Production method for a paint plant component and corresponding paint plant component

A technology of spraying equipment and production method, which is applied in the production of components and the field of production of spraying equipment components, can solve the problems of no coating equipment component reference, etc., and achieve the effect of low weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

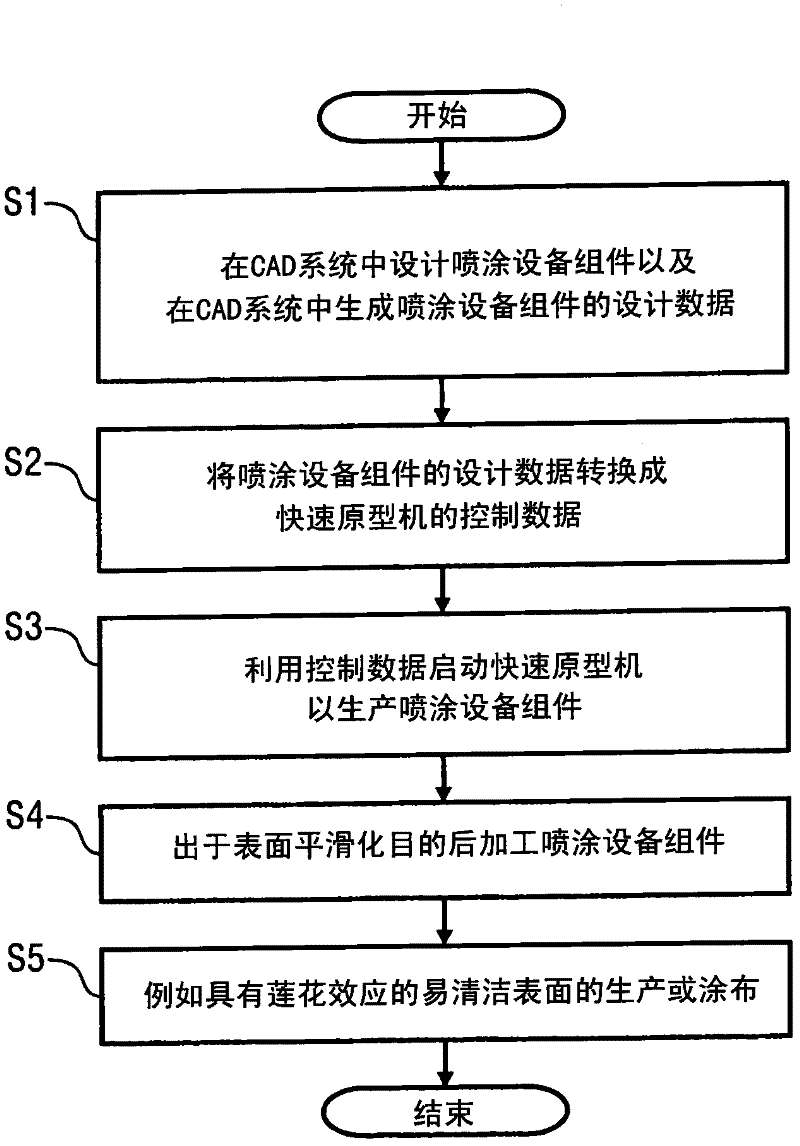

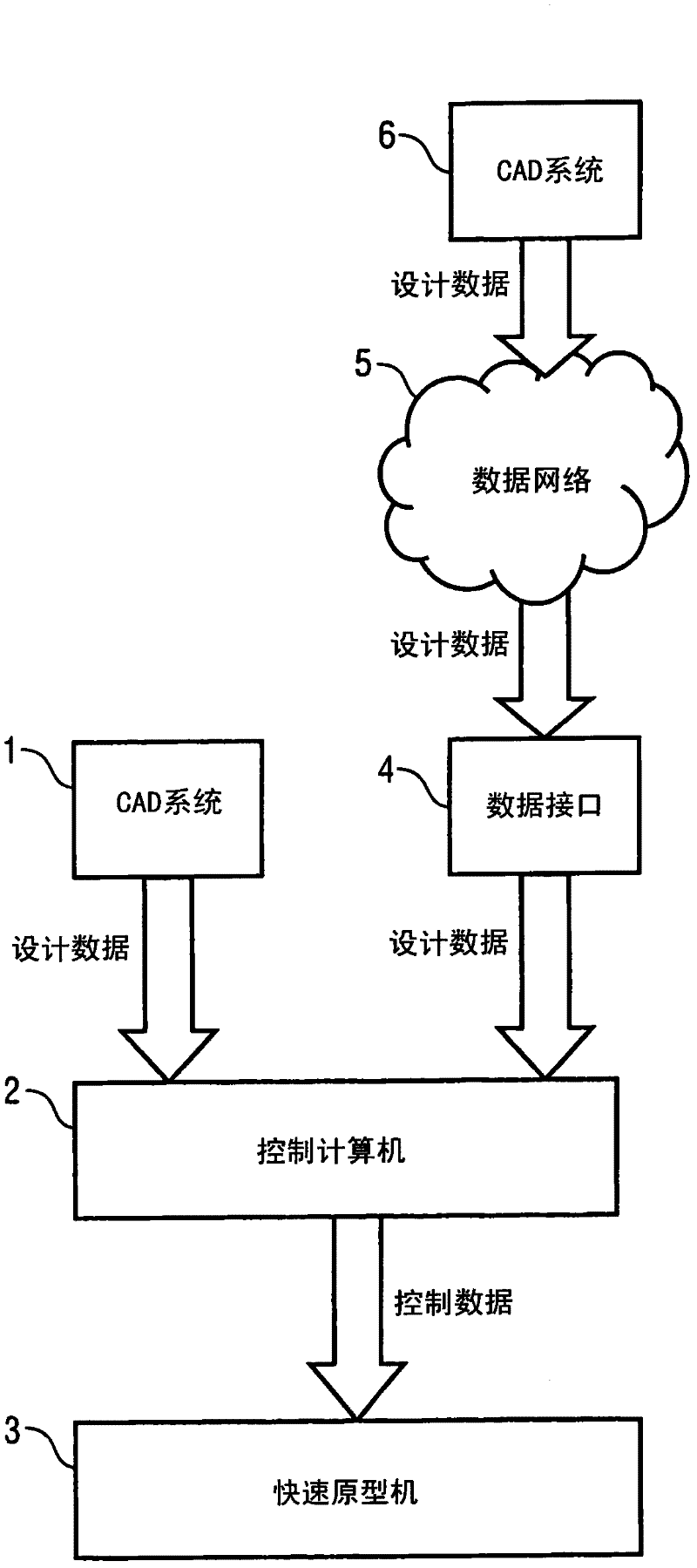

[0078] in such as figure 1 In the illustrated production method according to the invention, firstly, in a first step S1 , the spraying system component is designed in the conventional manner in a CAD system, in which design data for the spraying system component are generated. By way of