High-temperature-resistant dispersed fluid loss agent for oil well cement and preparation method thereof

A fluid loss reducing agent, oil well cement technology, applied in chemical instruments and methods, drilling composition and other directions, can solve problems such as high cement slurry consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

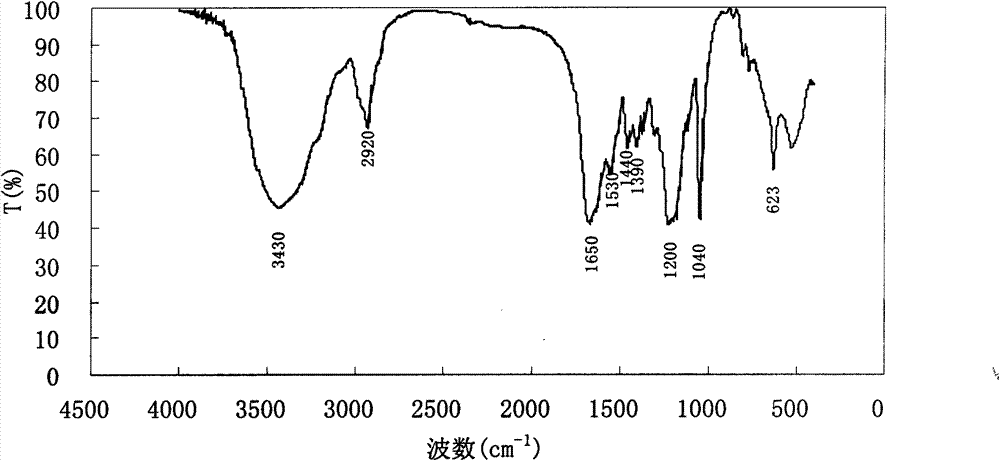

[0018] Embodiment 1 illustrates the preparation method of high temperature resistant dispersed oil well cement fluid loss reducer

[0019]Weigh 61.4 parts of 2-acrylamido-2-methylpropanesulfonic acid (AMPS), 18.3 parts of N, N'-dimethylacrylamide (DMAA), 13.07 parts of acrylamide (AM), maleic anhydride (MA ) 7.23 copies. Dissolve in 308 parts of deionized water, add an appropriate amount of sodium hydroxide solution, and adjust the pH value to 7. Add the solution into the three-necked flask, put the three-necked flask into a constant temperature water bath at 40°C, start stirring, and pass nitrogen into the three-necked flask to remove oxygen. After the temperature of the aqueous solution in the three-necked flask reaches 40°C, add 4 parts of The mass concentration of ammonium sulfate and sodium bisulfite is 10% of the mixed solution to initiate the reaction, and the reaction lasts for 5 hours to prepare a tetrapolymer solution, which is dried and pulverized to obtain a dispe...

Embodiment 2

[0020] Example 2, Evaluation of the fluid loss reducing performance of the oil well cement fluid loss reducing agent of the present invention

[0021] Add a certain mass percentage (based on the cement quality) of powder sample 1 in Shengwei Oil Well G grade cement, prepare cement slurry with a water-cement ratio of 0.44 according to the GB10238-88 standard, and then press the People's Republic of China Petroleum and Natural Gas Industry Standard SY / T 5960-94 "Evaluation method of oil well cement fluid loss reducer" measures the water loss of sample 1, and evaluates the water loss reducer performance of sample 1.

[0022] The water loss reduction effect of sample 1 on oil well cement was evaluated according to the above method, and the results are shown in Table 1. Experimental results show that the fluid loss reducing agent for oil well cement of the present invention not only has good fluid loss reducing performance in fresh water solutions within the range of 60°C to 150°C...

Embodiment 3

[0025] Embodiment 3, the dispersibility evaluation of the oil well cement fluid loss reducing agent of the present invention

[0026] Add a certain mass percentage (based on the cement mass) of powder sample 1 to the G-grade cement of Shengwei Oil Well, prepare cement slurry with a water-cement ratio of 0.44 according to the GB10238-88 standard, and according to the Petroleum and Natural Gas Industry Standard SY / T5546 of the People's Republic of China -92 "Test Method for Application Properties of Oil Well Cement" Determination of the rheological properties of the cement slurry added to Sample 1.

[0027] The effect of sample 1 on the rheological properties of cement slurry was evaluated according to the above method, and the test results are shown in Table 2. The experimental results show that the consistency coefficient of the cement slurry added with sample 1 is small. Although the consistency coefficient increases with the increase of the amount of sample 1, the cement slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com