Curable resin composition and reflective sheet

A curable resin and composition technology, applied in the field of reflective sheets, can solve the problems of flexible substrates, etc., and achieve the effects of excellent adhesion, excellent resolution, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0108] In the curable resin composition of the present invention, a resin containing an ethylenically unsaturated group and a carboxyl group in one molecule, a bisacylphosphine oxide-based photopolymerization initiator, a monoacylphosphine oxide-based photopolymerization initiator, and A curable resin composition (hereinafter referred to as "composition 2") of titanium oxide, an organic solvent, a urethane acrylate, an epoxy compound, and an antioxidant is adjusted to a viscosity suitable for the coating method.

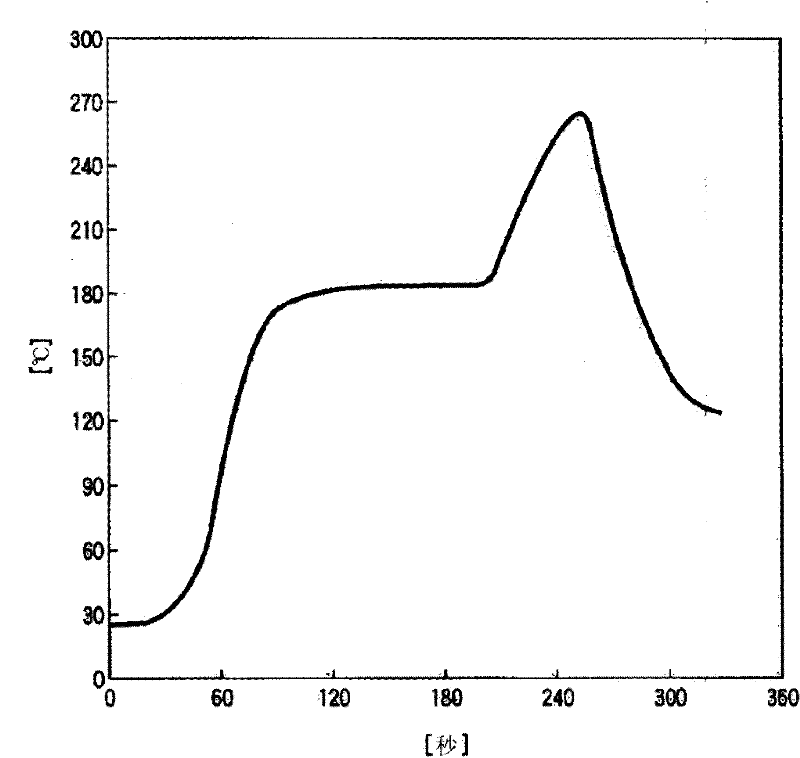

[0109] Next, the viscosity-adjusted composition 2 is coated on a flexible substrate by methods such as screen printing, curtain coating, spray coating, or roll coating. Then, the organic solvent contained in the composition 2 applied to the base material is volatilized and dried at a temperature of 70 to 90° C. to form a coating film (hereinafter referred to as “coating film 2 ”).

[0110] Then, the coating film 2 is selectively exposed to active energy rays through ...

Embodiment

[0115] The present invention will be specifically described below by showing examples and comparative examples, but the present invention is not limited to the following examples.

[0116] Synthesis of resin solution 1:

[0117]In a 2-liter detachable flask equipped with a stirrer, a thermometer, a reflux condenser, a dropping funnel, and a nitrogen inlet tube, 900 g of a solvent (diethylene glycol dimethyl ether), and 21.4 g of a polymerization initiator (tert-butyl 2-Ethylhexanoate peroxide, manufactured by NOF Corporation, brand name: Perbutyl O), was heated to 90°C. After heating, 309.9 g of methacrylic acid, 116.4 g of methyl methacrylate, and 109.8 g of lactone-modified 2-hydroxyethyl methacrylate (manufactured by DAICELCHEMICAL INDUSTRIES, LTD., trade name : PLACCEL FM1), and 21.4 g of a polymerization initiator (bis(4-tert-butylcyclohexyl)peroxydicarbonate, manufactured by NOF Corporation, brand name: PEROYL TCP). Further, by aging the mixture for 6 hours, a carboxyl...

