A kind of reduction reaction system and method of laterite nickel ore water-containing pellets

A technology of laterite nickel ore and water-containing pellets, which is applied in the field of chemical metallurgy, can solve problems such as weak power infrastructure, influence on normal production, and low equipment operation rate, reduce production costs and equipment investment, shorten pretreatment processes, and solve The effect that the burner is easy to clog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

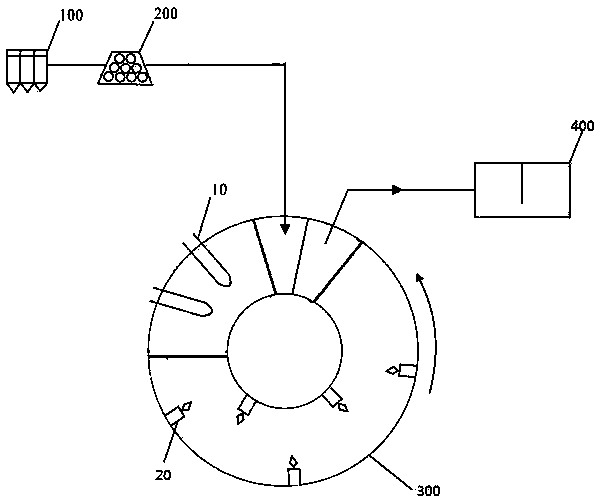

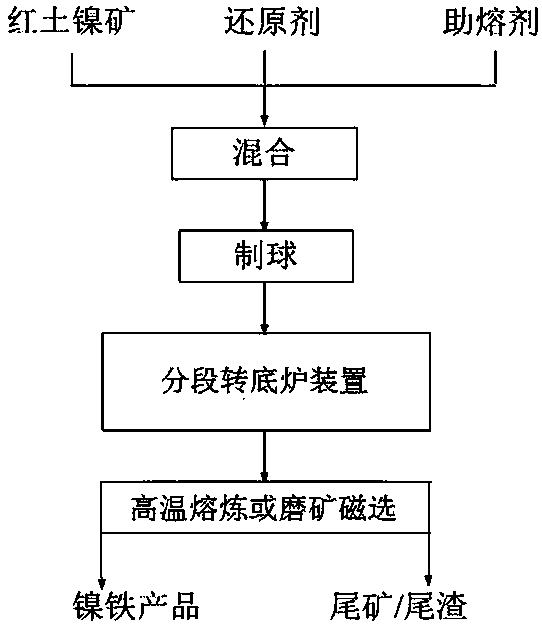

Embodiment 1

[0051] Choose laterite nickel ore with TFe21.8% and Ni 1.58% as raw material, first crush the laterite nickel ore to less than 3mm, and mix according to the ratio of reducing agent addition to 1.0 times of the theoretical addition amount without adding flux- Pressed balls, the moisture content of the pressed water-containing pellets is 14%, and the pressed water-containing pellets are directly distributed into the sectional rotary hearth furnace device for drying and reduction treatment. The drying area of the sectional rotary hearth furnace device is heated by a drying tube and dried The heat source of the tube comes from the natural gas supply device, and the reduction zone is heated by a regenerative burner; the included angle of the circle in the drying zone is 30°, and the angle between the circles in the reduction zone is 270°; the minimum temperature in the drying zone is 900°C, the reduction The highest temperature in the zone is 1350°C; the segmented rotary hearth fu...

Embodiment 2

[0053]Select laterite nickel ore with TFe17.1% and Ni 1.80% as raw material, first crush the laterite nickel ore to less than 1mm, add 1.5 times the theoretical amount of reducing agent, and add limestone to the weight of the laterite nickel ore 10% for mixing and pelletizing, the moisture content of the water-containing pellets is 18%, and the pressed water-containing pellets are directly distributed into the sectional rotary hearth furnace device for drying-reduction treatment, and the drying area of the sectional rotary hearth furnace device is heated by a drying tube , the heating method of the drying tube is electric heating, and the reduction area is heated by a burner; the included angle of the ring in the drying area is 90°, and the included angle of the ring in the reduction area is 210°; the minimum temperature in the drying area is 700°C, and the reduction The maximum temperature in the zone is 1300°C; the sectional rotary hearth furnace device rotates for 60 minut...

Embodiment 3

[0055] Select laterite nickel ore with TFe41.0% and Ni 1.30% as raw material, first crush the laterite nickel ore to less than 2mm, add reducing agent to 0.8 times the theoretical addition amount, and add quicklime to the weight of the laterite nickel ore 5% for mixing-pelleting, the moisture content of the water-containing pellets is 19%, and the pressed water-containing pellets are directly distributed into the sectional rotary hearth furnace device for drying-reduction treatment, and the drying area of the sectional rotary hearth furnace device is used for drying. Heating, the heat source of the drying tube comes from a gas generator, and the reduction zone is heated by a burner; the included angle of the ring in the drying zone is 140°, and the included angle of the ring in the reduction zone is 160°; the minimum temperature in the drying zone is 900°C, and the reduction The highest temperature in the zone is 1250°C; the segmented rotary hearth furnace rotates for 90 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com