Bituminous mixture modifier as well as preparation method and application thereof

A technology of asphalt mixture and modifier, which is applied in the field of asphalt mixture modifier and its preparation, and can solve the problems of not finding asphalt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

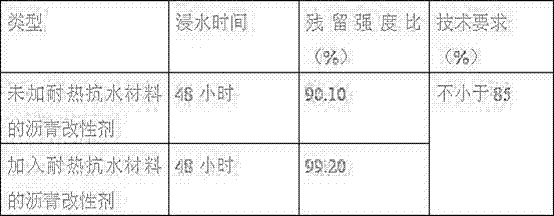

Image

Examples

Embodiment 1

[0025] Add 67% polyethylene to 5% natural asphalt, and mix evenly in a high-speed mixer, then add 20% petroleum resin and 7% glass hollow microspheres, and continue to mix evenly; put the evenly mixed material into the twin-screw The extruder is heated to 150-170 degrees to form a molten mixture and then extruded; in the water cooling process, it is kept at 130-150 degrees to pelletize to obtain the finished product.

Embodiment 2

[0027] Add 37% polyethylene and 36% polypropylene to 9% petroleum asphalt, and mix evenly in a high-speed mixer, then add 15% petroleum resin and 3% organic water-resistant materials, and continue to mix evenly; mix evenly The final material is put into a twin-screw extruder, heated to 150-170 degrees to form a molten mixture and then extruded; during the water cooling process, it is pelletized in an environment of 130-150 degrees to obtain a finished product. The organic water-resistant material is an organic double-layer thermoplastic structure microsphere; it is a double-layer structure composed of an airbag structure and an outer copolymer shell, and the copolymer is vinylidene chloride and acrylonitrile or the two. A kind of polymer, the airbag structure is isobutane or isopentane. The expanded diameter of the bilayer thermoplastic structure is typically 10-200 μm; for unexpanded microspheres, the diameter before expansion is typically 20-60 μm.

Embodiment 3

[0029] Add 59% polypropylene to 5% petroleum asphalt, and mix evenly in a high-speed mixer, then add 24% petroleum resin and 12% glass hollow microspheres, and continue to mix evenly; put the evenly mixed material into the twin-screw The extruder is heated to 150-170 degrees to form a molten mixture and then extruded; in the water cooling process, it is kept at 130-150 degrees to pelletize to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com