Waste gas recycling buffer system of vulcanizing tank

A waste gas recovery and buffer system technology, applied in chemical instruments and methods, separation of dispersed particles, use of liquid separation agents, etc., can solve problems such as accidents, small amounts of solids, and blocked pipelines, and achieve reasonable design, simple structure, Solve the effect of easy clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

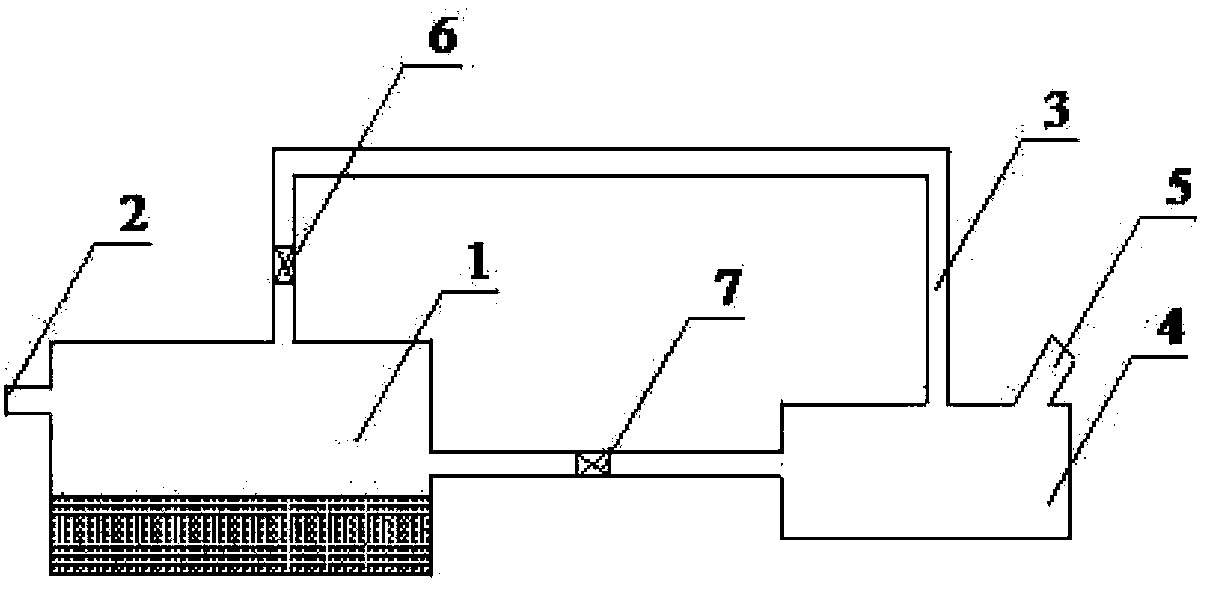

[0012] A vulcanization tank waste gas recovery buffer system of the present invention comprises a waste gas recovery tank 1, the waste gas recovery tank 1 is provided with an inlet pipe 2 and an air outlet pipe 3, and there is a certain amount of absorption liquid in the waste gas recovery tank 1, and the waste gas recovery tank 1 passes through the pipe Road links to each other with glove box 4, and buffer pipe 5 communicates with the outside world on the glove box 4, and air outlet pipe 3 communicates with glove box 4.

[0013] An exhaust valve 6 is provided between the outlet pipe 3 and the exhaust gas recovery tank 1 , and a safety overflow valve 7 is provided between the glove box 4 and the exhaust gas recovery tank 1 .

[0014] The exhaust gas recovery process mainly absorbs and treats the exhaust gas through the absorption liquid in the exhaust gas recovery tank 1. According to common sense, the absorption liquid in the exhaust gas recovery tank 1 also needs to be update...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com