Method for measuring relation curve of forward voltage and junction temperature of LED (Light Emitting Diode) in lamp

A technology of forward voltage and relationship curve, which is applied in the direction of lamp test and single semiconductor device test, etc., can solve the problem of inability to measure the junction temperature of PN junction, etc., and achieve junction temperature and thermal resistance that are convenient for actual work, easy to use, and high measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

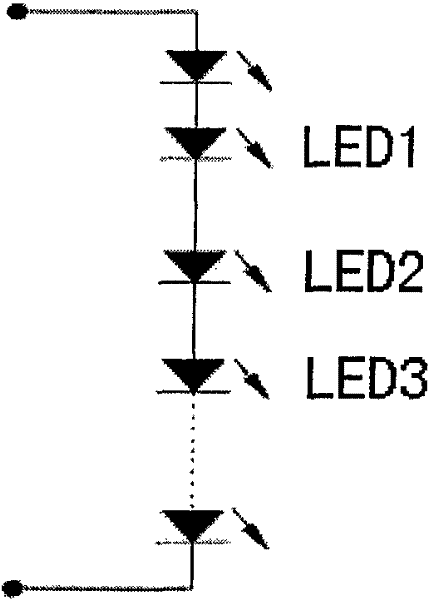

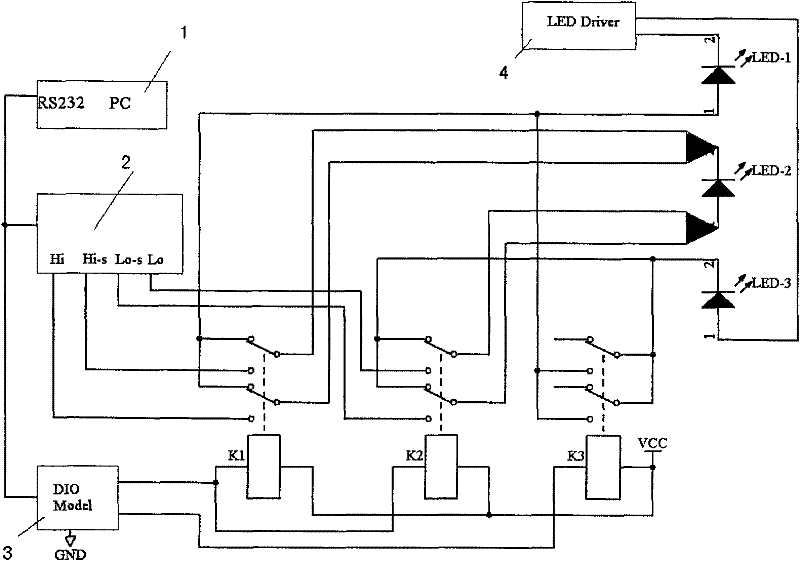

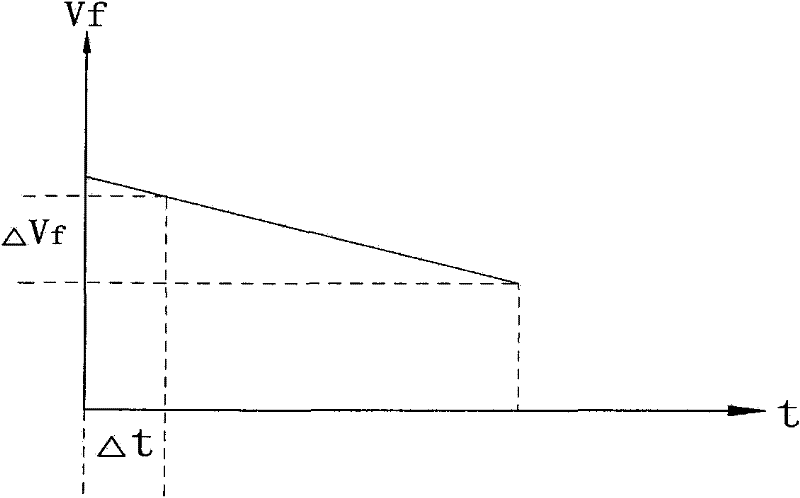

[0014] The LED matrix in the luminaire using LED (see Figure 1a ) in a certain series LED group in the middle, a tested LED at or close to the middle part, that is, the two connecting wires of LED-2 in the figure are cut off, and are connected through three 2-knife 2-throw switching relays to form a Figure 1b , so that the LED under test is connected to the disconnected part or the constant current source of the above-mentioned series LED group through the three 2-knife and 2-throw switching relays, and the working position is when the tested LED is connected to the disconnected part of the above-mentioned series LED group , When the LED under test is connected to the constant current source, it is the measurement position. First, adjust the three 2-knife, 2-throw switching relays to the measurement position. At the heat sink of the LED (the LED comes with a small heat sink), stick a thermoelectric cube and connect the thermoelectric cube to the thermometer. Figure 1b Among...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com