Sewage pretreatment tank

A technology for sewage pretreatment and tank body, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Unable to realize the integrated process of the pretreatment stage and other problems, to achieve the effect of shortening the sewage pretreatment process, saving time, and saving land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

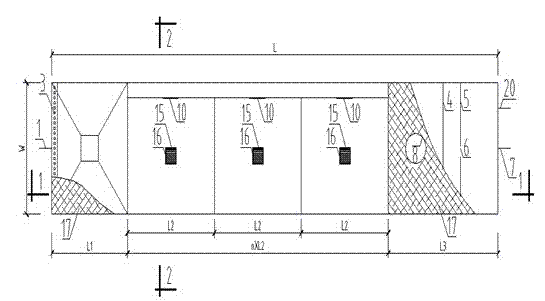

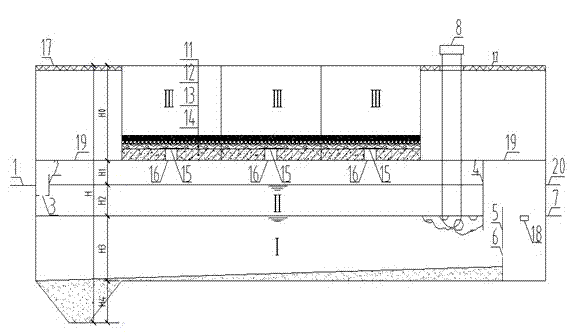

[0035] A sewage pretreatment tank provided by the present invention includes a mud collecting device located at the lower part of the tank body, the mud collecting device is connected with a mobile mud discharge device, and here, the mud collecting device is a sludge bucket; The upper part of the mud hopper is connected with a sedimentation oil separation area I, and the two lateral ends of the sedimentation oil separation area I are provided with a raw water inlet device 1 and a water outlet opposite to the raw water inlet device 1. Here, the raw water The water inlet device 1 includes a raw water inlet pipe 1 protruding from the outside of the tank body to the sedimentation oil separation zone I, the raw water inlet pipe 1 communicates with the water inlet tank 2, and an inlet is arranged on the bottom plate of the water inlet tank 2. Water hole 3 (see figure 1 and figure 2 ); the water outlet end is provided with a water outlet device, and here, the water outlet device in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com