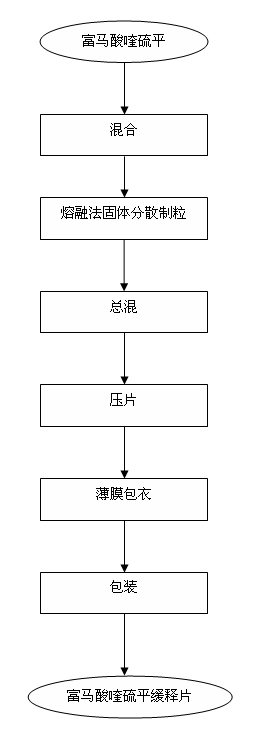

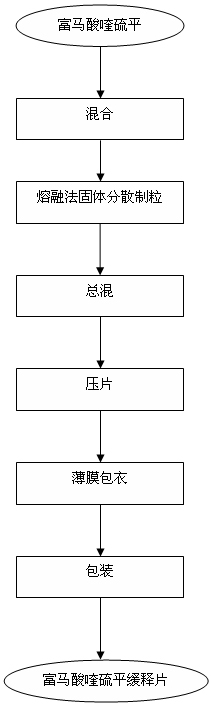

Preparation process of quetiapine fumarate slow release tablet

A technology of quetiapine fumarate and quinoline fumarate, which can be used in drug delivery, oil/fat/wax inactive ingredients, nervous system diseases, etc., and can solve the problems that the sustained-release tablet technology has not been reported in the literature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of Quetiapine Fumarate 50 mg, 200mg, 300mg, 400mg Sustained Release Tablets

[0035] prescription

quantity

content%

Quetiapine Fumarate

230.4 mg mg

46.08%

Kollicoat MAE 100P

69.6mg

13.92%

25mg

5.00%

hydrogenated castor oil

50mg

10.00%

110mg

22.00%

Micropowder silica gel

10mg

2.00%

5mg

1.00%

Total

500mg

100%

[0036] 1) Pass quetiapine fumarate through a 100-mesh sieve, pass hydrogenated castor oil through a 100-mesh sieve, add Sichuan wax powder and Kollicoat MAE 100P into a three-dimensional mixer and mix for 15 minutes, and spread the mixture evenly on a stainless steel plate superior.

[0037] 2) Put the stainless steel plate from operation 1) into an oven and heat it to 100°C, continue heating for 2 hours, take out the stainless steel plate from the oven and cool it down to r...

Embodiment 2

[0046] Preparation of Quetiapine Fumarate 50 mg, 200mg, 300mg, 400mg Sustained Release Tablets

[0047] prescription

quantity

content%

230.4mg

41.89%

Kollicoat MAE 100P

69.6mg

12.65%

30mg

5.46%

hydrogenated castor oil

55mg

10.00%

145mg

26.36%

Micropowder silica gel

15mg

2.73%

5mg

0.91%

Total

550mg

100%

[0048] 1) Pass quetiapine fumarate through a 100-mesh sieve, pass hydrogenated castor oil through a 100-mesh sieve, add Sichuan wax powder and Kollicoat MAE 100P into a three-dimensional mixer and mix for 15 minutes, and spread the mixture evenly on a stainless steel plate superior.

[0049] 2) Put the stainless steel plate from operation 1) into an oven and heat it to 100°C, continue heating for 2 hours, take out the stainless steel plate from the oven and cool it down to room ...

Embodiment 3

[0058] Preparation of Quetiapine Fumarate 50 mg, 200mg, 300mg, 400mg Sustained Release Tablets

[0059] prescription

quantity

content%

Quetiapine Fumarate

230.4 mg mg

38.40%

Kollicoat MAE 100P

69.6mg

11.60%

Sichuan wax powder

35mg

5.83%

hydrogenated castor oil

60mg

10.00%

180mg

30.00%

Micropowder silica gel

20mg

3.33%

5mg

0.84%

Total

600mg

100%

[0060] 1) Pass quetiapine fumarate through a 100-mesh sieve, pass hydrogenated castor oil through a 100-mesh sieve, add Sichuan wax powder and Kollicoat MAE 100P into a three-dimensional mixer and mix for 15 minutes, and spread the mixture evenly on a stainless steel plate superior.

[0061] 2) Put the stainless steel plate from operation 1) into an oven and heat it to 100°C, continue heating for 2 hours, take out the stainless steel plate from the oven and cool it down to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com