Ionizing ray shielding protective plate and manufacturing method thereof

A technology of shielding protection and ionizing radiation, applied in shielding, reactors, nuclear engineering, etc., can solve the problems of difficult control and high production cost, and achieve the effect of simple equipment and process, low manufacturing cost, and outstanding substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

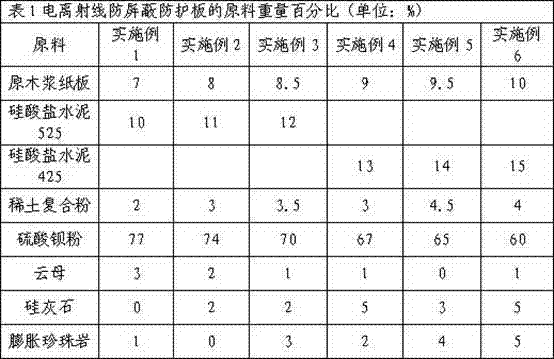

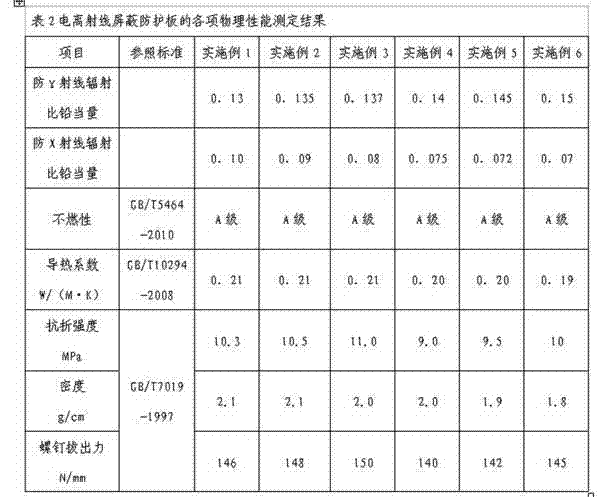

[0042] The raw material weight percentage of the ionizing ray shielding protective plate of the present invention is shown in Table 1.

[0043]

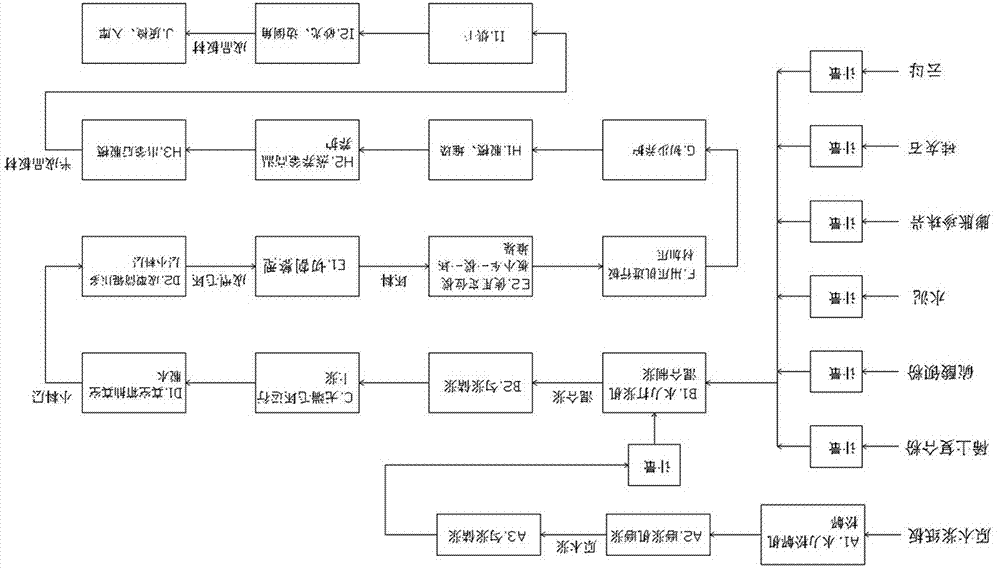

[0044] Combined reference figure 1 , The method of manufacturing ionizing ray shielding protection board according to the raw material ratio in Table 1, includes the following steps:

[0045] Step A, prepare raw wood pulp

[0046] A1. Put the raw wood pulp cardboard into the hydraulic loosening machine and add water to loosen it;

[0047] A2. Refined by a refiner to obtain raw wood pulp;

[0048] A3. The raw wood pulp is sent to the slurry storage tank for slurry storage and homogenization.

[0049] Step B, mixing pulping

[0050] B1. Cement, rare earth composite powder, barium sulfate powder, mica, siliceous lime, expanded perlite and the raw wood pulp (equivalent to raw wood pulp cardboard) of step A are respectively measured according to the proportions in Table 1 and then poured into a hydraulic beater to mix. Mixed pulp

[0051] B2. Send t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com