Method for manufacturing lithium ion battery and rolled core thereof and lithium ion battery

A lithium ion battery and a manufacturing method technology, applied in the field of lithium ion batteries, can solve the problems of increasing the hidden danger of battery safety, large friction coefficient of aluminum foil, increasing the difficulty of entering the shell, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

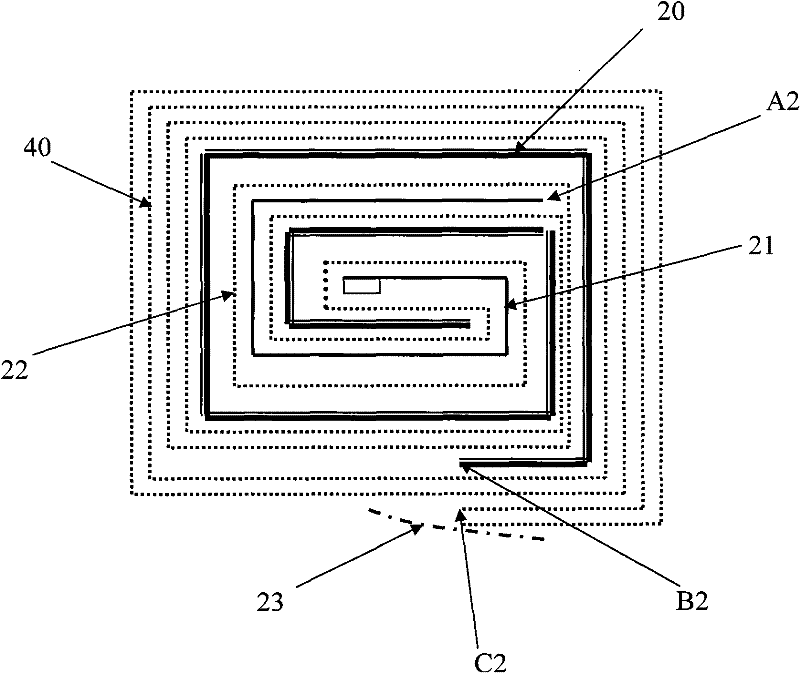

[0021] see figure 2 , this embodiment relates to a manufacturing method of a lithium-ion battery. After the separator 22 isolating the positive electrode sheet 20 and the negative electrode sheet 21 is wrapped around the ends A2 and B2 of the negative electrode sheet and the positive electrode sheet, it continues to extend, and winds a coil around the core. circle or more than one circle to form a diaphragm protection layer 40 on the outermost layer of the winding core. The friction coefficient of the diaphragm protection layer 40 is small, which is beneficial to the installation of the winding core into the shell. The potential safety hazards brought about by the use of lithium-ion batteries.

[0022] This embodiment also relates to a lithium-ion battery, including a battery case, a winding core accommodated in the battery case, and an electrolyte injected into the battery case. figure 2 Shown is a cross-sectional view of core winding in this embodiment. Among them, 20 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com