Preparation method of self-assembly vanadium oxide film

A vanadium oxide film and self-assembly technology, which is applied in the field of self-assembly preparation of vanadium dioxide film, can solve the problems of complicated process, not easy to buy, toxicity of vanadium powder, etc., and achieve simplified process flow and redox reaction speed Effect of reduction, low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

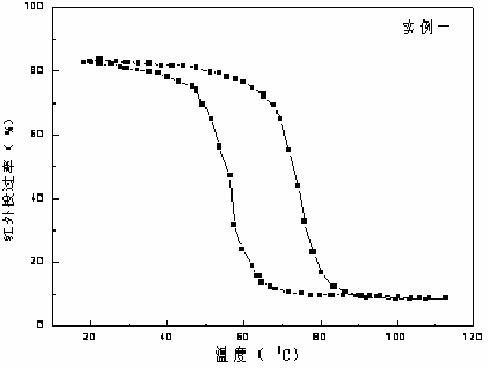

Embodiment 1

[0022] A method for preparing a self-assembled vanadium oxide film, comprising the following steps.

[0023] (1) Clean the substrate ultrasonically with acetone solution first, then ultrasonically clean it with deionized water, and finally clean it ultrasonically with absolute ethanol and dry it; (2) Put the dried substrate in step (1) Put it into the octadecyltrichlorosilane-toluene solution with a concentration of 1%, let it stand for 30 minutes, take it out, and then irradiate it with ultraviolet light for 10 minutes; (3), put V 2 o 5 and ascorbic acid dissolved in water, V 2 o 5 The mass ratio to ascorbic acid is 1:2, add dilute HCl to adjust the pH to 5, heat to 30°C and stir for 30 minutes to dissolve into a transparent and clear blue solution A; 2 o 5 Mass of 1% cerium acetate and mass of V 2 o 5 Dissolve 1% ammonium paratungstate in water, add dilute HCl to adjust the pH to 5 to form solution B; mix solution A and solution B, add polyethylene glycol with a concen...

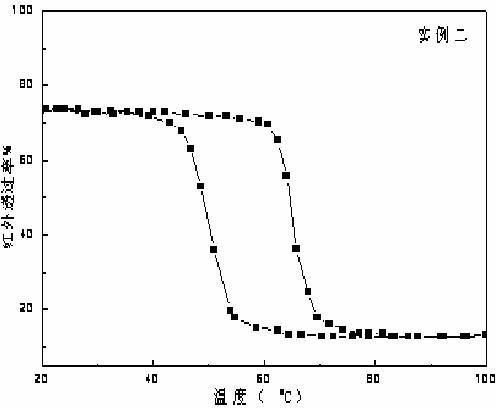

example 2

[0025] A method for preparing a self-assembled vanadium oxide film, comprising the following steps.

[0026] (1) Clean the substrate ultrasonically with acetone solution first, then ultrasonically clean it with deionized water, and finally clean it ultrasonically with absolute ethanol and dry it; (2) Put the dried substrate in step (1) Put it into the octadecyltrichlorosilane-toluene solution with a concentration of 2%, let it stand for 45 minutes, take it out, and then irradiate it with ultraviolet light for 30 minutes; (3), put V 2 o 5 and ascorbic acid dissolved in water, V 2 o 5 The mass ratio of ascorbic acid and ascorbic acid is 1:3, add dilute HCl solution and acetic acid solution to adjust the pH to 6, heat to 40°C and stir for 50 minutes to dissolve into a transparent and clear blue solution A; dissolve cerium acetate and ammonium paratungstate in water, (cerium acetate The mass is V 2 o 5 2% of the mass, the mass of ammonium paratungstate is V 2 o 5 3% of the ...

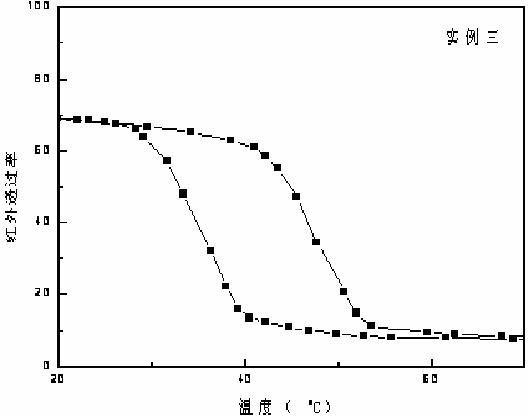

example 3

[0028] A method for preparing a self-assembled vanadium oxide film, comprising the following steps.

[0029] (1) Clean the substrate ultrasonically with acetone solution first, then ultrasonically clean it with deionized water, and finally clean it ultrasonically with absolute ethanol and dry it; (2) Put the dried substrate in step (1) Put it into the octadecyltrichlorosilane-toluene solution with a concentration of 4%, let it stand for 60 minutes, take it out, and then irradiate it with ultraviolet light for 20 minutes; (3), put V 2 o 5 and ascorbic acid dissolved in water, V 2 o 5 The mass ratio of ascorbic acid and ascorbic acid is 1:4, add acetic acid solution to adjust the pH to 5, heat to 50°C and stir for 60 minutes to dissolve into a transparent and clear blue solution A; dissolve cerium acetate and ammonium paratungstate in water, and the masses of cerium acetate and ammonium paratungstate are respectively V 2 o 5 3% and 5% of the mass, add dilute HCl to adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com