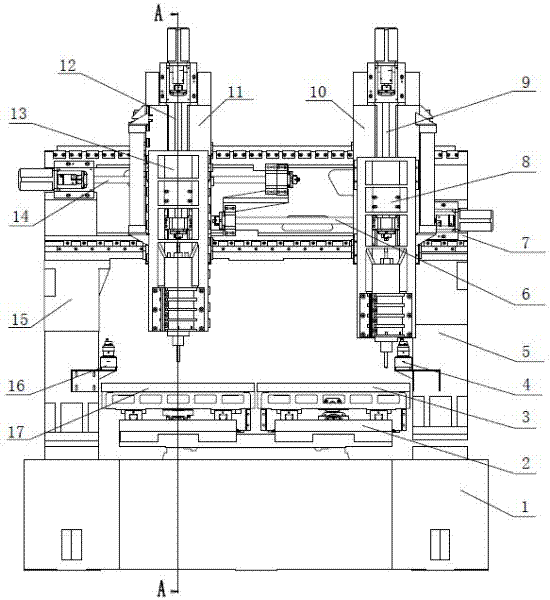

Numerical control double-station mould engraving and milling machine

An engraving and milling machine, dual-station technology, applied in the direction of manufacturing tools, metal processing mechanical parts, milling machines, etc., can solve problems such as productivity limitations, uneven operating proficiency, and difficult to guarantee requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

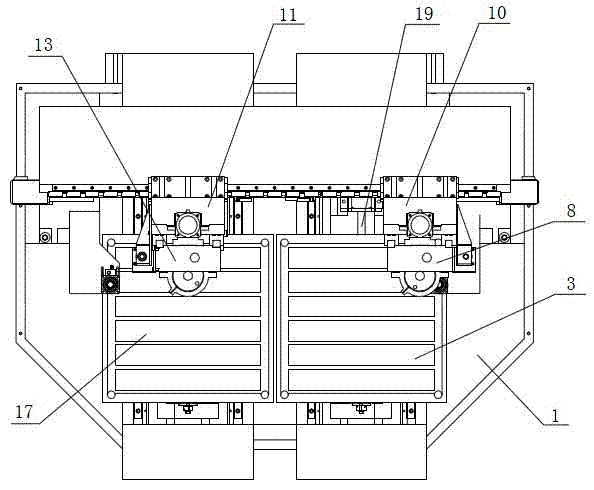

[0014] The present invention will be further explained below in conjunction with the drawings in the specification:

[0015] The CNC double-station mold engraving and milling machine includes a machine frame body 1. The machine frame body 1 is matched with a base 2, a left column 15 and a right column 5, and a cross beam 7 is arranged above the left column 15 and the right column 5. 7 The left X-axis linear slider guideway pair and the right X-axis linear slider guideway pair are respectively connected with the left X-axis sliding table 11 and the right X-axis sliding table 10, and respectively through the left X-axis ball screw pair 14, right The X-axis ball screw pair 6 is matched in transmission. The left X-axis sliding table 11 and the right X-axis sliding table 10 can perform related left and right movements on the beam 7 or one side is stationary and the other moves independently; the base 2 The left Y-axis linear slider guideway pair and the right Y-axis linear slider guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com