Thermoplastic elastomer composition, foam body and laminated body

A thermoplastic elastomer and composition technology, which can be applied in the directions of synthetic resin layered products, layered products, transportation and packaging, etc., can solve the problems of decreased foam manufacturing efficiency and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

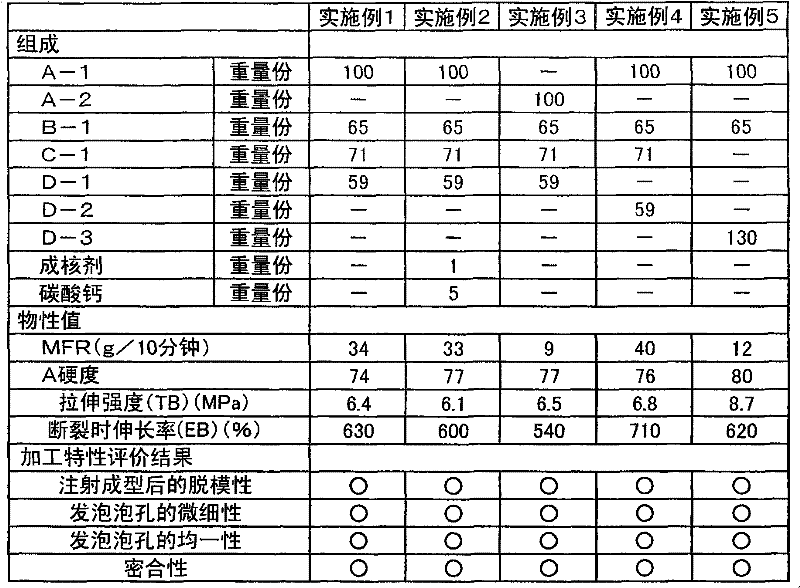

Embodiment 1

[0130] (Preparation of thermoplastic elastomer composition)

[0131] 100 parts by weight (4,080 g) of the hydrogenated product of A-1 styrene-conjugated diene-styrene block copolymer, B-1 propylene-based Resin, 71 parts by weight (2,880 g) of C-1 mineral oil softener per 100 parts by weight of A-1, 59 parts by weight (2,400 g) of D-1 ethylene-propylene copolymer per 100 parts by weight of A-1 0.05 parts by weight (6 g) of erucamide (trade name NEUTRON S manufactured by Nippon Seika Co., Ltd.), 0.05 parts by weight of rubber and 100 parts by weight in total of A-1, B-1, C-1, and D-1 Parts (6g) of calcium stearate, 0.15 parts by weight (18g) of antioxidant (trade name IRGANOX 1010 manufactured by Ciba Specialty Chemicals Co., Ltd.: 0.1 parts by weight (12g), product name Ultranox 626 manufactured by GE Specialty Chemicals Co., Ltd.: 0.05 parts by weight (6 g)), melted and kneaded with a 16L Banbury Kneader manufactured by Kobe Steel at a rotation speed of 68 rpm, and then molded ...

Embodiment 2

[0137] As additives, a nucleating agent (comprising polypropylene masterbatch manufactured by Nippon Physical and Chemical Co., Ltd., trade name Gel AllD 10% / Milliken & Company, trade name HYPERFORM HPN-68L 1.7%), calcium carbonate, and Other than that, it carried out similarly to Example 1. Table 1 shows the evaluation results.

Embodiment 3

[0139] In addition to using the hydrogenated styrene-conjugated diene-styrene block copolymer of A-2 instead of the hydrogenated styrene-conjugated diene-styrene block copolymer of A-1, and Example 1 was carried out in the same manner. Table 1 shows the evaluation results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com