Special slurry for sizing warp containing polyester staple fibers

A polyester staple fiber, warp sizing technology, applied in the direction of fiber type, fiber treatment, textile and papermaking, etc., can solve the problems of plugging pipes, difficult to enhance wear resistance and reduce hairiness, unknown impact on textiles, etc., to improve impact resistance. and bending fatigue resistance, improving the balance between penetration and coating, and facilitating performance control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

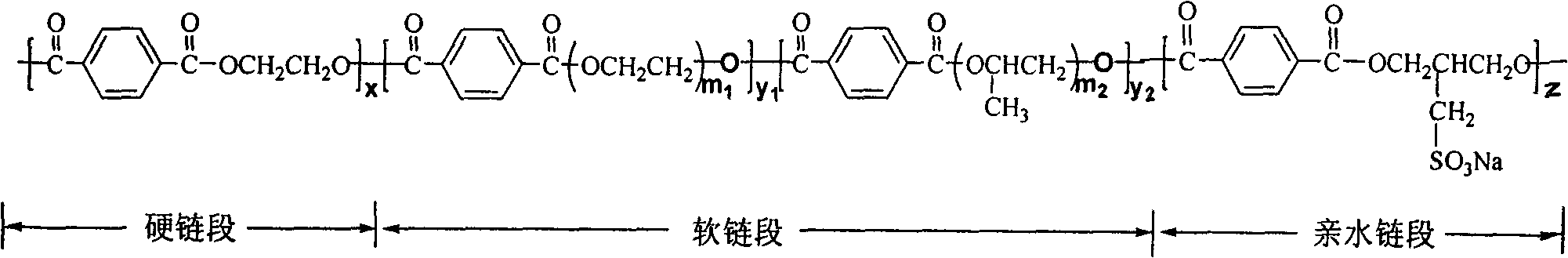

Method used

Image

Examples

Embodiment 1

[0026] Preparation of water-based copolyether ester: Add 166 parts by weight of dimethyl terephthalate, 18.6 parts by weight of ethylene glycol, 300 parts by weight of polyethylene glycol with a relative molecular mass of 1500, and 300 parts by weight of polyethylene glycol with a relative molecular mass of 750 in the polymerization reactor. 75 parts by weight of poly(1,2-propylene glycol), 71.2 parts by weight of sodium 1,2-dihydroxy-3-propanesulfonate, 0.15 parts by weight of tetrabutyl titanate, start the stirring device, heat and mix evenly, and the reaction kettle The temperature rises to 170-180°C to melt the material and carry out the transesterification reaction. When the amount of methanol distilled out is 90% of the theoretical amount, the product is transferred to the polycondensation tank, first replaced with nitrogen for 3 times, and then gradually heated to 200-220°C, after 2 hours of continuous decompression, then at 250-260°C and React under 80-100Pa pressure f...

Embodiment 2

[0029] Preparation of water-based copolyether ester: Add 166 parts by weight of dimethyl terephthalate, 24.8 parts by weight of ethylene glycol, 360 parts by weight of polyethylene glycol with a relative molecular mass of 1500, and 360 parts by weight of polyethylene glycol with a relative molecular mass of 750 in the polymerization reactor. 45 parts by weight of poly(1,2-propylene glycol), 53.4 parts by weight of sodium 1,2-dihydroxy-3-propanesulfonate, 0.1 part by weight of tetrabutyl titanate, start the stirring device, heat and mix evenly, and the reaction kettle The temperature rises to 170-180°C to melt the material and carry out the transesterification reaction. When the amount of methanol distilled out is 90% of the theoretical amount, the product is transferred to the polycondensation tank, first replaced with nitrogen for 3 times, and then gradually heated to 200-220°C, after 2 hours of continuous decompression, then at 250-260°C and React under 80-100Pa pressure for...

Embodiment 3

[0032] Preparation of water-based copolyether ester: Add 166 parts by weight of dimethyl terephthalate, 18.6 parts by weight of ethylene glycol, 600 parts by weight of polyethylene glycol with a relative molecular mass of 2000, and 600 parts by weight of polyethylene glycol with a relative molecular mass of 500 in the polymerization reactor. 50 parts by weight of poly(1,2-propanediol), 53.4 parts by weight of sodium 1,2-dihydroxy-3-propanesulfonate, 0.2 parts by weight of tetrabutyl titanate, start the stirring device, heat and mix evenly, and the reaction kettle The temperature rises to 170-180°C to melt the material and carry out the transesterification reaction. When the amount of methanol distilled out is 90% of the theoretical amount, the product is transferred to the polycondensation tank, first replaced with nitrogen for 3 times, and then gradually heated to 200-220°C, after 2 hours of continuous decompression, then at 250-260°C and React under 80-100Pa pressure for 4 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com