Method and device for preventing boiler waste heat recovery hot water from causing cavitation on boiler feed pump

A boiler feed water pump and hot water recovery technology, which is applied to supplementary feed water, preheating, pump components, etc., can solve the problems of increased production and installation costs, and achieve the effects of less installation cost, less reserve, and less surface heat dissipation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

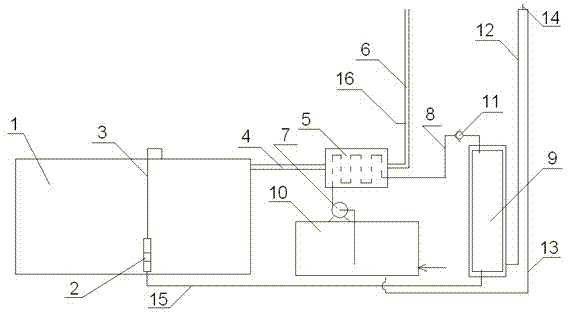

[0016] According to the above-mentioned method, the device for preventing boiler waste heat from recovering hot water from causing cavitation of the boiler feed pump is shown in the attached figure 2As shown, the boiler body 1 is included, the boiler body 1 is provided with a flue discharge pipe 4, and a heat exchanger 5 is installed in the flue discharge pipe section 4, the heat exchanger 5 is a water-cooled heat exchanger, and the heat exchanger 5 The water inlet of the water tank 10 communicates with the water supply tank 10, and the heat exchanger 5 replenishes water through the water supply tank 10; the water outlet of the heat exchanger 5 communicates with an external hot water tank 9 through a pipeline 8, and the heat exchanger is connected to the heat exchanger through a waste heat circulating water pump 7. The hot water in 5 is extracted and poured into the hot water tank 9, the bottom of the hot water tank 9 is provided with a hot water outlet, and the hot water outl...

Embodiment 2

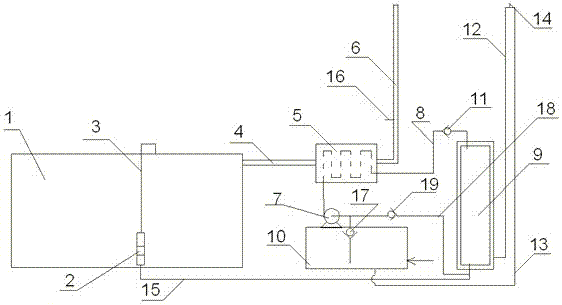

[0019] The basic structure of this embodiment is the same as that of Embodiment 1, but the layout of pipelines is slightly different. In this embodiment, a circulation branch pipe 18 is connected to the water supply line 15 connecting the hot water tank to the boiler feed water pump. The water supply inlet pipelines are connected, and at the same time, the suction pipe section of the water supply inlet pipeline of the waste heat circulating water pump 7 is provided with an electronically controlled one-way valve 17, and the electronically controlled one-way valve 17 is closed when the water in the hot water tank 9 is sufficient. A one-way circulation loop is formed between the heat exchanger 5, the waste heat circulating water pump 7 and the hot water tank 9, so that the water temperature of the hot water tank can be further increased; at the same time, in order to prevent water from directly flowing into the boiler feed water pump 2 from the circulation branch pipe 18, in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com