example, the design data here can be in the known STL format (STL: Standard Triangulation Language), but other data formats are also possible in principle.

[0079] In the next step S2, the painting equipment component design data are then converted into control data for the rapid prototyping machine. The rapid prototyping machine may for example be a machine of the type EOSINT P390, P700 or P730 or FORMIGA P100 commercially available from EOS Corporation.

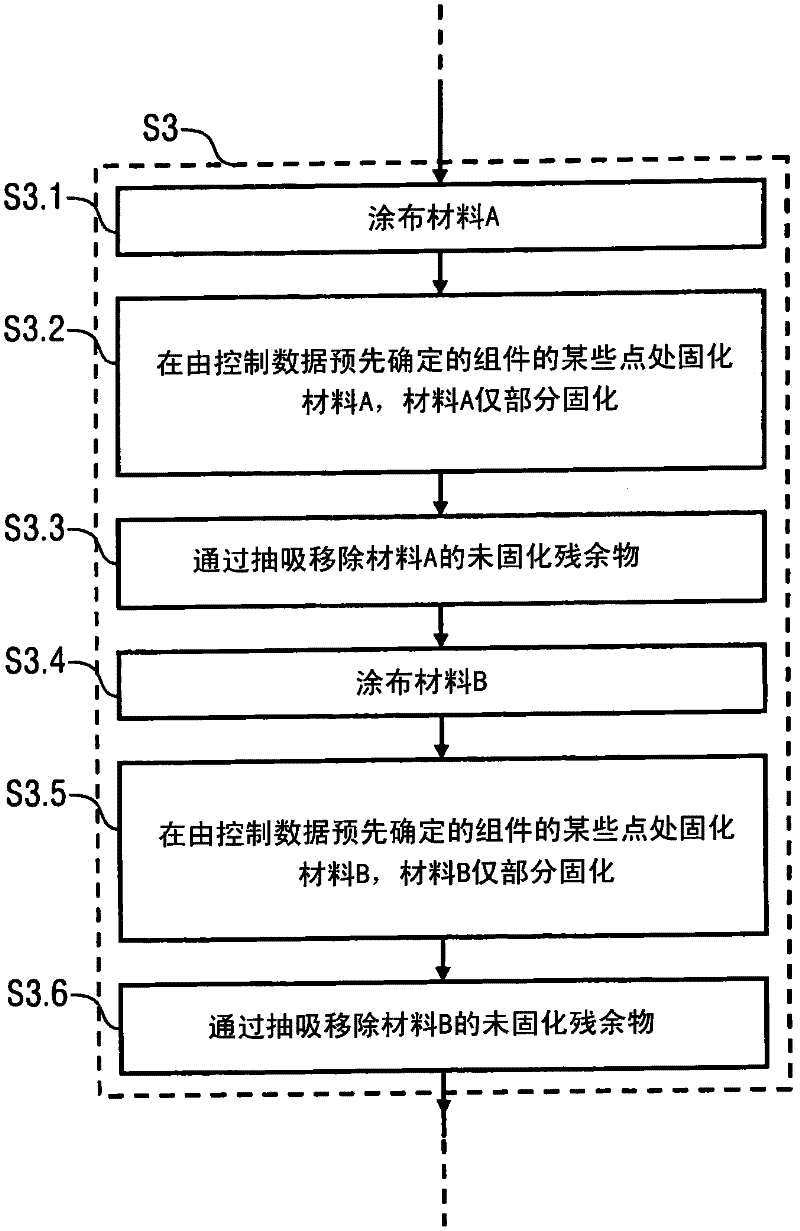

[0080] In a next step S3, the rapid prototyping machine is then started with the control data to produce the spraying equipment components.

[0081] Subsequent processing of the coating system components for the purpose of surface smoothi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com