Technique for drying para-aramid micropowder by recycling inert gas

A para-aramid and inert gas technology, which is applied in the field of inert gas circulation para-aramid micro-powder drying process, can solve the problems of uneven particle size of aramid polymer, complicated process and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

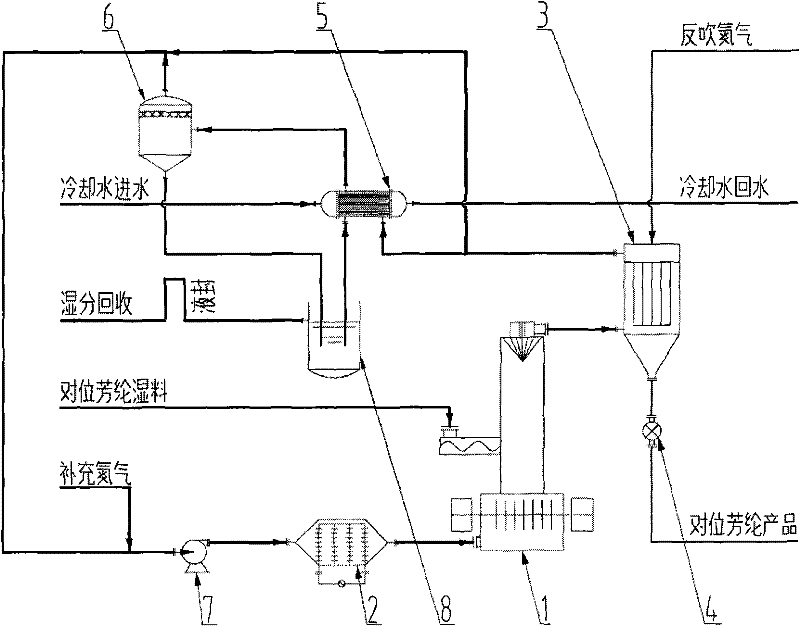

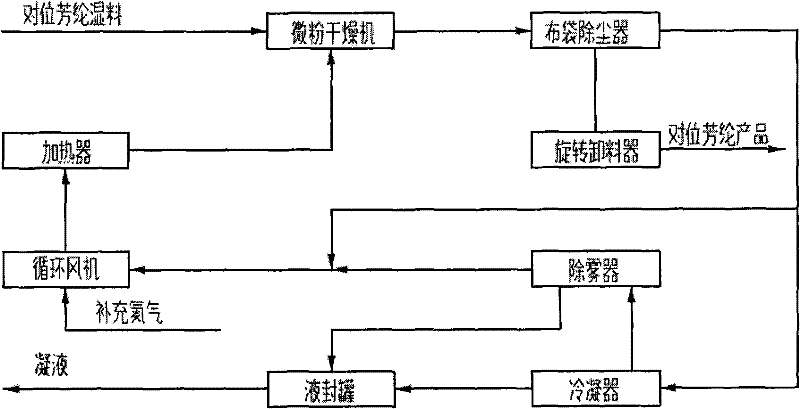

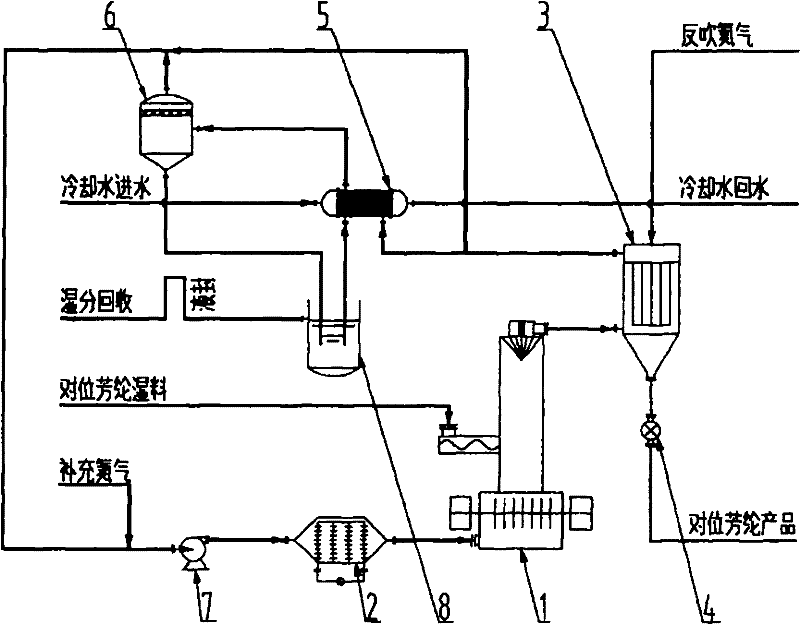

[0014] Below in conjunction with accompanying drawing, the technical scheme of the invention is described further:

[0015] Such as Figure 1-2 As shown, the para-aramid wet material is added to the micro-powder dryer with its own feeding screw, and the disperser at the bottom of the micro-powder dryer breaks up and breaks up the para-aramid wet material added to the dryer. The micro powder dryer includes a drying body, a cylinder, a feed inlet, a discharge (air) outlet, a hot air inlet, etc. A crusher is installed between the lower feed inlet and the hot air inlet of the main body of the dryer, and is connected to the main shaft. , In the barrel of the main body of the dryer, classifiers are provided on the upper part and the discharge section, and are connected to the rotating shaft (patent number: zl2262102.41, produced by Lanzhou Ruide Drying Technology Co., Ltd.). The para-aramid fibers dispersed by the internal crusher of the micro-powder dryer fully contact and dry wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com