Conical tri-rotor continuous mixing unit with rotors in linear arrangement

A conical three-rotor, in-line technology, used in mixers, mixers, dissolving and other directions with rotating stirring devices, can solve the problems of low efficiency and difficult to achieve the same mixing quality, and achieve higher output and higher mixing. The effect of refining and enhancing the effect of axial conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation plan

[0021] This implementation case is a two-stage conical three-rotor continuous mixing unit.

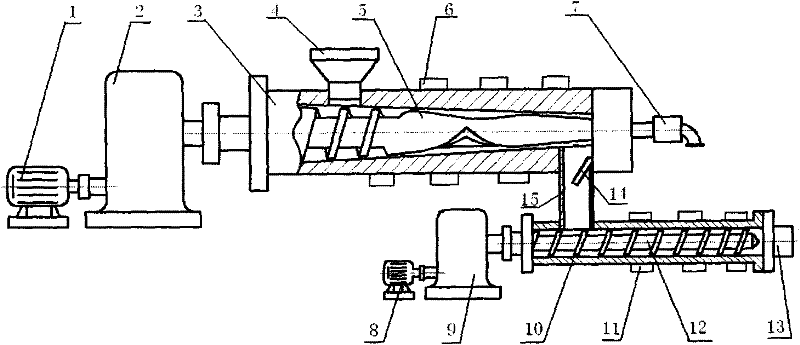

[0022] The conical three-rotor continuous mixing unit with conical rotors arranged in a straight line can be composed of a conical three-rotor continuous mixer connected with a screw extruder, see figure 1 . The mixing part mainly includes: motor 1, deceleration and distribution box 2, barrel 3, feeding device 4, heating device 5, conical rotor 6, and rotor cooling device 7. The screw extrusion part includes: a motor 8, a reduction box 9, a barrel 10, a heating device 11, a screw 12, and a nose die 13. The mixing part and the screw extruding part are connected by a cylinder 15, in which a discharge valve 14 with an adjustable opening is provided. Motor 1, deceleration and distribution box 2 form the transmission device of the equipment.

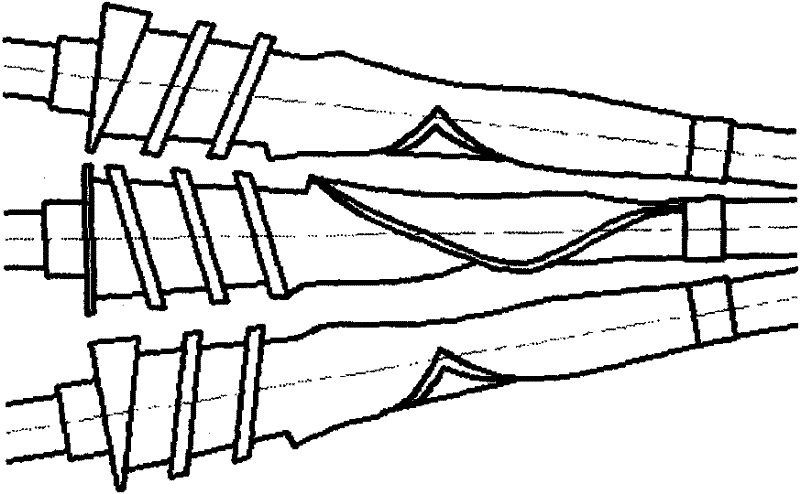

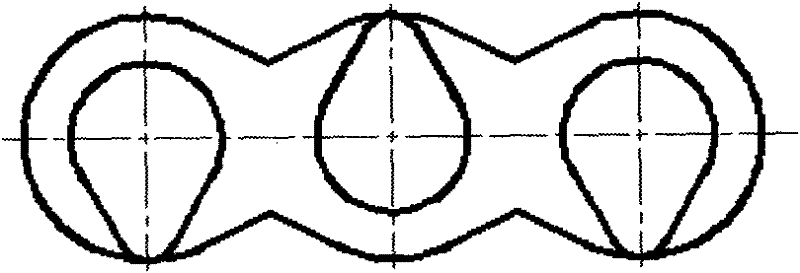

[0023] The mixing part uses three conical rotors, and when installed, their centerlines are located in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com