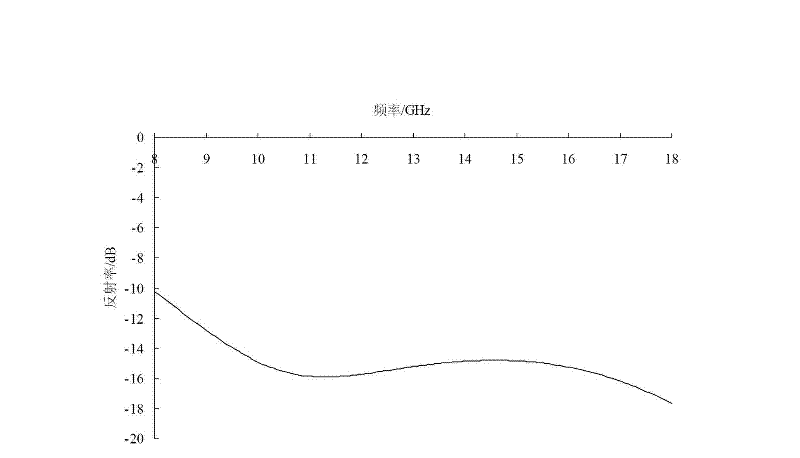

[0031] like figure 1 As shown, another hybrid fiber reinforced resin-based sandwich structure wave absorbing material of the present invention is a multi-layer structure comprising a first dielectric layer 1, an absorbing layer 2, a second dielectric layer 3 and a reflective layer 4 sequentially from outside to inside. Functional layer stacking structure, in which the first medium layer 1 and the second medium layer 3 are both composed of glass fiber reinforced resin matrix composite materials, E glass fiber cloth acts as a reinforcing material, the total thickness of the first medium layer 1 is 2.2mm, and the first medium layer 1 is 2.2mm thick. The total thickness of the second dielectric layer 3 is 2.3mm, the absorption layer 2 is composed of continuous silicon carbide fiber reinforced resin matrix composite material, the continuous silicon carbide fiber acts as a reinforcing material, and its resistivity is 0.92Ω·cm, and the total thickness of the absorption layer 2 is 0.36...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com