Flotation method for desulfurization and desilication of high-silicon bauxite

A bauxite and high-silicon technology, applied in flotation, solid separation, etc., can solve the problems of single bauxite flotation desulfurization or desiliconization, and achieve the effects of reverse flotation desiliconization and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

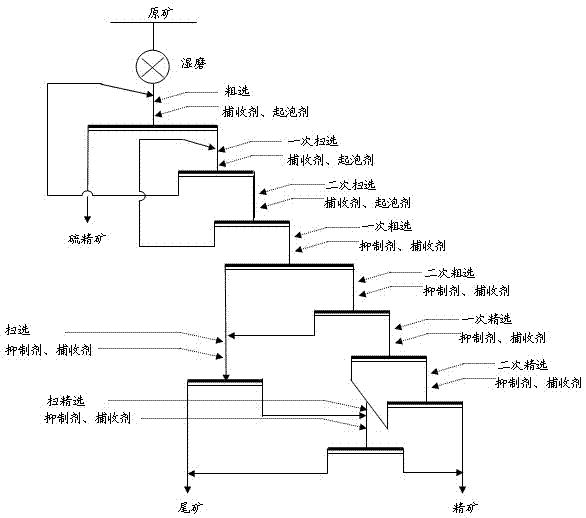

Image

Examples

Embodiment 1

[0017] (1) Wet-grind 1 ton of high-silicon bauxite until the ore with a grinding fineness of 74 μm accounts for 85%, adjust the mass concentration of the pulp to 38%, and enter normal temperature positive flotation desulfurization. The whole process adopts mass concentration 3% H 2 SO 4 The solution adjusts the pulp pH to 6.5: add 50g of butyl xanthate and isopentyl xanthate, add 60g of No. 2 oil for roughing operation, remove the flotation foam of roughing, add ethyl yellow to the remaining pulp of roughing Add 80g of medicine, add 20g of No. 2 oil to enter the first sweeping operation, and return the flotation foam of the first sweep to the roughing operation, add 100g of butyl xanthate and amyl xanthate, add 80g of pine oil and rough again 15g of butyl xanthate and 20g of No. 2 oil are added to the remaining pulp of the first sweep, and then the second sweep is carried out, and the flotation foam of the second sweep is returned to the first sweep to add Add 80g of ethyl x...

Embodiment 2

[0021] (1) Wet-grind 1 ton of high-silicon bauxite until the ore with a grinding fineness of 74 μm accounts for 95%, adjust the mass concentration of the pulp to 28%, and enter normal temperature positive flotation desulfurization. The whole process adopts mass concentration 2% H 2 SO 4The solution adjusts the pulp pH to 6.0: add 150g of amyl xanthate, 40g of No. 2 oil for roughing operation, remove the flotation foam of roughing, add 60g of isopentyl xanthate, add pine Oil 60g enters the first sweeping operation, and the flotation foam of the first sweeping returns to the roughing operation to add ethyl xanthate, butyl xanthate, pentyl xanthate and isopentyl xanthate 150g, add 2 40g of No. oil was roughed again, and 40g of amyl xanthate and isopentyl xanthate were added to the remaining pulp of the first sweep, and 10g of foaming agent was added, and then the second sweep was carried out. Select foam and return to the first sweeping operation, add 60g of butyl xanthate and ...

Embodiment 3

[0025] (1) Wet-grind 1 ton of high-silicon bauxite until the ore with a grinding fineness of 74 μm accounts for 90%, adjust the mass concentration of the pulp to 30%, and enter normal temperature positive flotation desulfurization. The whole process adopts mass concentration 4% H 2 SO 4 The solution adjusts the pulp pH to 6.5: Add 100g of butyl xanthate and 80g of No. 2 oil for roughing operation. After removing the flotation foam of roughing, add 40g of butyl xanthate and No. 40g of oil enters the first sweeping operation, and the flotation foam of the first sweeping is returned to the roughing operation, adding 50g of butyl xanthate, adding 60g of No. 2 oil for roughing again, and the remaining pulp of the first sweeping After adding 20g of butyl xanthate and 30g of No. 2 oil, enter the second scavenging operation, and the flotation foam of the second scavenging returns to the first scavenging operation, add 40g of butyl xanthate, and add No. 2 oil 40g is swept again, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com