Supercritical water oxidation reactor by using auxiliary fuel for supplying heat

A technology of supercritical water oxidation and auxiliary fuel, applied in the direction of pressure vessels used in chemical processes, methods of chemically changing substances by using atmospheric pressure, chemical instruments and methods, etc., to promote efficient mixing and combustion, ensure safe operation, The effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

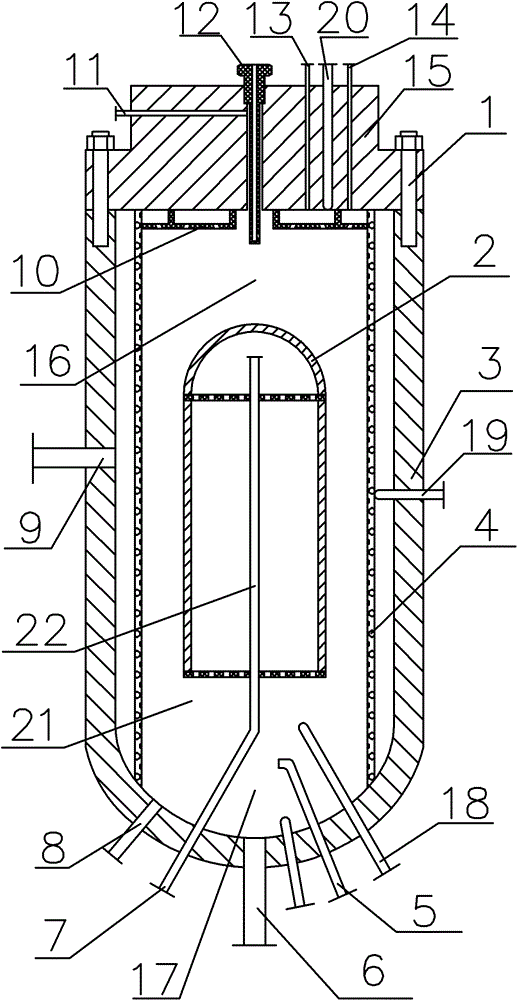

[0023] Such as figure 1 As shown, a supercritical water oxidation reactor using auxiliary fuel to supply heat, the end cover 15 and the kettle body 3 are combined by fastening bolts 1 to form a closed reaction space. The space between the end cover 15 and the top of the dome of the catalyst box is a high-temperature combustion zone 16, the area below the catalyst box is a salt separation zone 21, the bottom center of the kettle body is provided with a solid salt discharge port 6, and the area above it is a subcritical salt-dissolving zone 17.

[0024] The fuel core tube 12 is arranged in the center hole of the end cover along the axial direction of the end cover, and is fixed in the end cover by thread sealing. The fuel core tube is a fuel (methanol) delivery pipeline, and its lower end extends out of the end cover and reaches above the high temperature combustion zone 16. The outlet at the lower end of the fuel core tube is designed as a blind hole structure, and when the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com