High-flame-retardance wood fireproof door and making method thereof

A fire door, high flame retardant technology, applied in the field of fire doors, can solve the problems of high smoke and toxic gas emission, low flame retardant performance, secondary pollution, etc. flammability and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

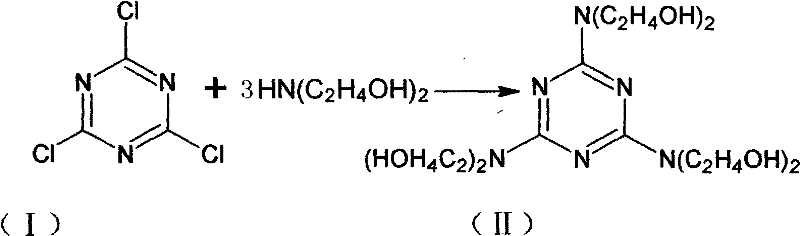

[0015] a. In a reaction kettle, ethanol is used as a solvent, and cyanuric chloride (I) and bishydroxyethylamine are reacted at 60° C. to 90° C. for 5 to 7 hours under the action of alkali catalyst sodium carbonate to generate compound three (N, N -dihydroxyethylamino)-s-triazine;

[0016] b. Heat the compound tris(N,N-dihydroxyethylamino)-s-triazine and one or more of them containing phosphorus pentoxide, pyrophosphoric acid or polyphosphoric acid at a temperature of 80°C to 110°C React for 4-6 hours to generate tris(N,N-dihydroxyethylamino)-s-triazine phosphate flame retardant compound;

[0017] C. Add the synthesized s-triazine phosphate flame retardant compound into the mixing tank to dilute and stir for 30 minutes with 2 times pure water, then put it into a microwave heating vacuum softening wood tank, and place the wooden fire doors made in a microwave heating Vacuum softening wood tank sealed vacuum pressure, microwave heating to 80 ~ 90 ℃, heat preservation impregnati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com