Detachable optical glass successive melting furnace

An optical glass and melting furnace technology, applied in glass production, furnaces, boilers, etc., can solve the problems of glass liquid leakage, damage, aging of platinum utensils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

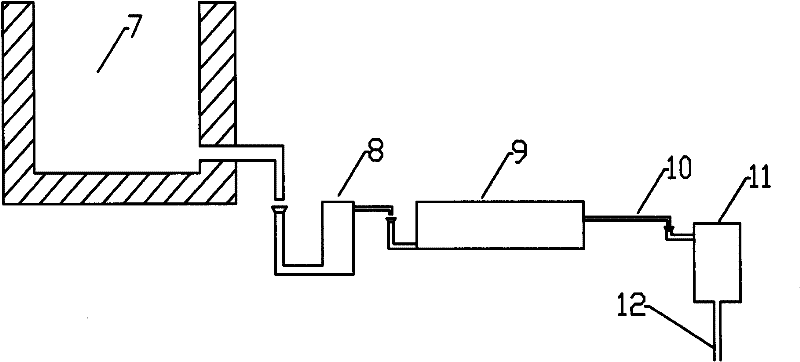

[0015] The device of the present invention is as figure 2 As shown, it includes a melting furnace 7 , a heating furnace 8 , a clarifying furnace 9 , a cooling portion 10 , a working furnace 11 , and a leakage pipe 12 . The furnace 7 of the melting part, the furnace 8 of the heating part, and the furnace 9 of the clarification part are connected through pipelines, and the furnace 9 of the clarification part, the pipeline 10 of the cooling part, and the furnace 11 of the working part are connected in sequence, and the pipe ports are non-contact connected to form a flow channel of molten glass.

[0016] figure 2 The melting furnace 7 in the middle melting part can be a container made of ceramic crucible, quartz crucible, refractory material, platinum crucible and the like. The rest of the containers can be platinum crucibles, quartz crucibles, ceramic crucibles or other high temperature resistant metal containers.

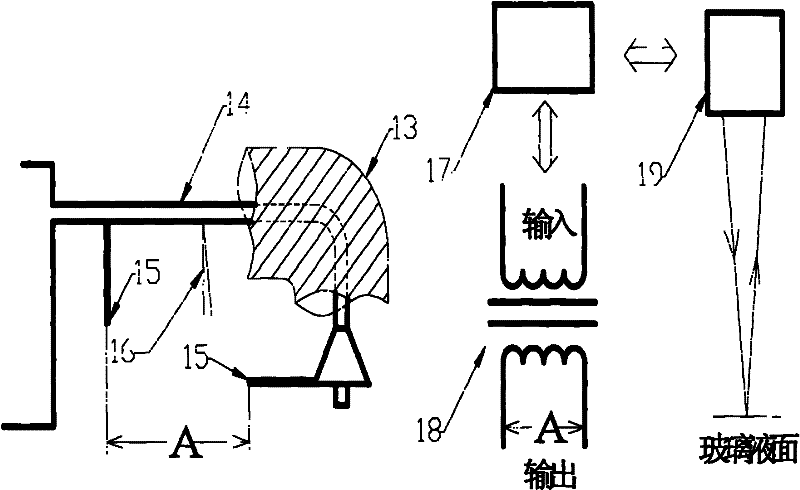

[0017] The detachable optical glass continuous melting furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com