Electrolytic extraction and detection method of nonmetallic inclusion in steel by utilizing organic solution

A technology of non-metallic inclusions and organic solutions, which is applied in the field of metal electrochemistry, can solve the problems of inaccurate chemical composition, easy destruction of inclusions, long electrolysis time, etc., and achieve convenient and effective preparation, short test cycle and improved efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

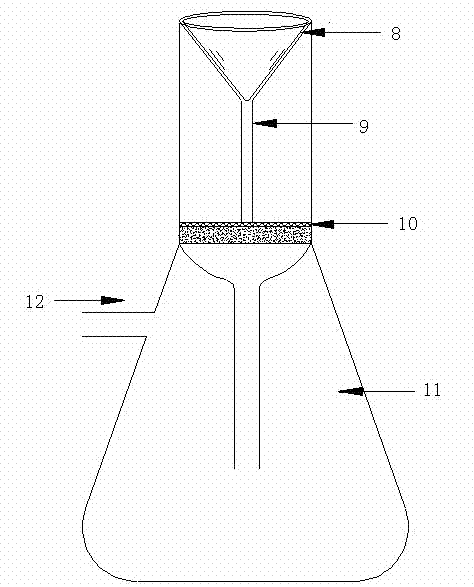

[0033] First prepare the electrolyte, the formula of the electrolyte is as follows: (wt%) tetramethylammonium chloride 1%, acetylacetone 23%, analytically pure methanol as the balance. figure 1 It is a schematic diagram of the electrolytic extraction of inclusions in steel used in the present invention. The electrolytic surface of the steel sample containing oxide inclusions is immersed in the electrolyte, and a salt tank is arranged next to the electrolytic tank, and saturated Potassium chloride solution, a salt bridge is set up between the salt tank and the electrolytic tank, and a calomel electrode is inserted in the salt tank, the calomel electrode is connected to a DC regulated power supply, and the steel sample is connected to the positive pole of a DC regulated power supply as an anode. The platinum wire is used as the electrolysis cathode, and the inert gas argon is passed through, the flow rate is controlled at 0.2 liters / min, the control voltage is 4V, the temperature...

Embodiment 2

[0036] The electrolyte solution used in this embodiment is exactly the same as that of the above-mentioned embodiment 1.

[0037] figure 1 It is a schematic diagram of the electrolytic extraction of inclusions in steel used in the present invention, the electrolytic surface of the steel sample containing calcium silicate inclusions is immersed in the electrolyte, and a salt tank is arranged next to the electrolytic tank, and the salt tank is placed Saturated potassium chloride solution, set up a salt bridge between the salt tank and the electrolytic tank, insert a calomel electrode in the salt tank, connect the calomel electrode to a DC regulated power supply, and connect the steel sample to the positive pole of the DC regulated power supply as an anode , the platinum wire is used as the cathode, and the inert gas argon is passed through, the flow rate is controlled at 0.3 liters / min, the control voltage is 3.5V, the temperature of the electrolyte is 0~15°C; the cathode DC cur...

Embodiment 3

[0039] The electrolyte solution used in this embodiment is exactly the same as that of the above-mentioned embodiment 1. Immerse the electrolytic surface of the steel sample containing calcium aluminosilicate inclusions in the electrolyte, and arrange a salt tank next to the electrolytic tank, and place a saturated potassium chloride solution in the salt tank, and set up between the salt tank and the electrolytic tank The calomel electrode is inserted into the salt tank, and the calomel electrode is connected to a DC regulated power supply. The steel sample is connected to the positive pole of the DC regulated power supply as the anode, and the platinum wire is used as the cathode. The flow control is 0.3 liters / min, the control voltage is 4V, the temperature of the electrolyte is 0~15℃; the cathode DC current density is 0.022~0.042A / cm 2 , The electrolysis time is 5 hours, and the amount of electrolyte is 0.7915 grams.

[0040] Then pour the above electrolytic solution into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com