Simulative calculation method for engine lubrication system

A lubrication system and simulation calculation technology, applied in the field of simulation calculation of the lubrication system, can solve the problems of waste of manpower and material resources, inability to effectively control the performance of the lubrication system, and inability to control the performance of the lubrication system, and achieve the effect of optimal design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment of various embodiments of the present invention.

[0028] In this embodiment, a computer numerical simulation is performed on a certain gasoline engine lubrication system. Through this analysis, the purpose of this analysis is to find out the cause of the low oil pressure based on the detailed pressure and flow distribution results; to compare and analyze the results of nozzle diameters and cylinder head orifice diameters of different timing chains, and then to compare nozzles and throttles. Reasonable recommendations are given for orifice diameter.

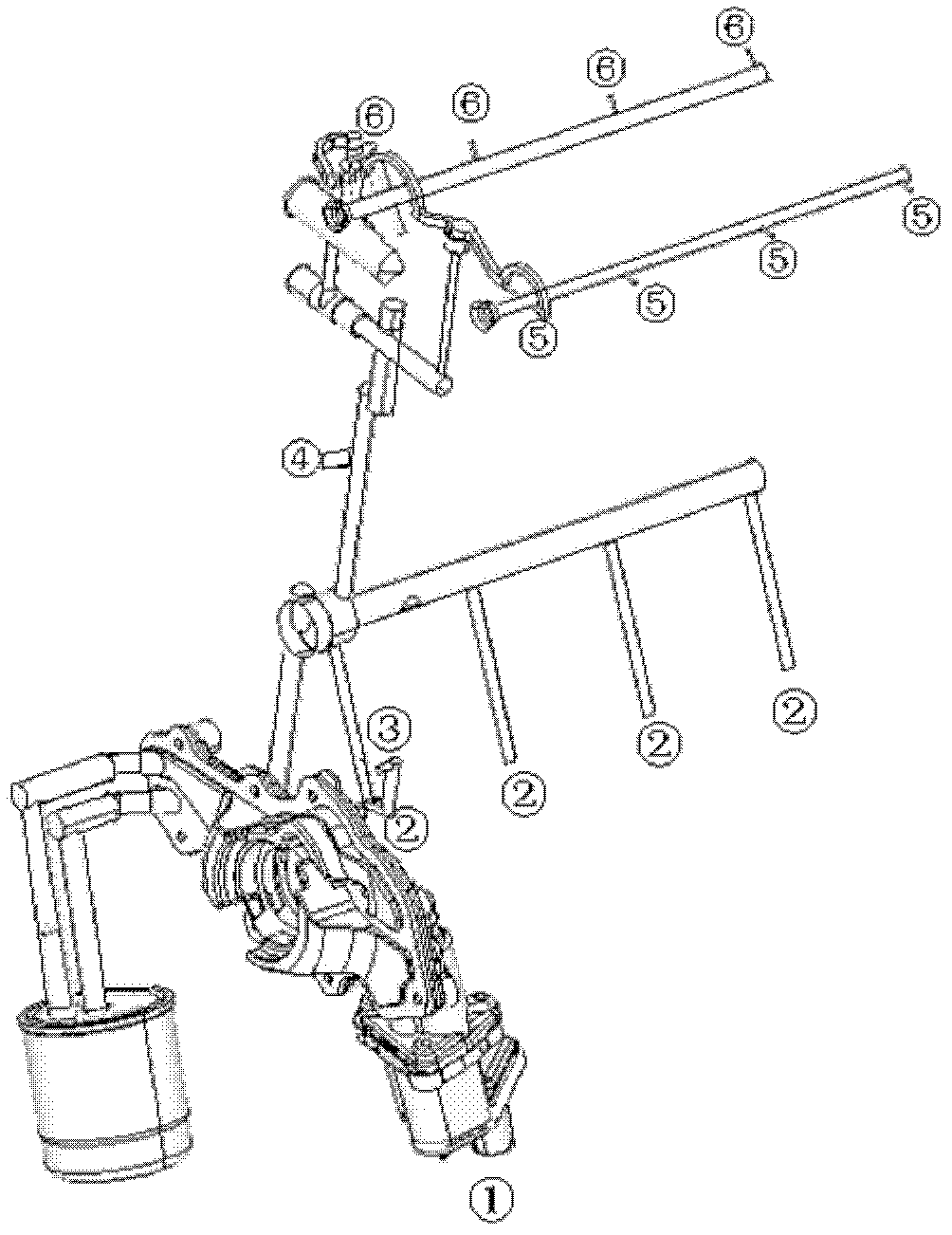

[0029] figure 1 Flow chart for simulation calculation of engine lubrication system. First according to figure 2 The lubrication system model in, collect relevant data, including oil pump characteristic curve; oil pipe length and diameter; main bearing, connecting rod bearing clearance, size, etc. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com