Device and method for slag afterheat self-decomposition

A technology of waste heat self-decomposition and steel slag, which is applied in the field of converter steel slag treatment and steel slag waste heat self-decomposition treatment device under pressure, which can solve the problems of poor gelling performance, high equipment failure rate, equipment wear, etc. Good chemical effect and short processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

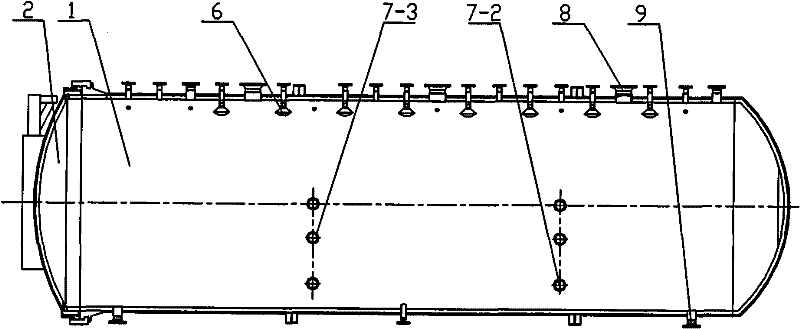

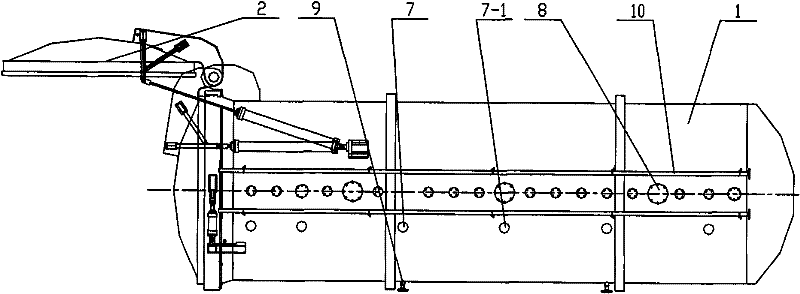

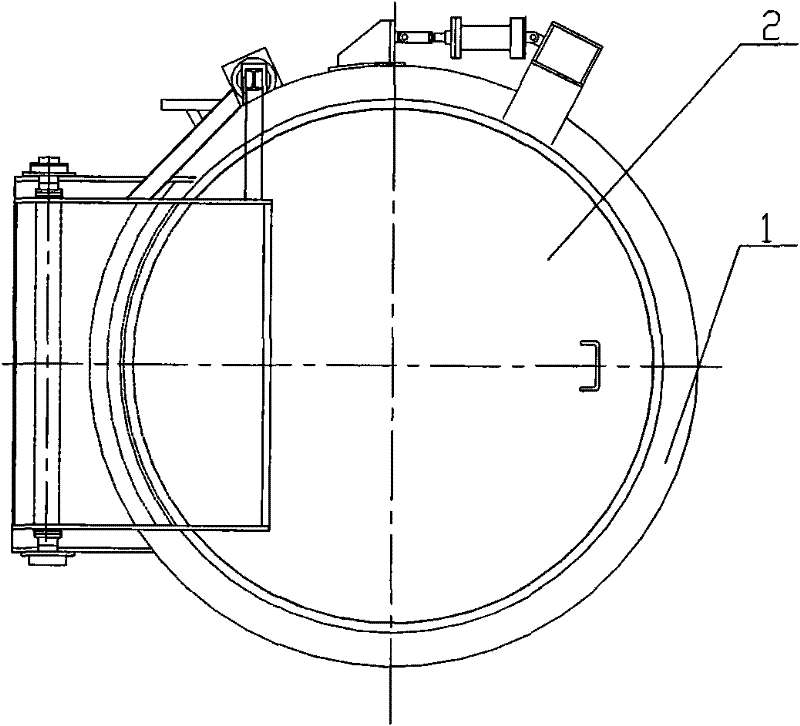

[0022] like figure 1 , 2 , 3 is a schematic structural diagram of a steel slag waste heat self-decomposing treatment device under pressure in the present invention, including a waste heat self-decomposing tank body 1, a tank door 2, a slag tank 3, a slag tank support 4, a slag transporting track 5, and a water spray device 6 , a control device 7, an exhaust device 8, a drainage device 9 and a cooling system 10; wherein the control device includes a pressure detection device 7-1, a temperature detection device 7-2 and a safety device 7-3.

[0023] The waste heat self-discharging tank body 1 is a horizontal cylindrical pressure vessel with a tank door 2 at one end; the waste heat self-discharging tank body 1 and the tank door 2 are used to form a closed space, so that the steel slag is sealed here. Self-decomposing powder in space.

[0024] The slag tank 3 is a clamshell structure, divided into left and right halves, the two halves can rotate around the central shaft, and can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com