Pollution resistant membrane module and use method thereof

A membrane module, anti-pollution technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of increasing the concentration of dissolved organic matter in the supernatant, increasing the energy consumption of the flat membrane filtration system, and increasing the operating cost. and other problems, to achieve the effect of saving aeration energy consumption, slowing membrane pollution, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with the examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

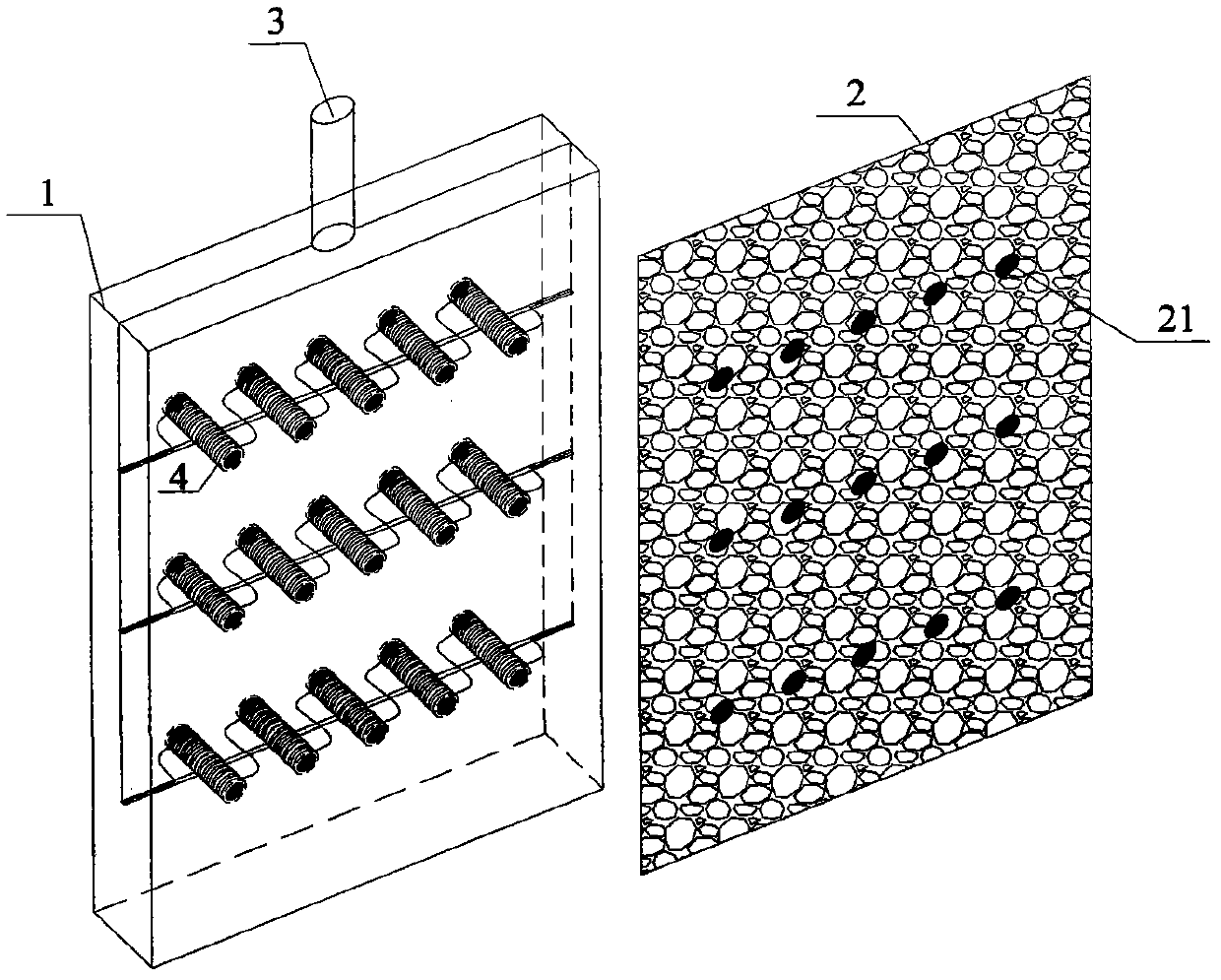

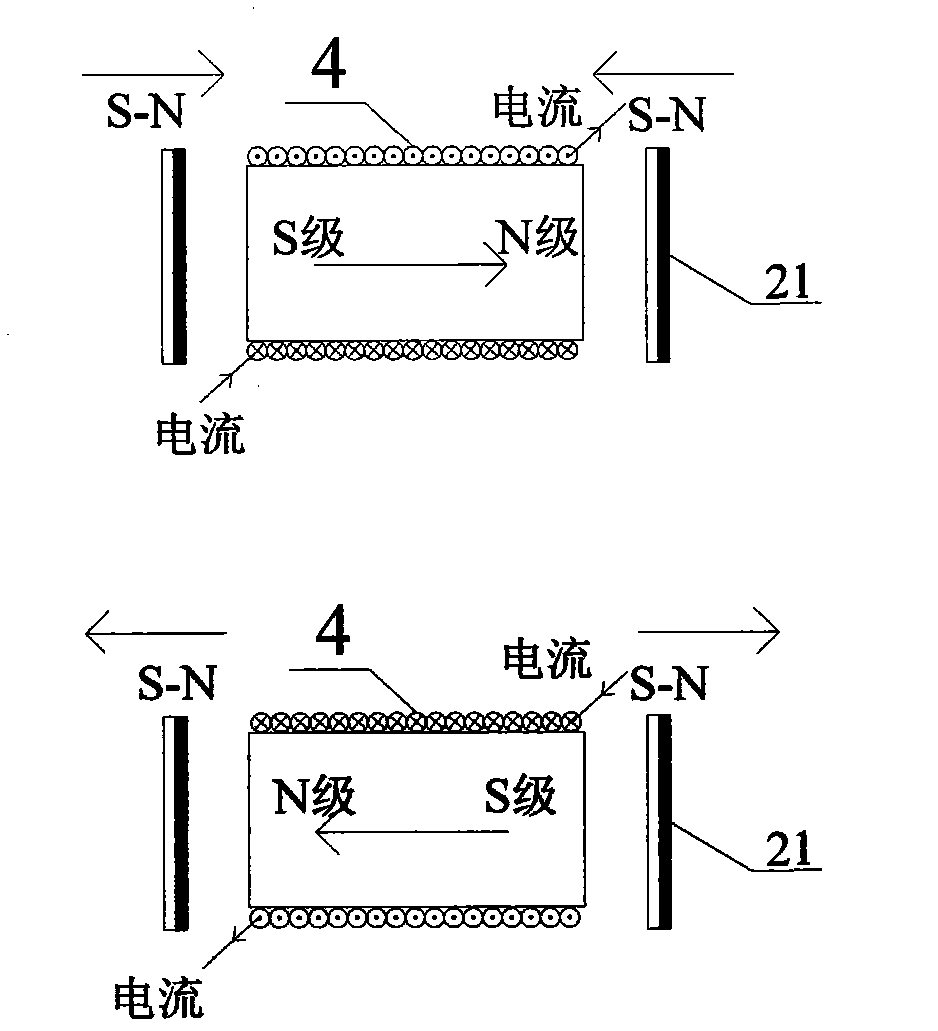

[0025] Please refer to figure 1 and figure 2 , figure 1 Schematic diagram of the structure of the anti-fouling membrane module provided for the specific embodiment of the present invention, figure 2 for figure 1 Side cutaway view of the anti-fouling membrane module shown. An anti-pollution membrane module provided by the present invention is a flat membrane module including a frame 1 and a filter membrane 2. The frame 1 can be made into a circle, a rectangle or a square, and the filter membrane 2 is two pieces, which are respectively covered on both sides of the frame 1. The frame 1 and the filter membrane 2 form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com