Medium-temperature sintered magnesium titanate-based microwave dielectric ceramics with high quality factor

A technology of microwave dielectric ceramics and high quality factor, which is applied in the field of magnesium titanate-based microwave dielectric ceramics, can solve the problems that the dispersion of ceramic powder has not been widely studied, and achieve time and energy cost saving, wide application, and production process The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

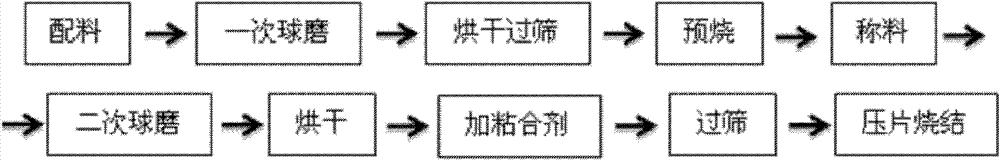

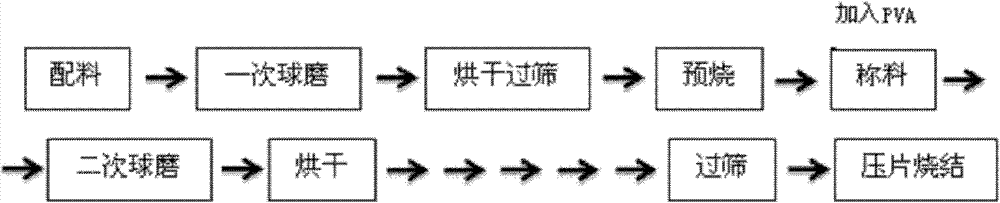

Method used

Image

Examples

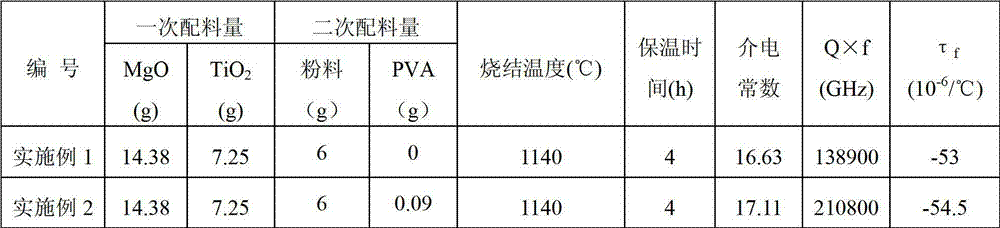

Embodiment 1

[0023] According to microwave dielectric ceramic composition MgTiO 3 , Weigh TiO 2 14.38g, 7.25g of MgO, the mixed powder is put into a nylon tank, 150ml of deionized water and 150g of zirconium balls are added, and then ball milled on a planetary ball mill for 12 hours at a speed of 1000 rpm. After discharging, it is placed in a drying box for drying at 120°C and passed through a 40-mesh sieve, and the powder is calcined at 900°C for 2 hours. Weigh 6g of powder and place it in a nylon tank, then add 150ml of deionized water and 150g of zirconium balls, and then ball mill on a planetary ball mill for 12 hours at a speed of 1000 rpm. After the material is discharged, it is placed in a drying box for drying at 120°C, paraffin is added for granulation, and sieved to 80 meshes, and then pressed into a green compact with a diameter of 10 mm and a height of 5 mm with a powder tablet machine at a pressure of 4 MPa. The green body was sintered at 1140°C for 4 hours to obtain microwave ...

Embodiment 2

[0025] According to microwave dielectric ceramic composition MgTiO 3 , Weigh TiO 2 14.38g, MgO7.25g ingredients, mixed powder into nylon

[0026] After adding 150ml of deionized water and 150g of zirconium balls to the tank, ball mill on a planetary ball mill for 12 hours at a speed of 1000 rpm. After discharging, it is placed in a drying box for drying at 120°C and passed through a 40-mesh sieve, and the powder is calcined at 900°C for 2 hours. Weigh 6g of powder and place it in a nylon tank, add 0.09g of PVA (model 1788) powder, then add 150ml of deionized water and 150g of zirconium balls, then ball mill on a planetary ball mill for 12 hours at a speed of 1000 revolutions / Minute. After the material is discharged, it is placed in a drying box for drying at 120°C, and after sieving 80 meshes, it is then pressed into a green body with a diameter of 10mm and a height of 5mm with a powder tablet press at a pressure of 4MPa. The green body was sintered at 1140°C for 4 hours to ob...

Embodiment 3

[0028] According to microwave dielectric ceramic composition MgTiO 3 , Weigh TiO 2 7.99g, MgO4.03g ingredients, the mixed powder is put into a nylon tank, 150ml deionized water and 150g zirconium balls are added, and then ball milled on a planetary ball mill for 12 hours at a speed of 1000 rpm. After discharging, it is placed in a drying box for drying at 120°C and passed through a 40-mesh sieve, and the powder is calcined at 900°C for 2 hours. Weigh 6g of powder and place it in a nylon tank, add 0.09g of PVA (model 1788) powder, then add 150ml of deionized water and 150g of zirconium balls, then ball mill on a planetary ball mill for 12 hours at a speed of 1000 revolutions / Minute. After the material is discharged, it is placed in a drying box for drying at 120°C, and after sieving 80 meshes, it is then pressed into a green body with a diameter of 10mm and a height of 5mm with a powder tablet press at a pressure of 4MPa. The green body was sintered at 1140°C for 4 hours to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| dielectric properties | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com