Pumice straw lightweight aggregate concrete and preparation method thereof

A lightweight aggregate concrete and straw technology, which is applied in ceramic products, other household utensils, sustainable waste treatment, etc., can solve the problems of poor workability between light raw materials and concrete, high density of lightweight aggregate concrete, and poor thermal insulation effect Good and other problems, to achieve the effect of light weight, reduced cement consumption, good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

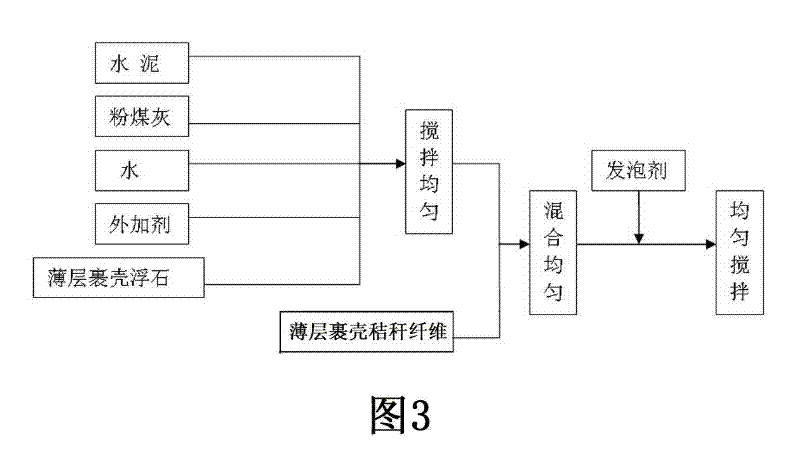

Embodiment 1

[0040] Embodiment 1, this kind of pumice straw light aggregate concrete, its raw material ratio by weight is as follows:

[0041] 1 part of cement;

[0042] 0.43 parts of fly ash;

[0043] 2.3 parts of pumice sand;

[0044] Corn straw fiber 0.04 part;

[0045] Admixture 0.015 parts;

[0046] Foaming agent 0.006 part;

[0047] 0.53 parts of water.

Embodiment 2

[0048] Embodiment two, this kind of pumice straw light aggregate concrete, its raw material proportioning by weight is as follows:

[0049] 1 part of cement;

[0050] 0.42 parts of fly ash;

[0051] 2.55 parts of pumice sand;

[0052] Corn straw fiber 0.05 parts;

[0053] Admixture 0.012 parts;

[0054] Foaming agent 0.007 part;

[0055] 0.55 parts of water.

Embodiment 3

[0056] Embodiment three, this kind of pumice straw light aggregate concrete, its raw material proportioning by weight is as follows:

[0057] 1 part of cement;

[0058] 0.50 parts of fly ash;

[0059] 2.05 parts of pumice sand;

[0060] Corn straw fiber 0.05 parts;

[0061] Admixture 0.010 parts;

[0062] Foaming agent 0.005 part;

[0063] 0.55 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com