Enzyme fuel cell anode and preparation method thereof

A fuel cell and anode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of short lifespan and low power of enzymes, and achieve the effects of high-efficiency oxidation capacity, prolonging lifespan, and increasing current power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

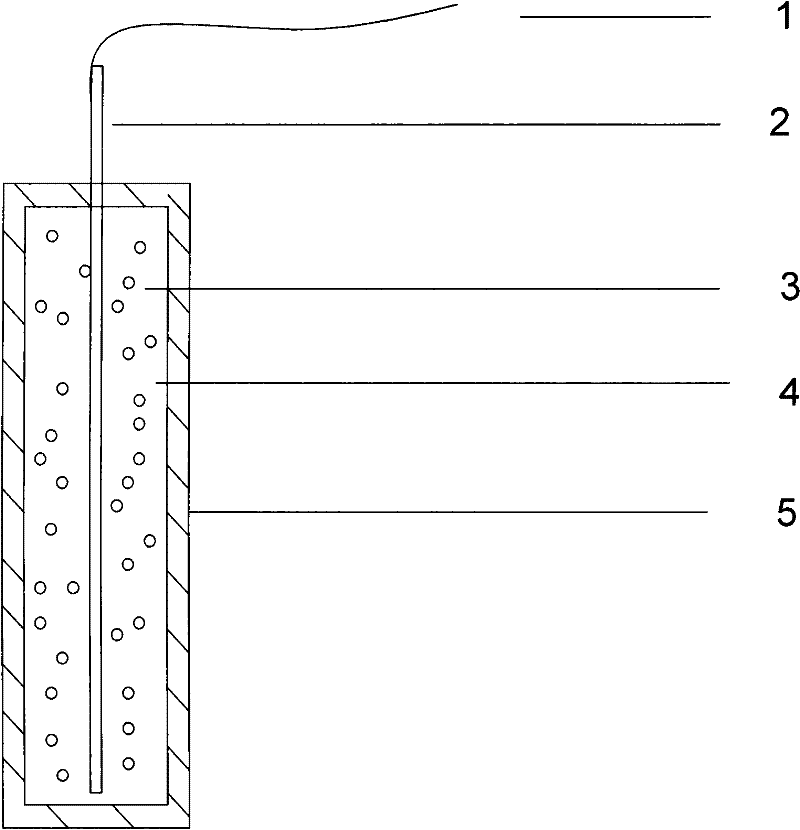

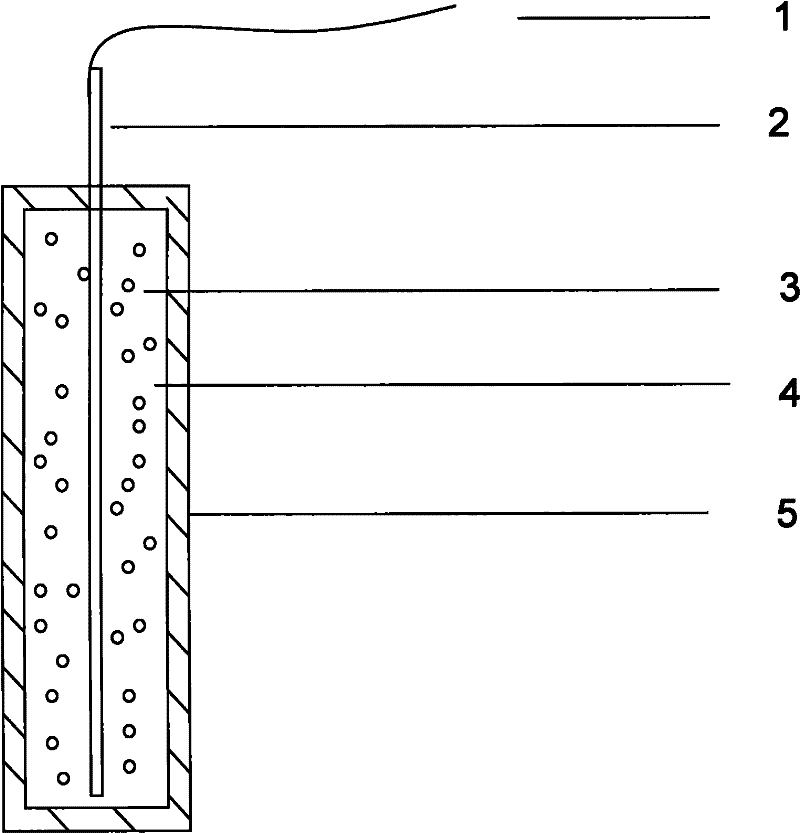

[0015] exist figure 1 In the process, the enzyme crude extract of Gluconobacter oxydans is mixed with 3%-5% chitosan solution evenly, and then immersed in 3% sodium alginate aqueous solution together with the graphite electrode to form chitosan / sodium alginate gel, and then immersed in 5% calcium chloride aqueous solution to form a calcium alginate gel structure outside the chitosan / sodium alginate gel.

Embodiment 2

[0017] The composition of this example is basically the same as that of Example 1, except that the enzyme used is dehydrogenase separated and purified from the crude enzyme extract.

Embodiment 3

[0019] The composition of this example is basically the same as that of Example 1, except that the enzyme used is the oxidase isolated and purified from the crude enzyme extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com