Preparation method of graphene oxide/nano-gold particulate composite material with mono-atomic thickness

A technology of graphene oxide and nano-gold particles, which is applied in the direction of chemical instruments and methods, nanotechnology, and other chemical processes, can solve the problems of inability to realize industrial production and cumbersome methods, and achieve low preparation costs, easy chemical modification, The effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

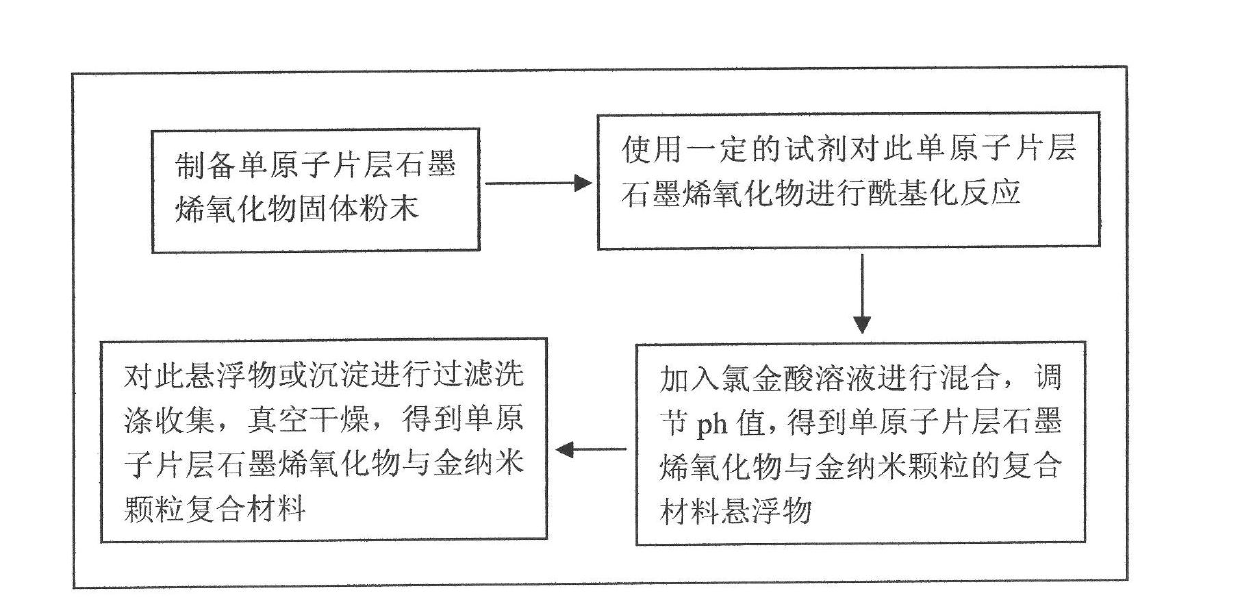

[0033] Such as the preparation process flow figure 1 Said, at first oxidation of acidified expandable graphite is carried out through the following steps: 1. 100ml strong concentrated sulfuric acid is added in the flask, and the magnetic rotor is placed in the flask. The flask was ice bathed. 2 The concentrated acid was stirred and then cooled in an ice bath for 15 minutes, then 20 g of acidified expandable graphite was added to the concentrated acid and stirred at high speed. 3. Add 15g of potassium permanganate powder with a certain particle size within 1 hour. The adding process needs to be slow to avoid violent temperature rise. Control the adding speed and keep the liquid temperature in the beaker not exceeding 3°C. 4 After the addition of potassium permanganate is complete, remove the ice bath. 5 Slowly add 400ml of deionized water, heat the solution, and raise the temperature of the solution to 100°C. Keep it for 0.5-2h. 6 Remove the water bath, stir the reactant, a...

Embodiment 2

[0040] Such as the preparation process flow figure 1 Described, at first acidified expandable graphite is oxidized, is to carry out by following steps: 1, the mixed acid of 50ml strong concentrated sulfuric acid and concentrated nitric acid 1: 1 ratio is joined in the flask, and magnetic rotor is placed in the flask. The flask was ice bathed. 2 The concentrated acid was stirred and then cooled in an ice bath for 15 minutes, then 15 g of acidified expandable graphite was added to the concentrated acid and stirred at high speed. 3 Slowly add 12g of potassium permanganate powder with a certain particle size within 45 minutes to avoid violent temperature rise, control the adding speed, and keep the liquid temperature in the beaker not exceeding 3°C. 4 After the addition of potassium permanganate is complete, remove the ice bath. 5 Slowly add 400ml of deionized water, heat the solution, and raise the temperature of the solution to 100°C. Keep for 1h. 6 Remove the water bath, st...

Embodiment 3

[0047] (1) Graphene carries out acylation reaction: add solvent in graphene oxide, then add reaction reagent, under the condition of protective nitrogen, adjust reaction temperature to be 50-85 degrees Celsius, stir, use oil bath to carry out reflux, reflux time For 1-24h, after reflux, carry out vacuum distillation treatment;

[0048] (2) The THF solution of chloroauric acid is added in the functionalized solution of the above-mentioned monoatomic sheet-layer graphene oxide, then carry out stirring reaction, and the temperature is 50-65 degrees Celsius;

[0049] (3) Adjust the pH value to obtain a mixture solution precipitation, which is filtered to obtain a graphene oxide / gold nanoparticle composite material.

[0050] The reactants used and proportioning are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com