Method for preparing monodisperse silver core-nickel shell nanoparticles

A nanoparticle, monodisperse technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of non-catalytic application, uneven particle size distribution of products, failure to achieve monodispersity, etc. problem, to achieve the effect of wide application range, good monodispersity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

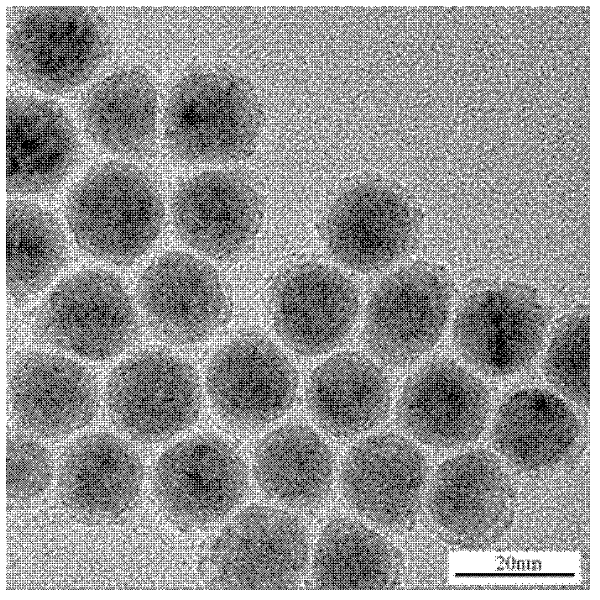

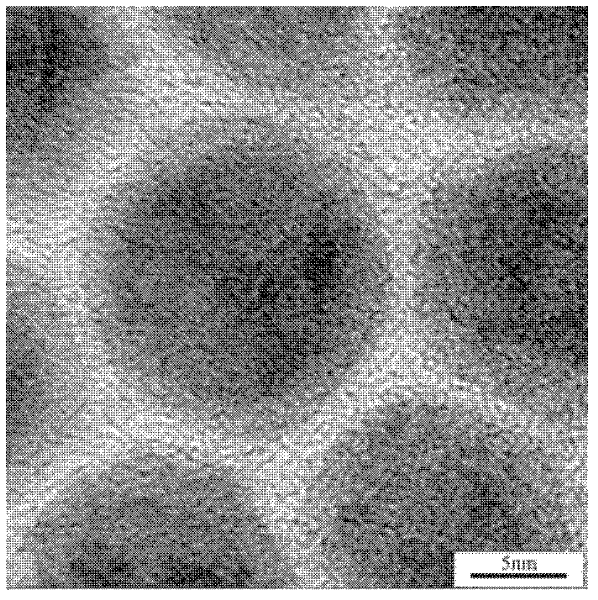

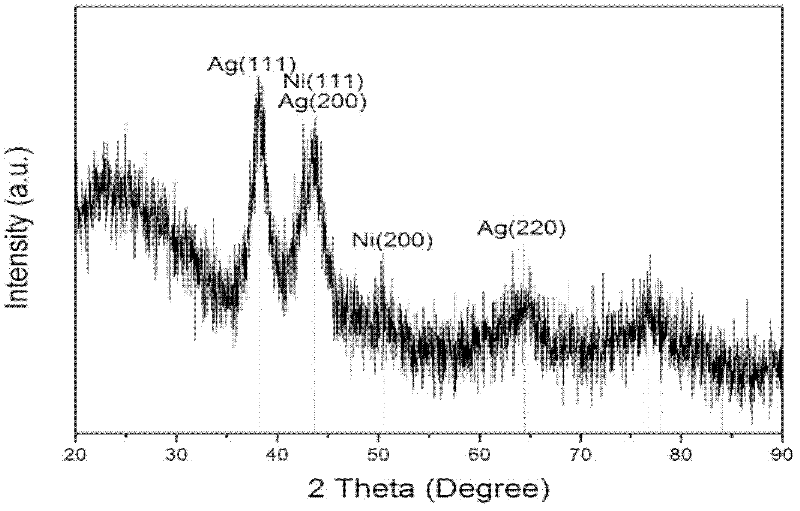

[0028] Add 0.4mmol nickel acetylacetonate, 0.1mmol silver nitrate, 0.6mmol triphenylphosphine and 6ml oleylamine into a three-neck flask, mix under the protection of argon, stir for 10min, then raise the temperature to 80°C, keep the temperature for 15min to fully mix the reactants Evenly, then slowly raise the temperature to 180°C, keep it warm for 40min, and then cool it naturally in the air to room temperature. Ethanol was added to precipitate the nanoparticles, and the reaction mother liquor was taken out by centrifugation, then washed three times with a mixed solution of acetone and n-hexane, and finally dried in vacuum to obtain a black powder. figure 1 It is a transmission electron microscope photo of the product, its appearance is spherical, the particle size distribution is narrow, and the particle diameter is about 15 nanometers; figure 2 It is a high-magnification transmission electron microscope photo of the product, and the core-shell structure can be clearly obs...

Embodiment 2

[0030]Add 0.4mmol nickel acetylacetonate, 0.1mmol silver nitrate, 0.3mmol triphenylphosphine and 6ml oleylamine into a three-necked flask, mix under the protection of argon, stir for 10min, then raise the temperature to 80°C, keep warm for 15min to fully mix the reactants Evenly, then slowly raise the temperature to 200°C, keep it warm for 60min, and then cool it naturally in the air to room temperature. Ethanol was added to precipitate the nanoparticles, and the reaction mother liquor was taken out by centrifugation, then washed three times with a mixed solution of acetone and n-hexane, and finally dried in vacuum to obtain a black powder. Figure 4 It is a transmission electron microscope photo of the product, its appearance is spherical, the particle size distribution is narrow, and the particle diameter is about 17 nanometers; Figure 5 It is a high-power transmission electron microscope photo of the product, and the core-shell structure can be clearly observed, and the th...

Embodiment 3

[0032] Add 0.4mmol nickel acetylacetonate, 0.1mmol silver nitrate, 0.1mmol triphenylphosphine and 6ml oleylamine into a three-neck flask, mix under the protection of argon, stir for 10min, then raise the temperature to 80°C, keep warm for 15min to fully mix the reactants Evenly, then slowly raise the temperature to 220°C, keep it warm for 60min, and then cool it naturally in the air to room temperature. Ethanol was added to precipitate the nanoparticles, and the reaction mother liquor was taken out by centrifugation, then washed three times with a mixed solution of acetone and n-hexane, and finally dried in vacuum to obtain a black powder. Image 6 It is a transmission electron microscope photo of the product, its appearance is spherical, the particle size distribution is narrow, and the particle diameter is about 19 nanometers; Figure 7 It is a high-power transmission electron microscope photo of the product, and the core-shell structure can be clearly observed, and the thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com