Internal tooth type high shear colloid mill

A colloid mill, high shear technology, used in cocoa, grain processing, food science, etc. to increase fluidity and save heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

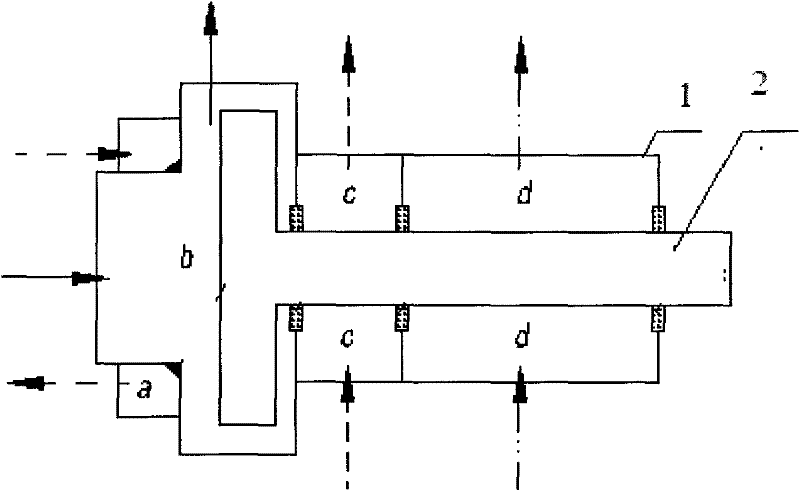

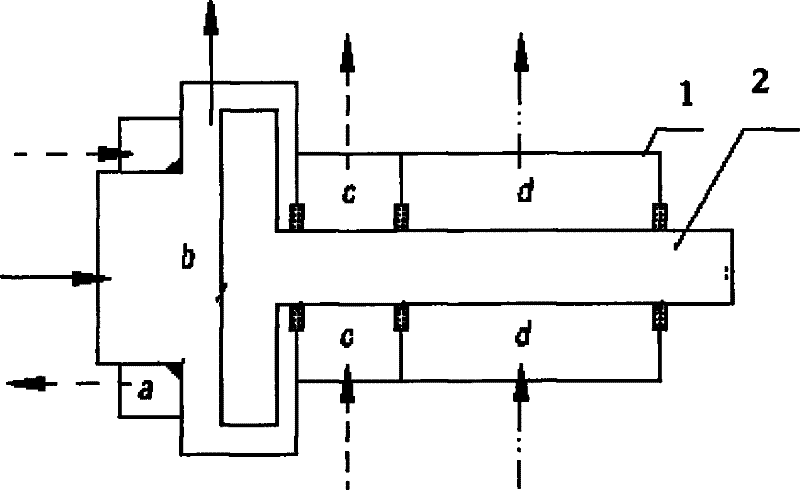

[0007] A high-shear colloid mill, which includes a colloid mill housing 1 and a rotor 2, the rotor 2 is connected to the colloid mill housing 1, and the colloid mill housing 1 is provided with a heat-conducting oil chamber a, an asphalt medium chamber b, Water medium cavity c and lubricating medium cavity d. The four cavities are mutually independent in the colloid mill housing 1 and are mutually sealed.

[0008] The asphalt enters the colloid mill asphalt medium cavity b from the suction port of the shell 1, and the medium is ground in the colloid mill asphalt medium cavity b hundreds of thousands of times under the high-speed rotation of the rotor 2. In the process from the suction port to the outlet, the grinding area of each stage is constantly changing due to the radial depth, so that the direction and instantaneous speed of the medium are constantly changing. When being sheared by the cutter teeth, the intense friction, extrusion and kneading between the molecules make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com