Embodiment (1

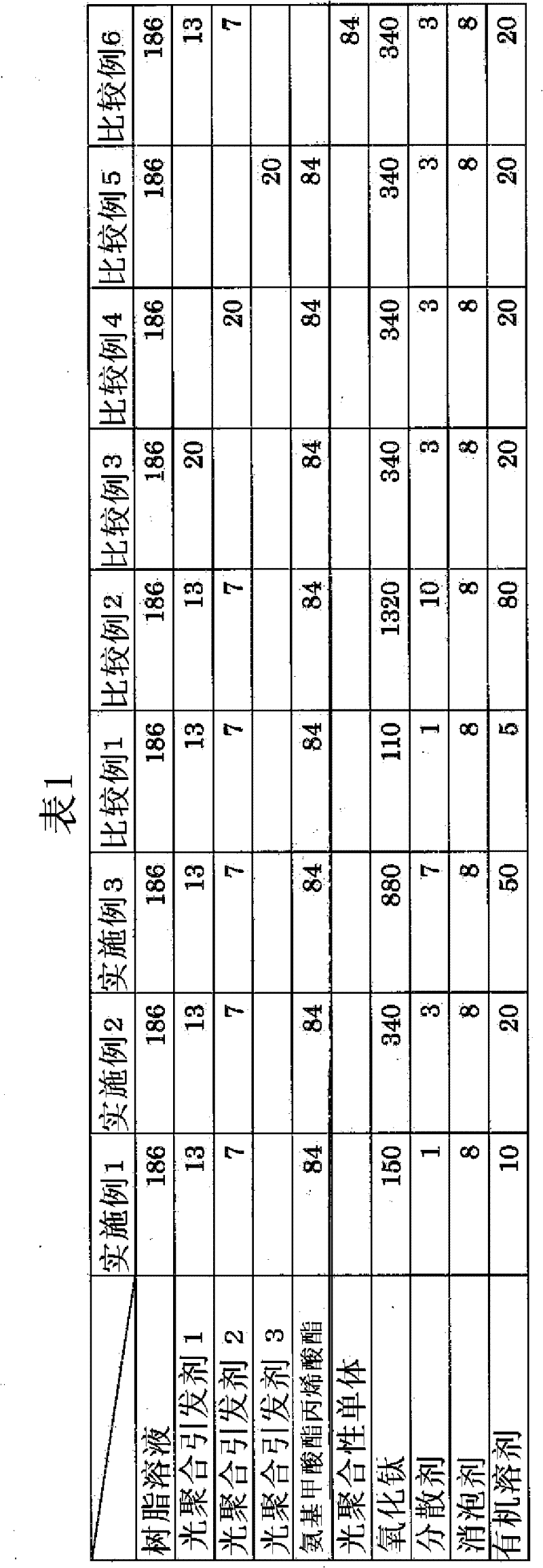

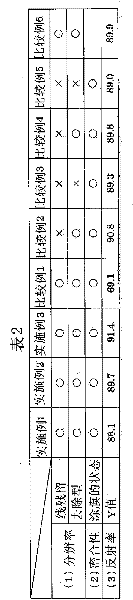

[0120] Preparation of each curable resin composition (Examples 1-3, Comparative Examples 1-6):

[0121] The mixture in which each component was blended as described in Table 1 was stirred, and further dispersed by a three-roll mill to prepare curable resin compositions (Examples 1-3, Comparative Examples 1-6). In addition, Comparative Example 1 shows a composition in which the compounding amount of titanium oxide is less than the specified compounding amount of the present invention, Comparative Example 2 shows a composition in which the compounding amount of titanium oxide is larger than the specified compounding amount in the present invention, and Comparative Example 3 shows a composition as a light A composition containing only BAPO as a polymerization initiator, Comparative Example 4 shows a composition containing only MAPO as a photopolymerization initiator, and Comparative Example 5 shows a composition containing a photopolymerization initiator other than BAPO and MAPO a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com